nrgserv

Well-Known Member

- Posts

- 4,208

- Location

- shipley, west yorks.

todays tinkering was with the c pillar repairs and the inadvertent manufacture of a couple of door hinge bolts.

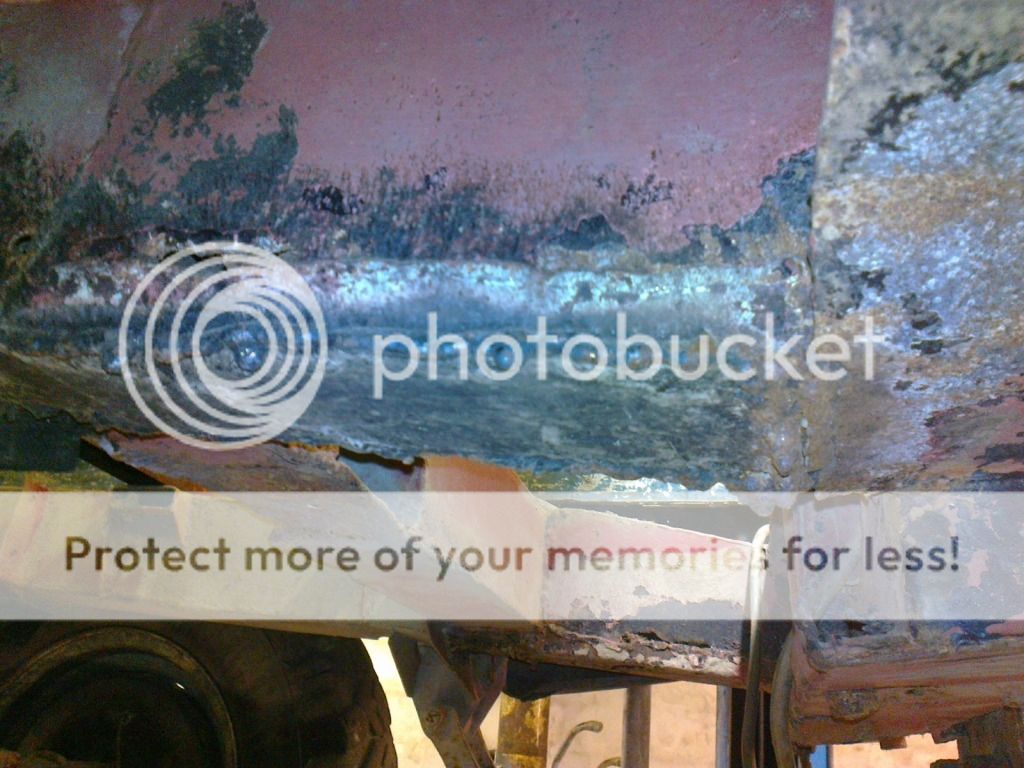

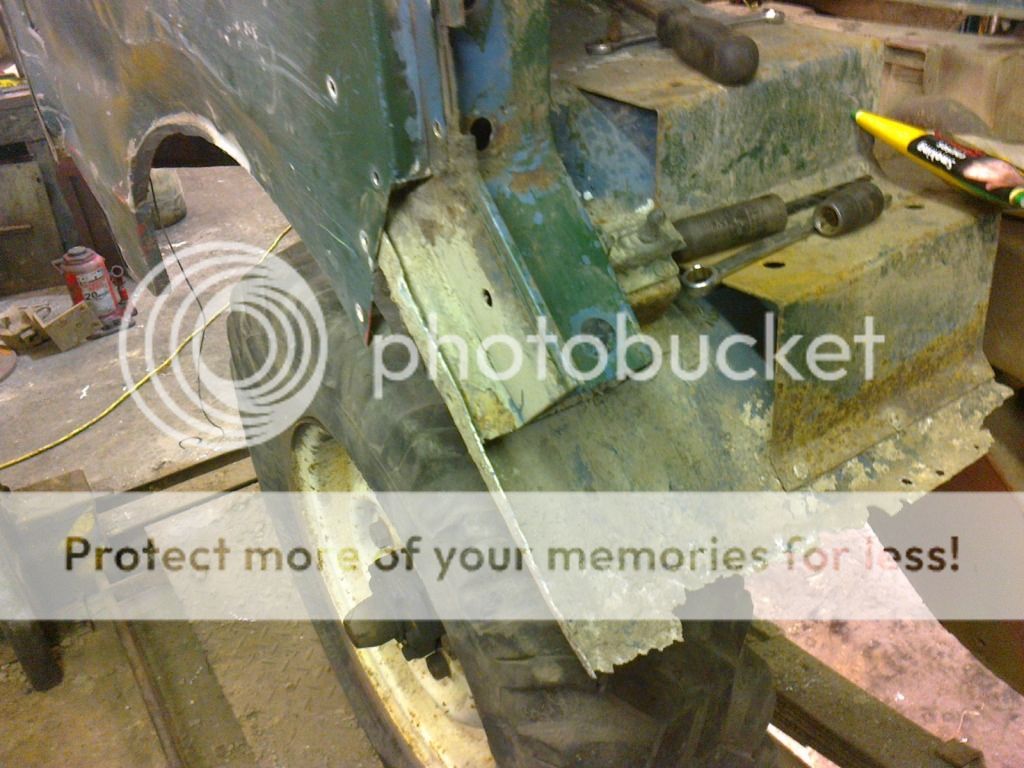

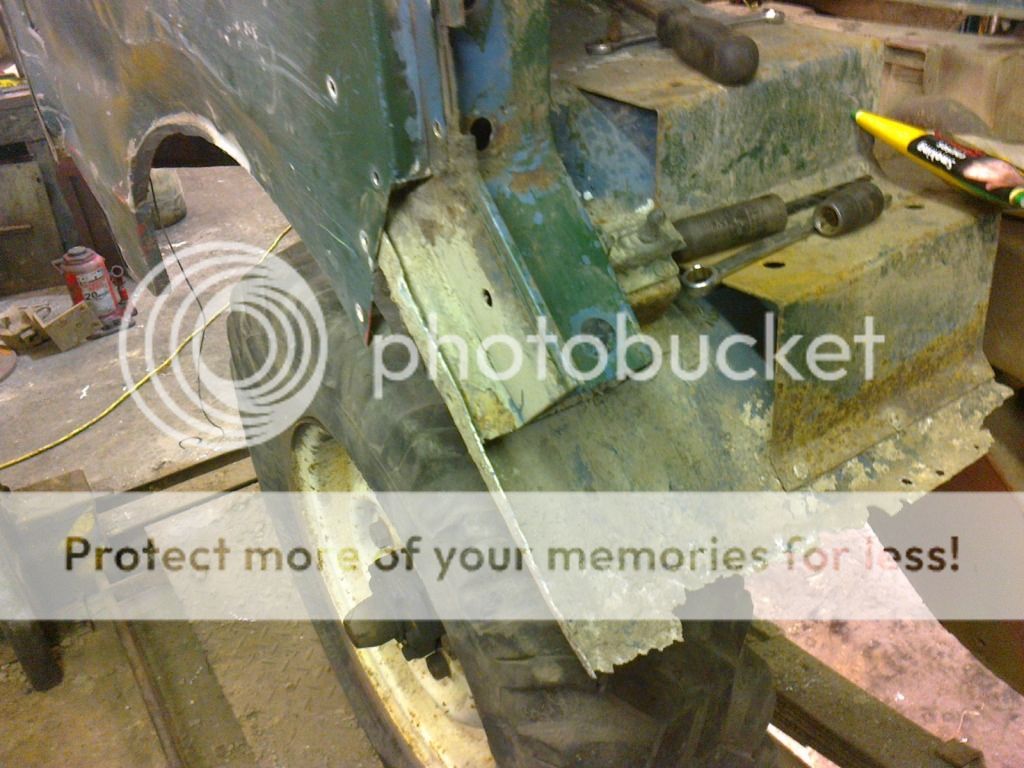

first off was cut the cak off the bottom of the old c pillar

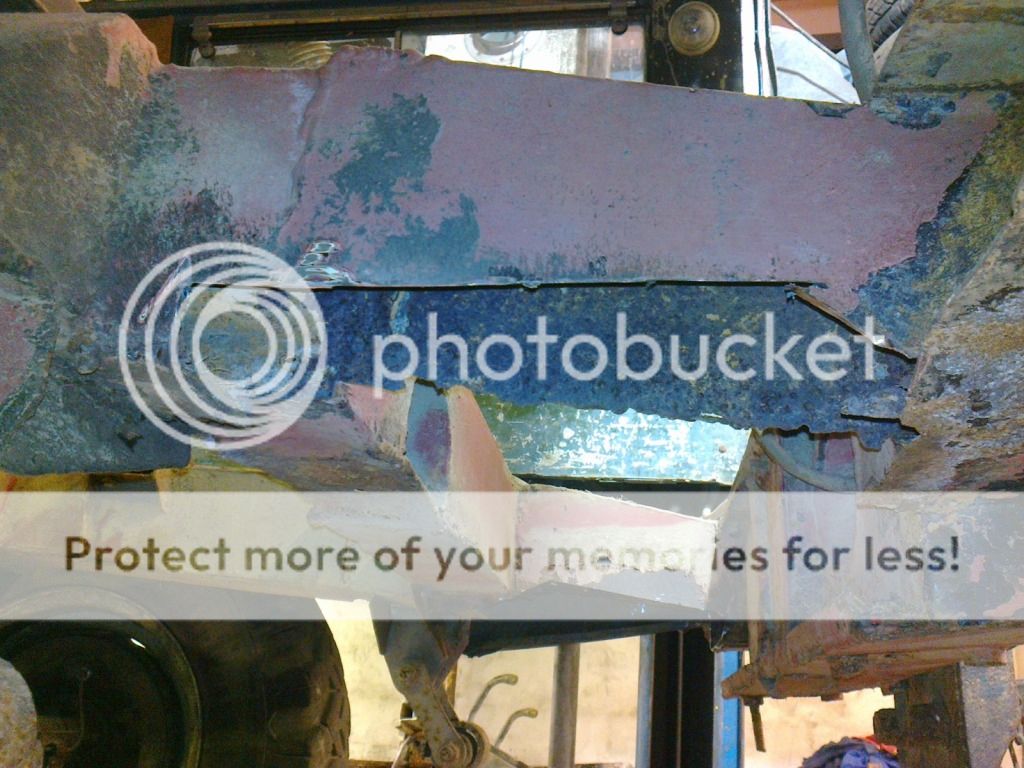

after a bit of codgitation, head scratching and a smoky, a plan was divised.

