OscarBoy

Member

- Posts

- 16

- Location

- Southampton

Hi All,

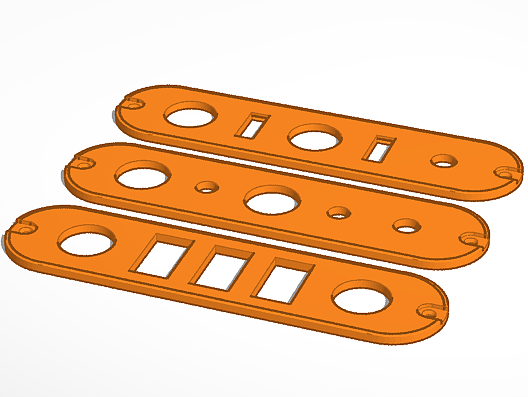

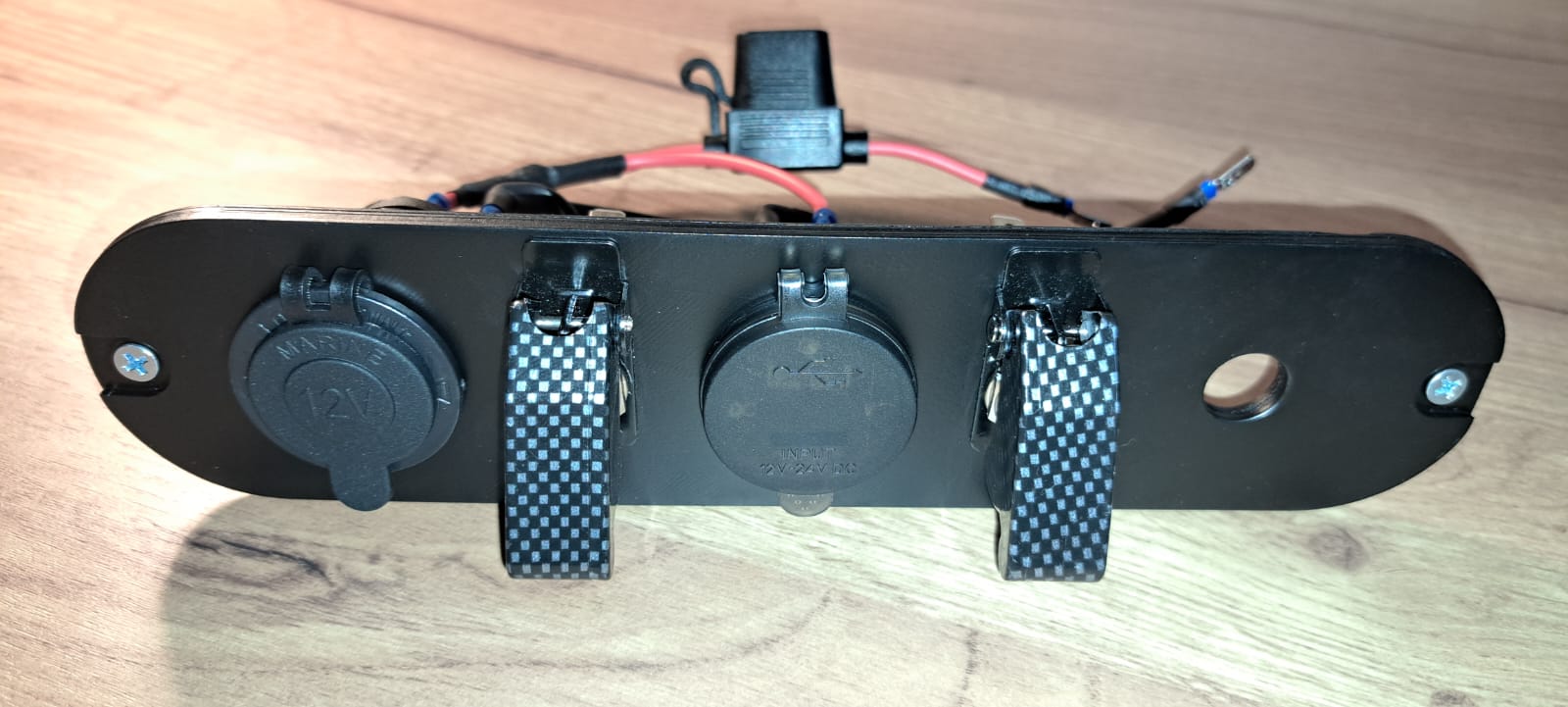

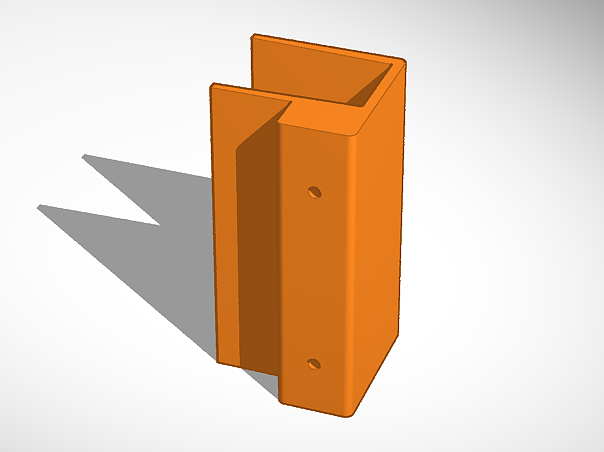

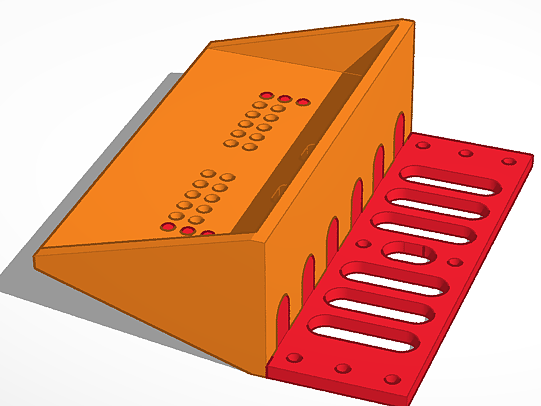

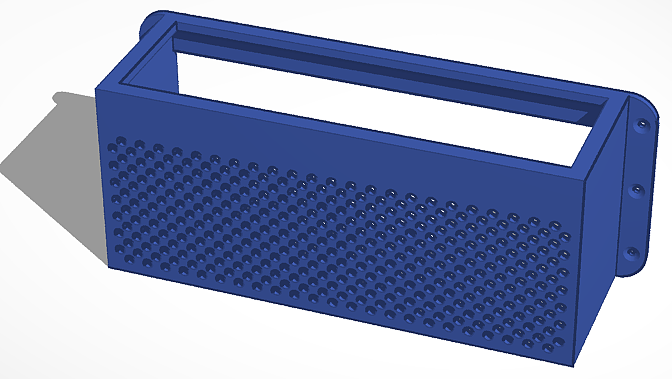

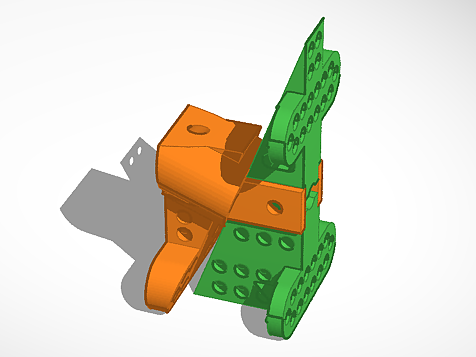

This is a project I did back in April 2021. The project was to design and print a dashboard binnacle for an android head unit installation in my 1998 Defender (pre-TD5).

This is the 1st revision, so I have only printed it in draft for test fitment. As a result, the finish isn't perfect, but as a proof of concept, it actually came out pretty good.

I installed a generic 7" android unit from eBay (since replaced with another from Amazon with more internal RAM and storage space). In the design, I have space for a 25mm NFC tag behind the front facia to automate connectivity from the phone to the head unit.

I am thinking of revisiting this project to add some more features. Perhaps try a new design with a wider front plate to accommodate some space for switches.

If there is any interest in this then I'll post some updates as it progresses.

If you want to print this yourself you can download the files from Thingiverse.

https://www.thingiverse.com/thing:5856588

This is a project I did back in April 2021. The project was to design and print a dashboard binnacle for an android head unit installation in my 1998 Defender (pre-TD5).

This is the 1st revision, so I have only printed it in draft for test fitment. As a result, the finish isn't perfect, but as a proof of concept, it actually came out pretty good.

I installed a generic 7" android unit from eBay (since replaced with another from Amazon with more internal RAM and storage space). In the design, I have space for a 25mm NFC tag behind the front facia to automate connectivity from the phone to the head unit.

I am thinking of revisiting this project to add some more features. Perhaps try a new design with a wider front plate to accommodate some space for switches.

If there is any interest in this then I'll post some updates as it progresses.

If you want to print this yourself you can download the files from Thingiverse.

https://www.thingiverse.com/thing:5856588