Rugby and Land Rovers

Member

- Posts

- 15

- Location

- West Sussex

Hi all,

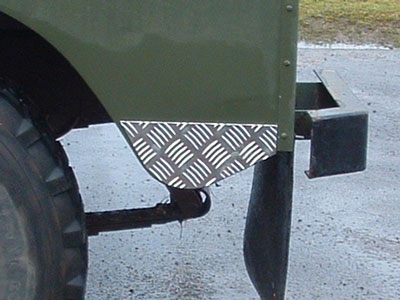

What are your views on what I should do with this (see photo below)?

As ever, thanks for your help.

What are your views on what I should do with this (see photo below)?

- Is it something a normal garage would be able to fix (I lack the tools/knowhow)?

- Or would it be necessary to use a Land Rover specialist like Gumtree 4x4 (my nearest one)?

- Or is it a case of sourcing a new panel?

As ever, thanks for your help.