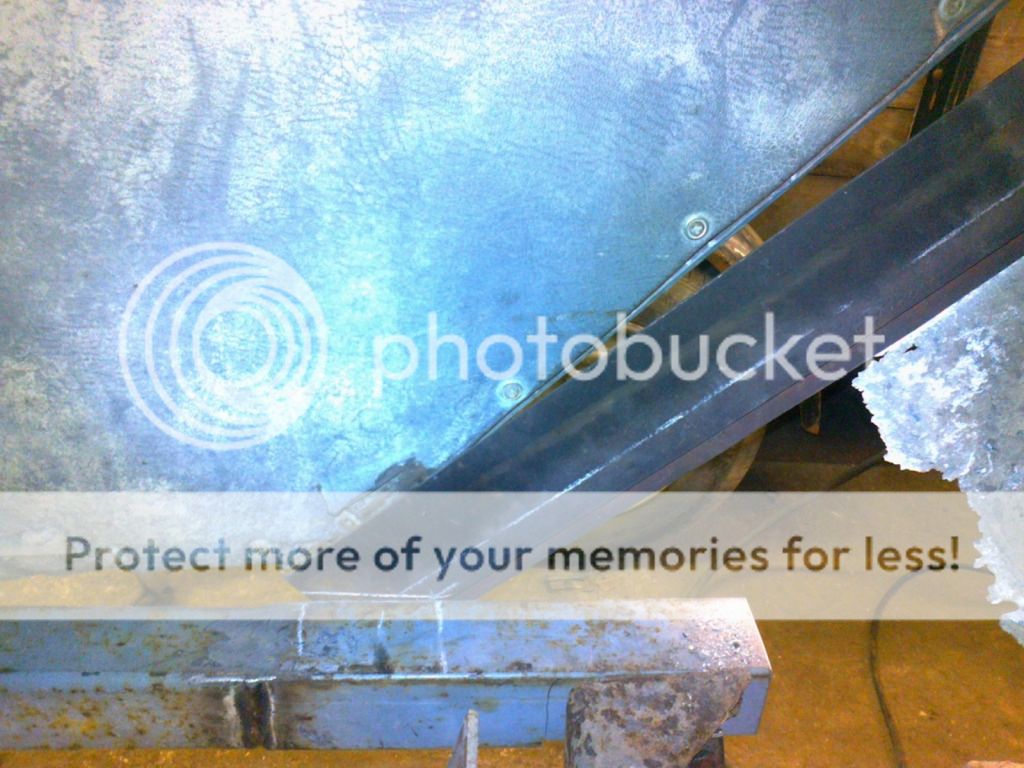

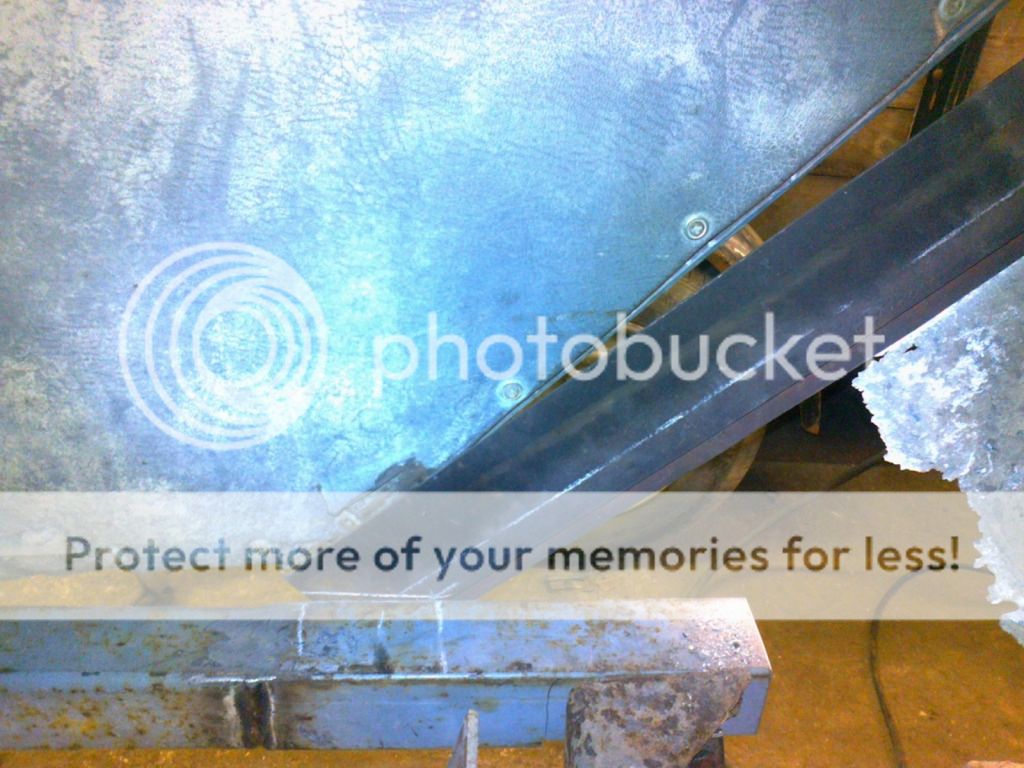

due to the bender not being able to put a return bend on tight enough, the return was welded from the inside

