Toonarf

Active Member

- Posts

- 81

- Location

- Hesketh Bank West Lancashire

Hello Everyone

Welcome to my story about the recommissioning of Boanerges my newly purchased 88inch Series 3 2 ¼ Diesel. My intention is to have a good useable Land Rover, what it will never be is a highly polished show vehicle, I want to use and enjoy it. However the body work is very good with only a few minor dings and dents. This story will not be a total strip down and rebuild onto a new galvanised chassis simply because it had one fitted way back in 1990.........

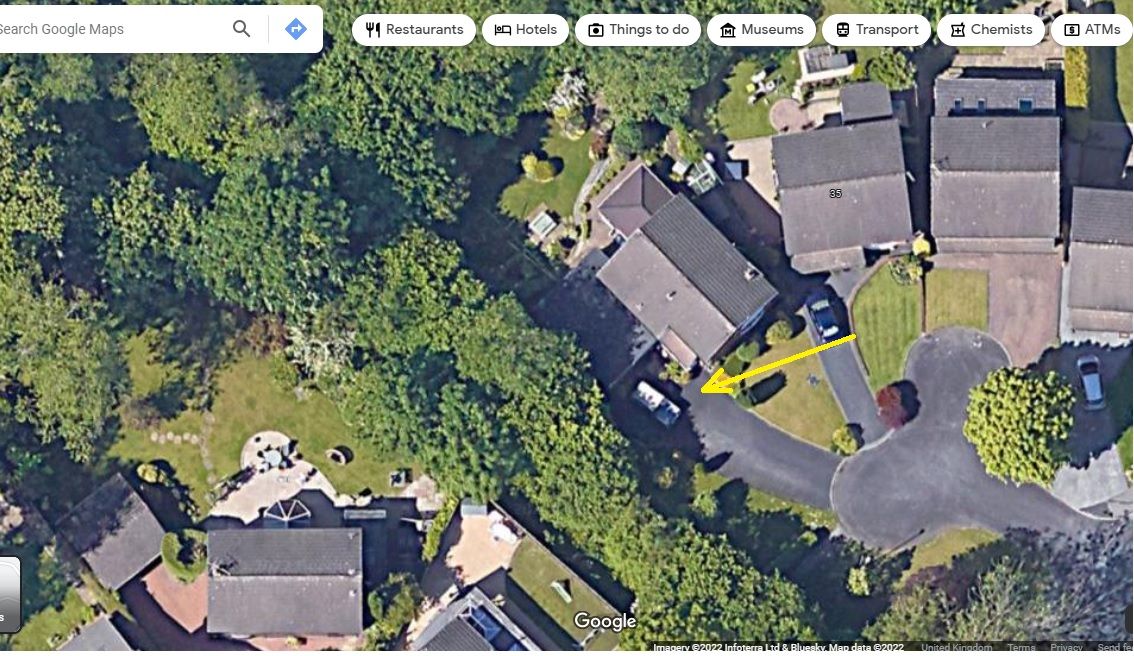

The first picture shows him in his resting place for the last 14 years.

The second picture shows my first view .

Boanerges requires some recommissioning after resting outside for well over a decade, the clutch is supposedly stuck, however I did find the pedal very stiff to press and then it stayed on the floor, further checks revealed no fluid and a very rusted up slave cylinder, so first job is to rebuild the clutch hydraulics and free off the pedal box.

Finally lets see what a bit of Tcut will do for the blue paint.

Thanks for looking

David

Welcome to my story about the recommissioning of Boanerges my newly purchased 88inch Series 3 2 ¼ Diesel. My intention is to have a good useable Land Rover, what it will never be is a highly polished show vehicle, I want to use and enjoy it. However the body work is very good with only a few minor dings and dents. This story will not be a total strip down and rebuild onto a new galvanised chassis simply because it had one fitted way back in 1990.........

The first picture shows him in his resting place for the last 14 years.

The second picture shows my first view .

Boanerges requires some recommissioning after resting outside for well over a decade, the clutch is supposedly stuck, however I did find the pedal very stiff to press and then it stayed on the floor, further checks revealed no fluid and a very rusted up slave cylinder, so first job is to rebuild the clutch hydraulics and free off the pedal box.

Finally lets see what a bit of Tcut will do for the blue paint.

Thanks for looking

David

Last edited: