DIFFLOCK66

Well-Known Member

- Posts

- 3,249

- Location

- Chipping, Lancashire

Haynes says to torque these guys to 360 lb/ft. Over 3 times tighter than a wheel nut! Why so astronomically high a value?  Most Landy engines don't get close to outputting that amount of torque (Doc Evil's big block V8 excepted) :wtf:

Most Landy engines don't get close to outputting that amount of torque (Doc Evil's big block V8 excepted) :wtf:

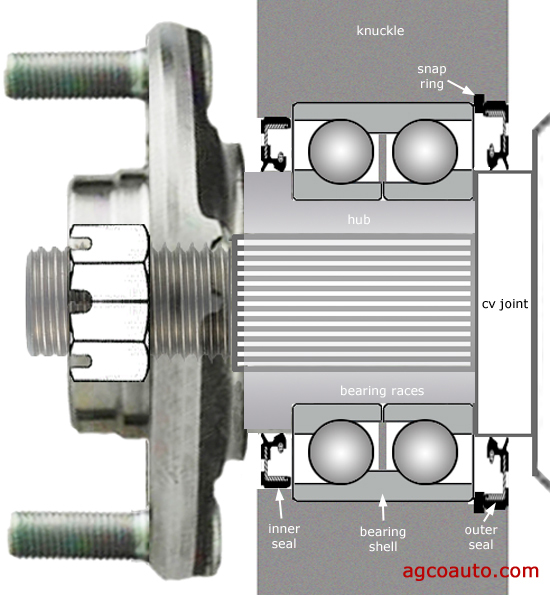

Looking at the install, all the nut does is secure the halfshaft to the inner (rotating) part of the hub. The halfshaft uses splines to transmit the drive to the hub, not friction!! The nut will not stop the halfshaft and wheel from parting company with the axle - if the inner hub separates from the outer, static part then that shaft's on its way out. Only the brake caliper would hinder the process

The hub assembly is held on the axle by 4 relatively beefy bolts which only require 74 lb/ft each. If they snap, it's game over again

Looking at the install, all the nut does is secure the halfshaft to the inner (rotating) part of the hub. The halfshaft uses splines to transmit the drive to the hub, not friction!! The nut will not stop the halfshaft and wheel from parting company with the axle - if the inner hub separates from the outer, static part then that shaft's on its way out. Only the brake caliper would hinder the process

The hub assembly is held on the axle by 4 relatively beefy bolts which only require 74 lb/ft each. If they snap, it's game over again