then the outside was ground off giving a radius similar to the old c pillar

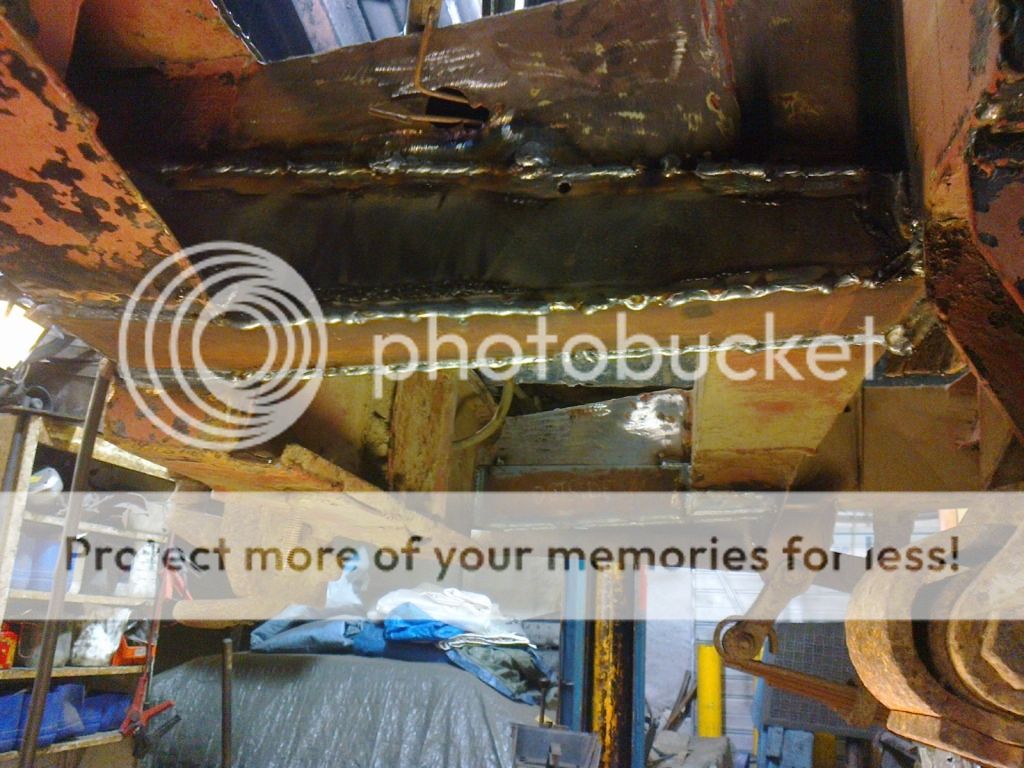

this lot was then trial fitted to ensure stuff lined up.

all appeared good so a bit more than tacked in.....

then thought it might be a good idea to check the door fits the door hole before any more welding.

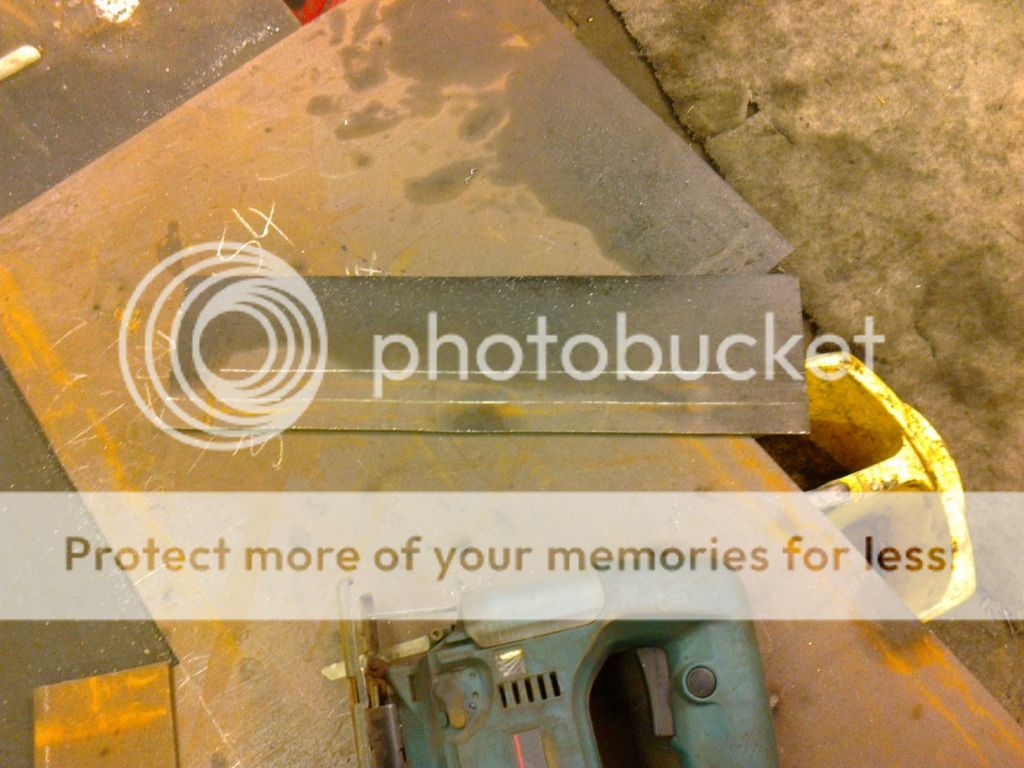

had to whip up a couple of hinge bolts as the ones i bought were too short

the lathe shot's just for johnny!

