Having embarked on a rebuild of my 200 TDI (Defender) engine, it would seem the final piece of the puzzle will be the manifold, the rebuild is complete, but it looks like the current manifold is quite restrictive, not particularly good at retaining heat and also the ports don't seem to align particularly well. I know that Fourby do a twin inlet manifold, but this for a 300 TDI, but this will mean relocating my turbo and other engine bay reconfiguration, which isn't something I want to do. Does anyone now of any other options or custom options for a 200 TDI? I have put out some feelers with a couple of fabricators, but am interested if anyone else has successfully done this before?

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Custom 200TDI Manifold

- Thread starter Nardo90

- Start date

This site contains affiliate links for which LandyZone may be compensated if you make a purchase.

steve2286w

Well-Known Member

- Posts

- 5,083

- Location

- monkeyangerland

https://www.landyzone.co.uk/land-rover/ricks-200tdi-tuning-guide.254178/

Have you seen this

Turners also modify heads

Have you seen this

Turners also modify heads

This is the Fourby Manifold

https://fourby.co.uk/Tdi-Twin-Inlet-Performance-Manifold

https://fourby.co.uk/Tdi-Twin-Inlet-Performance-Manifold

steve2286w

Well-Known Member

- Posts

- 5,083

- Location

- monkeyangerland

Sounds nice but apart from

“When you supply each cylinder with the same precise dose of air, at the same pressure, then you harmonise the torque given to the crankshaft for every power stroke.”

is there any other measureable benefit claimed

“When you supply each cylinder with the same precise dose of air, at the same pressure, then you harmonise the torque given to the crankshaft for every power stroke.”

is there any other measureable benefit claimed

Not sure, I was working of the basis the air would flow freer and potentially I could get it ceramic coated, primarily keeping the heat in the manifold and out of the engine bay. Keeping the temps down has got to be a winner, should create some minor performance gains, but if I can do the down pipe at the same time, I should help managing the engine bay temp and make the turbo more effective.

rob1miles

Well-Known Member

- Posts

- 3,565

- Location

- Slough and Bath

I'm confused, are you looking at the inlet or exhaust manifold? That twin branch inlet looks nice but I doubt it does anything. The turbo is feeding the air into the plenum at positive pressure so I don't think the flow part matters in the same way it does with a naturally aspirated inlet. There's some test on the web somethere with ports being moved out of line to see what difference it makes, about 1/4" off makes hardly any, even the guys doing it were suprised. If its exhaust then its either pay shed loads or make your own. I need a very simple one for my Perkins and I'm going to fab it myself out of mild steel - parts are only about £30 buying ready made bends. If its a success and I get the fit right I'll probably re-make the same thing in stainless but that gives me time to improve my welding!

I would agree with rob on the inlet manifold, and would concentrate your efforts on the ex manifold, but even then I cannot see it making a huge difference, must be one of them things, the law of deminishing returns.

Iirc allard used to do a vgt for the 200 and 300 models, was expensive circa 1k ish, edit its 1.5k.

http://www.allardturbosport.co.uk/index.php?page=Defender-and-Discovery-200-300-TDI

I am sure there is an old thread where the guy fitted a vgt off a vag motor onto a custom 4 branch ex manifold, might be worth a search, he certainly did a lot of research and effort to get it right.

Iirc allard used to do a vgt for the 200 and 300 models, was expensive circa 1k ish, edit its 1.5k.

http://www.allardturbosport.co.uk/index.php?page=Defender-and-Discovery-200-300-TDI

I am sure there is an old thread where the guy fitted a vgt off a vag motor onto a custom 4 branch ex manifold, might be worth a search, he certainly did a lot of research and effort to get it right.

Zed.

Well-Known Member

- Posts

- 1,842

- Location

- Deepest Bandit country (Wales)

is there any other measureable benefit claimed

looks good & gets instagram likes??

That twin branch inlet looks nice but I doubt it does anything. The turbo is feeding the air into the plenum at positive pressure so I don't think the flow part matters in the same way it does with a naturally aspirated inlet. There's some test on the web somethere with ports being moved out of line to see what difference it makes, about 1/4" off makes hardly any, even the guys doing it were suprised.

look up 'twin plenium' manifolds

https://www.bufkinengineering.com/intake manifolds.htm

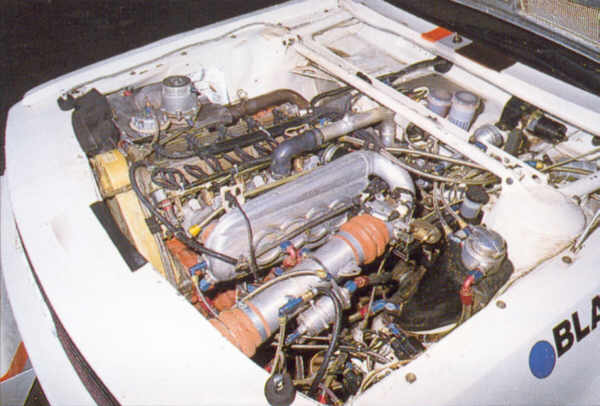

audi played with manifolds on the Quatro group B rallycars (old tec now!) but that'll give you an idea

if you're getting the hot-glue out then maybe this is a direction to look in?

Rich.

Zed.

Well-Known Member

- Posts

- 1,842

- Location

- Deepest Bandit country (Wales)

Similar threads

- Replies

- 0

- Views

- 419