bankz5152

Well-Known Member

- Posts

- 9,146

- Location

- South London/North Kent

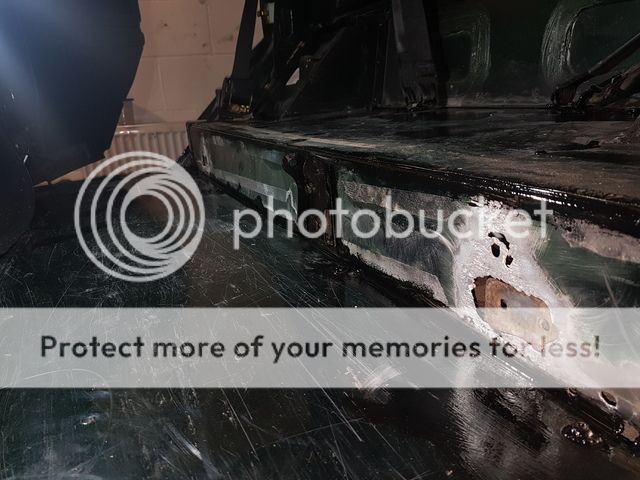

Thought id get cracking on the soundproofing today, nice and easy i said. How wrong i was...

Found a hole, many holes actually, ali corrosion, how do I fix this? Cut it out and rivet a panel on top?

Found a hole, many holes actually, ali corrosion, how do I fix this? Cut it out and rivet a panel on top?