bowers1986

New Member

- Posts

- 165

Will try back flushing it and report back here

Super!

What a result 3 little 5mm holes can make! It's a patented idea by the way.

Don't worry about the temp gauge reading a little high or low. It measures only a very narrow band of temperatures, and leaps up very fast when the temp gets even just a little hotter than usual, or indeed a little lowertemp makes it show a LOT lower.

The thing to observe is, or your gauge, WHAT IS THE NORMAL RUNNING TEMP?

As soon as it gets to that, all is well, but STOP and investigate quickly whenever the temp gauge goes higher than the "normal" level on your dial. Any sudden rise is a fair warning that something might be about to go wrong, and VERY hot.

The proof of the pudding will be taking her for a drive, and a long steady uphill climb.

CharlesY

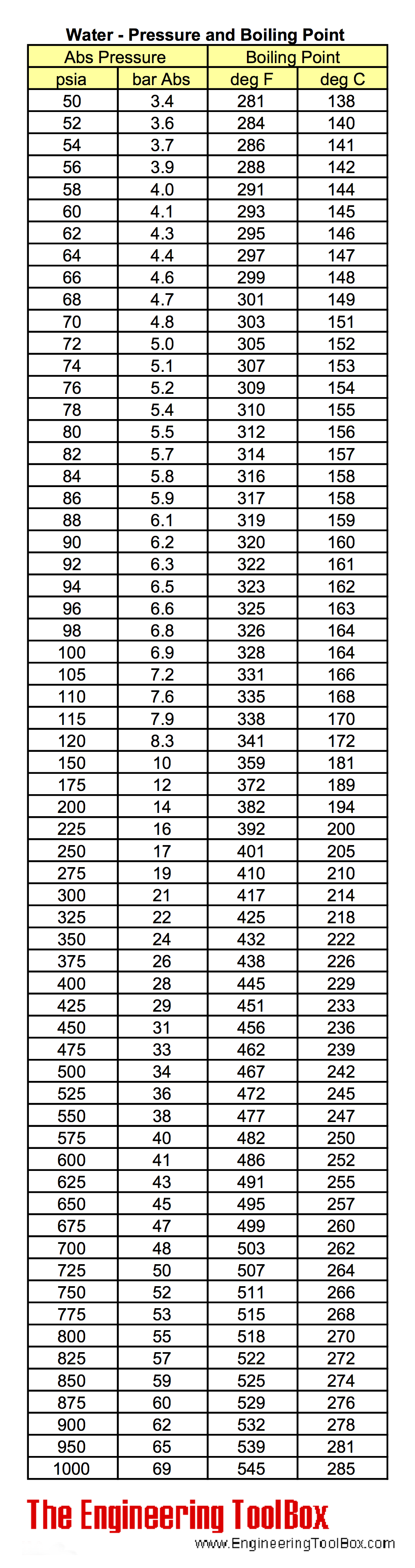

Interesting. I may do the hole in the thermostat mod to mine too. I am running ht since I replaced the radiator with a newer style one. I think my problem is that I am not running it with an expansion tank when I am pretty sure it should. What makes me think this is that the rad cap that came with it is rated at 7PSI...whilst the workshop manual says 9/10 PSI - suggesting it is a lower PSI designed to flow into the expansion tank?

Fair enough, thanks for that.

But as the PSI is lower on the cap that I now have, it will therefore lower the temperature boiling point and make it more likely to come out the expansion pipe at a lower temperature?

I had same symptoms on my series 3 turned out to be air lock in the heater pipes and matrixYip that what it does but if I run longer the hole system heats up the gauge reads slightly under red .

Thanks for the tip mine 2a no heating system in the landy .I had same symptoms on my series 3 turned out to be air lock in the heater pipes and matrix

Welcome To LandyZone, the Land Rover Forums!

Here at LandyZone we have plenty of very knowledgable members so if you have any questions about your Land Rover or just want to connect with other Landy owners, you're in the right place.

Registering is free and easy just click here, we hope to see you on the forums soon!