hmmm.... got it wrong somewhere

so an impromtu alteration

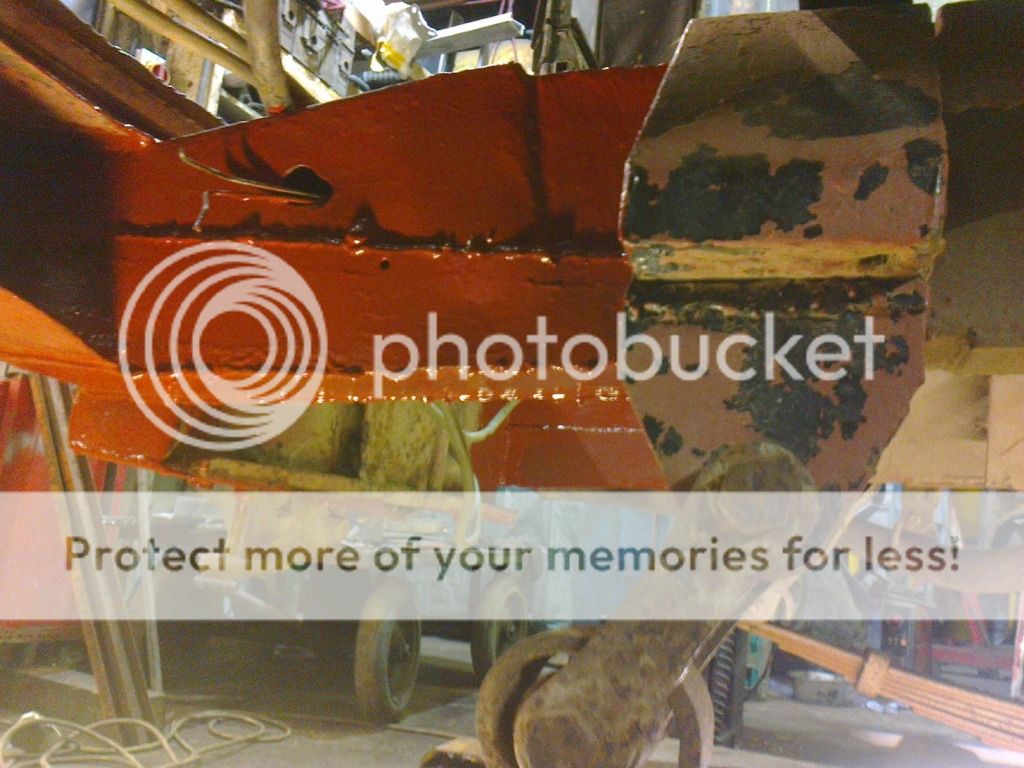

once the angle looked good, even with the door shut, fabrication of the box section for the c pillar ensued

all was replaced, a couple of rivits popped in the top end and the bottom end welded in.

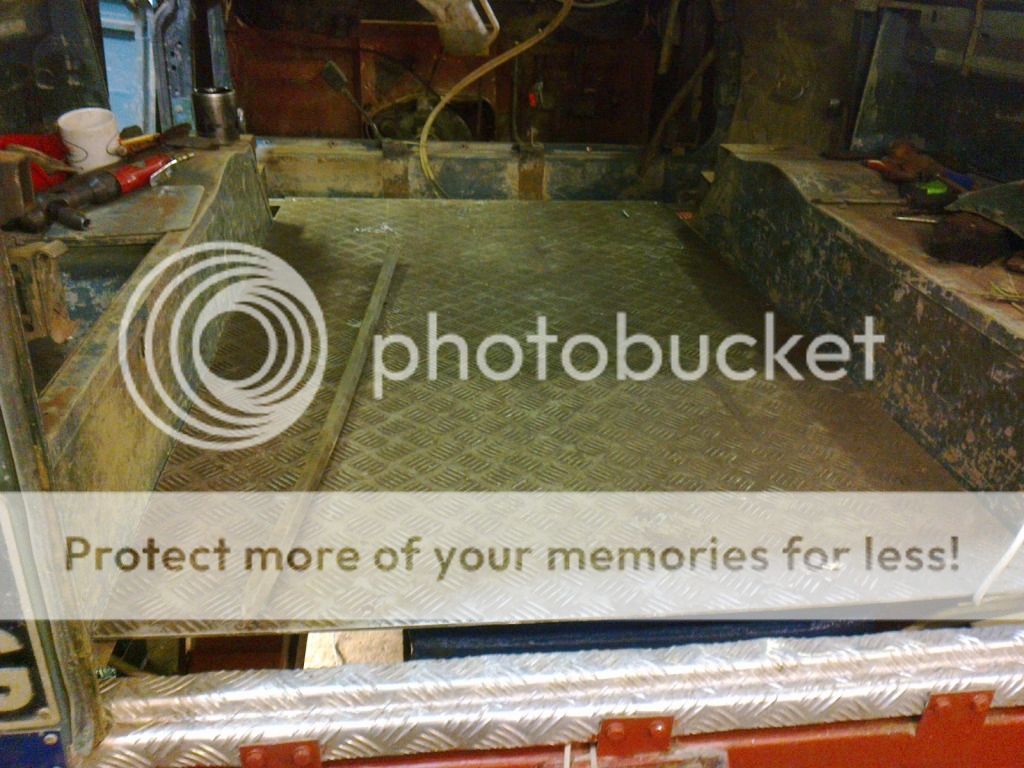

tomorrow will probably be the floor for the middle mounts, and the rear floor if time allows.

and finally, the rubber tube.

