Apologies for the length and boring nature of this post but I feel the need to unload.

A series2a bitsa with 2.5na motor. Last August it seemed even slower than usual and a compression test made me decide to get a recon head from (let's call them) A Company of Reconditioners of Landrover. All seemed OK with professional looking masking tape over the ports.

Before putting the head on, a quick look at the bores revealed no wear lips but 2 Pistons had a good few mm of side movement and one of the liners had dropped by about 2mm. After a quick panic and deciding I didn't have the time or confidence to rebuild it, I got a 3/4 exchange engine from the afore mentioned company.

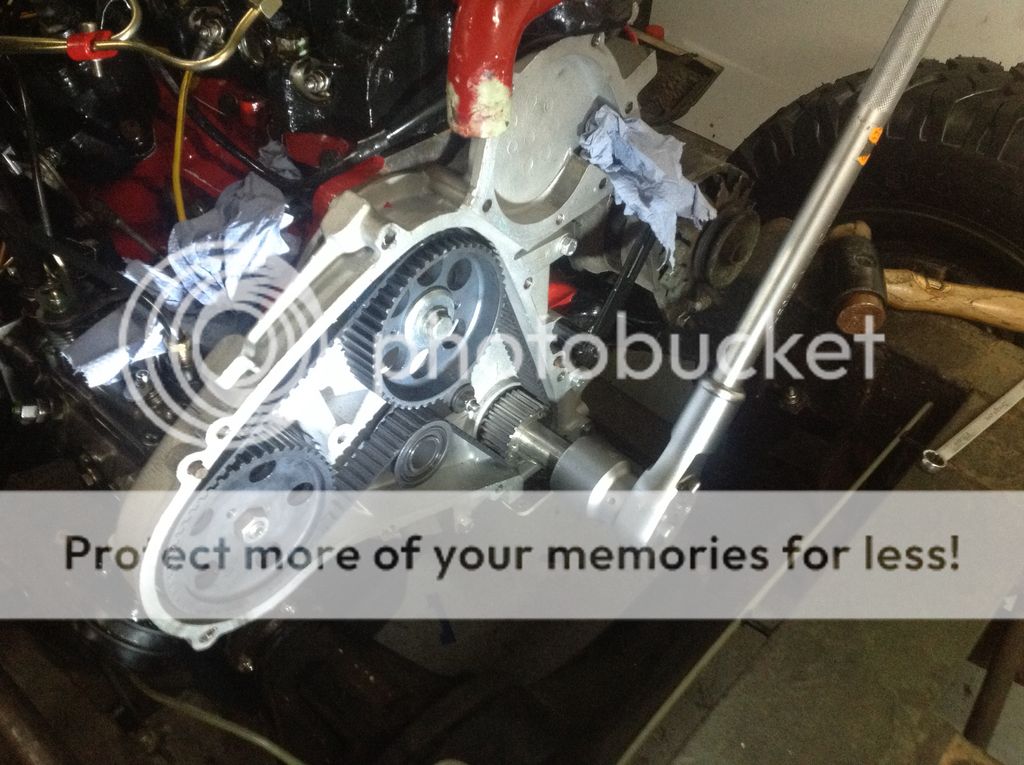

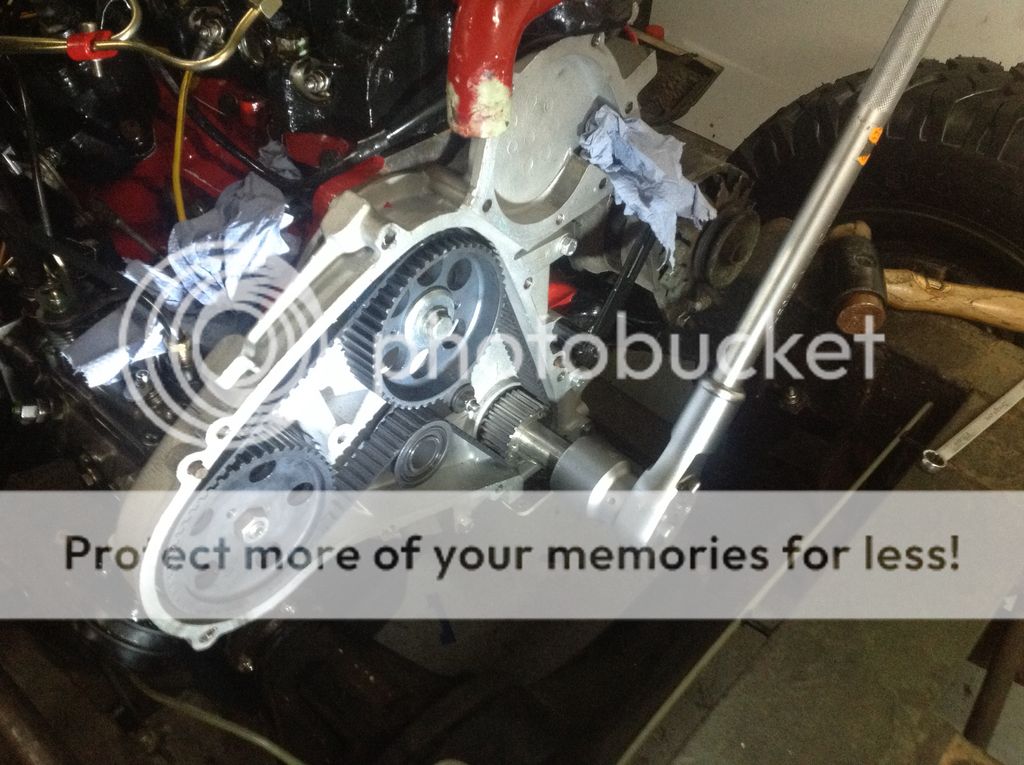

I nailed on the head, put it back in the vehicle but couldn't start it. Lots of headscratching and checking injectors, eventually found no compression. Checked with the company who said i must have timed it wrong so whipped the timing cover and found the cam sprocket was touching the back of the timing cover because the thrust plate was missing. So I removed it sent it back for the thrust plate and lost compression.

Picture with camshaft sticking out.

Returned after a week or so, seemed to have compression when turning it over on the pallet with a spanner so I put it back in the vehicle. Couldn't start it, checked compression straight away-low or none. Checking with a leak down tester showed leaking valves. The recon company said just send it back and they would start it. I wasn't entirely happy as I wanted it soon as possible, so I took the head off and gave it to a company called hamlins in bridgewater who said it was a new casting that hadn't been cleaned properly and the grit was intermittently falling off and blocking the valves. They basically just checked, cleaned it and lapped the valves.

Went to put the head on and noticed a lot of oil underneath which seemed to have come from flywheel housing/rear crank seal area. Now seriously unimpressed, I took the engine out and apart. Found three things I didn't like.

1. The flywheel housing was not sealed the way I'd do it (or the manual said) and the sealant had not stuck to the main bearing cap at all.

Picture of the flywheel housing.

2. No oil pump gasket

3. Some of the piston/bore clearances were way over spec.

Sent a mail asking about the 3 points, to which the reply was:-

There couldn't an oil leak since the engine had never run (but it had been cranking over endlessly while I fruitlessly searched for compression).

No oil pump gasket was their procedure (fair enough but of the limited number of engine builders I asked, all used a gasket or sealant. Nobody used nothing)

Didn't really say anything about the piston clearance except to say that different manufacturer had different clearances (yeah but what about my Pistons)

Also, all the grit must have been from my fitting of the head not casting grit (suppose I don't have any proof, other than a £140 bill for stripping and cleaning the head)

And finally (my favourite bit) they didn't authorise me stripping my engine so couldn't take responsibility but would advise me on clearances and torque settings. My subsequent email requesting clearances unfortunately coincided with a failure of their computer system which meant that they could no longer reply to my emails (I guess that's the reason - can't think of anything else it could be)

I took the block and Pistons to hamlins to check my measurements. They said the bores were good but the Pistons varied so much the the clearances were over spec so unless each bore was individually matched to the piston, it was never going to be any good. They also said the Pistons were the most badly manufactured (cheap) they had ever seen. I guess that means britpart which is not really what I expected from a top(ish) priced engine but if cheap Pistons must be used, they could have at bothered to get four that matched each other.