the dog must have been a bit bored today, as i seemed to spend half the time throwing the tube for him. hopefully tomorrow being saturday there might be a few other folks down to throw bushes and tube. however, that also means more coffee fags and talkin!

first off was cut the cak off the bottom of the old c pillar

after a bit of codgitation, head scratching and a smoky, a plan was divised.

due to the bender not being able to put a return bend on tight enough, the return was welded from the inside

then the outside was ground off giving a radius similar to the old c pillar

this lot was then trial fitted to ensure stuff lined up.

all appeared good so a bit more than tacked in.....

then thought it might be a good idea to check the door fits the door hole before any more welding.

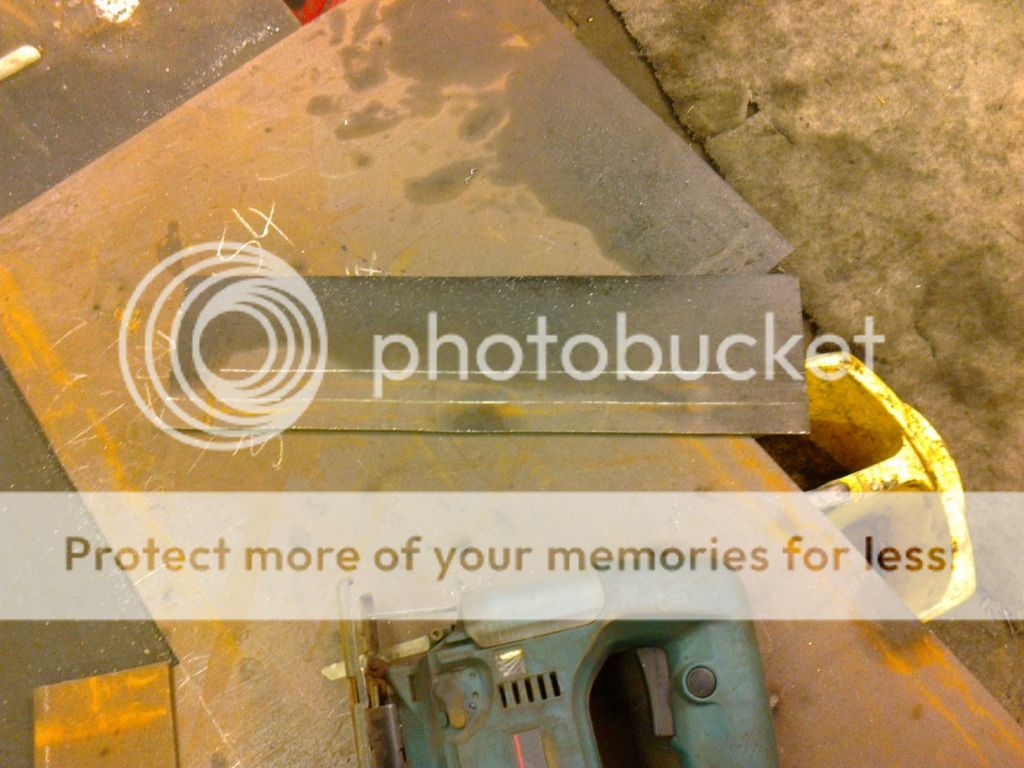

had to whip up a couple of hinge bolts as the ones i bought were too short

the lathe shot's just for johnny!

hmmm.... got it wrong somewhere

so an impromtu alteration

once the angle looked good, even with the door shut, fabrication of the box section for the c pillar ensued

all was replaced, a couple of rivits popped in the top end and the bottom end welded in.

tomorrow will probably be the floor for the middle mounts, and the rear floor if time allows.

and finally, the rubber tube.

the dog must have been a bit bored today, as i seemed to spend half the time throwing the tube for him. hopefully tomorrow being saturday there might be a few other folks down to throw bushes and tube. however, that also means more coffee fags and talkin!