Obviously I'm really disappointed and feel completely ripped off however I appreciate that everyone makes mistakes but it's how you manage the mistakes that makes the difference. I thought paying nearly top whack would mean some kind of guarantee of quality but actually it just means I'm a mug. Not all their engines can be like this otherwise they couldn't stay in business but you get a duff one, you're on your own.

So it's rebuild time for me, look for another thread where the engine rises from the ashes like an erection from baggy underpants.

Just off for a quick cry (again)

A series2a bitsa with 2.5na motor. Last August it seemed even slower than usual and a compression test made me decide to get a recon head from (let's call them) A Company of Reconditioners of Landrover. All seemed OK with professional looking masking tape over the ports.

Before putting the head on, a quick look at the bores revealed no wear lips but 2 Pistons had a good few mm of side movement and one of the liners had dropped by about 2mm. After a quick panic and deciding I didn't have the time or confidence to rebuild it, I got a 3/4 exchange engine from the afore mentioned company.

I nailed on the head, put it back in the vehicle but couldn't start it. Lots of headscratching and checking injectors, eventually found no compression. Checked with the company who said i must have timed it wrong so whipped the timing cover and found the cam sprocket was touching the back of the timing cover because the thrust plate was missing. So I removed it sent it back for the thrust plate and lost compression.

Picture with camshaft sticking out.

Returned after a week or so, seemed to have compression when turning it over on the pallet with a spanner so I put it back in the vehicle. Couldn't start it, checked compression straight away-low or none. Checking with a leak down tester showed leaking valves. The recon company said just send it back and they would start it. I wasn't entirely happy as I wanted it soon as possible, so I took the head off and gave it to a company called hamlins in bridgewater who said it was a new casting that hadn't been cleaned properly and the grit was intermittently falling off and blocking the valves. They basically just checked, cleaned it and lapped the valves.

Went to put the head on and noticed a lot of oil underneath which seemed to have come from flywheel housing/rear crank seal area. Now seriously unimpressed, I took the engine out and apart. Found three things I didn't like.

1. The flywheel housing was not sealed the way I'd do it (or the manual said) and the sealant had not stuck to the main bearing cap at all.

Picture of the flywheel housing.

2. No oil pump gasket

3. Some of the piston/bore clearances were way over spec.

Sent a mail asking about the 3 points, to which the reply was:-

There couldn't an oil leak since the engine had never run (but it had been cranking over endlessly while I fruitlessly searched for compression).

No oil pump gasket was their procedure (fair enough but of the limited number of engine builders I asked, all used a gasket or sealant. Nobody used nothing)

Didn't really say anything about the piston clearance except to say that different manufacturer had different clearances (yeah but what about my Pistons)

Also, all the grit must have been from my fitting of the head not casting grit (suppose I don't have any proof, other than a £140 bill for stripping and cleaning the head)

And finally (my favourite bit) they didn't authorise me stripping my engine so couldn't take responsibility but would advise me on clearances and torque settings. My subsequent email requesting clearances unfortunately coincided with a failure of their computer system which meant that they could no longer reply to my emails (I guess that's the reason - can't think of anything else it could be)

I took the block and Pistons to hamlins to check my measurements. They said the bores were good but the Pistons varied so much the the clearances were over spec so unless each bore was individually matched to the piston, it was never going to be any good. They also said the Pistons were the most badly manufactured (cheap) they had ever seen. I guess that means britpart which is not really what I expected from a top(ish) priced engine but if cheap Pistons must be used, they could have at bothered to get four that matched each other.

Obviously I'm really disappointed and feel completely ripped off however I appreciate that everyone makes mistakes but it's how you manage the mistakes that makes the difference. I thought paying nearly top whack would mean some kind of guarantee of quality but actually it just means I'm a mug. Not all their engines can be like this otherwise they couldn't stay in business but you get a duff one, you're on your own.

So it's rebuild time for me, look for another thread where the engine rises from the ashes like an erection from baggy underpants.

Just off for a quick cry (again)

Last edited: