Alfdud

New Member

- Posts

- 9

- Location

- Winchester

Hi,

After a bit of advice if you would be so kind!

Im concious i have slipped into ramble mode here (sign of my passion in the project i took on!) If you are easily bored, skip to the bottom for a TLDR.

I am very keen to understand the cause of this failure to ensure i can mitigate it from happening again in the future and prevent any significant damage.

I think i have been very fortunate with this one, considering what could have happened!

I am a complete novice when it comes to complex mechanical jobs, previous most complex task on the landy was cutting out the fusable links and changing the rear wiper motor! However i am keen to learn, like getting hands on, and have a logical brain so thought i would give the problem a go myself and see what i could find.

I bought a haynes manual, downloaded the Landy workshop manual, bought a torque wrench, found some locktite nut locker, forgot to get gloves, and got very oiley.

I had a horrible metal on metal tinging noise coming from the rear end when the drive train was under heavy load (Gear change/pulling away), i "thought" i had narrowed it down to the rear diff causing the noise, I had a google, watched some youtube vids, ignored the haynes manual which suggested diff rebuilds were not a DIY job, and proceeded to take it off and take it to peices!

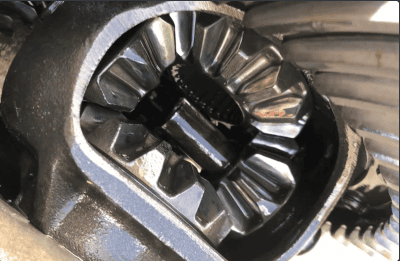

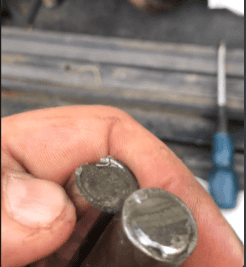

I thought i had struck gold, i found the Diff Cross shaft completely sheared just as it protrudes from one of the Center Gears.

I identified that i would need to remove the crown wheel to get the cross shaft out, so i did some homework and worked out what i needed to do to ensure i put it all back together properly. Bought myself a dial gauge, checked on the required backlash etc......

Bought a new cross shaft for 6 quid, put it all back together properly, and it worked!

However the noise was still there! I subsequently found that it was the UJ causing the noise, i took it off and the UJ was dry as a bone and rotten! Again more reading, instead of just replacing UJ's i bought a new wide angle prop to account for my 2" Lift.

TLDR Bit - The real question i want answered is as follows:

What would have caused the center shaft to shear like it has?

Thinking about its purpose logically, its job is not to be an axle of sorts for the 2 gears that revolve around it as there would be a bearing between the shaft and the gear, i assume its job is to prevent any sideways rotation in those gears?

In which case, A clean shear just as it exits one of the gears would logically suggest that it is one of two things:

I have no idea how long it had been like that, and i feel very fortunate that it did not obliterate the diff or TB or worse and want to make sure i udnerstand why it failed to prevent her from getting hurt again in the future!

P.S Sorry for wordy post. I like my detail Concious not everyone else does, if you stuck with it, thank you.

Concious not everyone else does, if you stuck with it, thank you.

Here are pics of the damaged shaft:

After a bit of advice if you would be so kind!

Im concious i have slipped into ramble mode here (sign of my passion in the project i took on!) If you are easily bored, skip to the bottom for a TLDR.

I am very keen to understand the cause of this failure to ensure i can mitigate it from happening again in the future and prevent any significant damage.

I think i have been very fortunate with this one, considering what could have happened!

I am a complete novice when it comes to complex mechanical jobs, previous most complex task on the landy was cutting out the fusable links and changing the rear wiper motor! However i am keen to learn, like getting hands on, and have a logical brain so thought i would give the problem a go myself and see what i could find.

I bought a haynes manual, downloaded the Landy workshop manual, bought a torque wrench, found some locktite nut locker, forgot to get gloves, and got very oiley.

I had a horrible metal on metal tinging noise coming from the rear end when the drive train was under heavy load (Gear change/pulling away), i "thought" i had narrowed it down to the rear diff causing the noise, I had a google, watched some youtube vids, ignored the haynes manual which suggested diff rebuilds were not a DIY job, and proceeded to take it off and take it to peices!

I thought i had struck gold, i found the Diff Cross shaft completely sheared just as it protrudes from one of the Center Gears.

I identified that i would need to remove the crown wheel to get the cross shaft out, so i did some homework and worked out what i needed to do to ensure i put it all back together properly. Bought myself a dial gauge, checked on the required backlash etc......

Bought a new cross shaft for 6 quid, put it all back together properly, and it worked!

However the noise was still there! I subsequently found that it was the UJ causing the noise, i took it off and the UJ was dry as a bone and rotten! Again more reading, instead of just replacing UJ's i bought a new wide angle prop to account for my 2" Lift.

TLDR Bit - The real question i want answered is as follows:

What would have caused the center shaft to shear like it has?

Thinking about its purpose logically, its job is not to be an axle of sorts for the 2 gears that revolve around it as there would be a bearing between the shaft and the gear, i assume its job is to prevent any sideways rotation in those gears?

In which case, A clean shear just as it exits one of the gears would logically suggest that it is one of two things:

- Either there was a significant force applied which rotated the gearing and the shaft did its job and prevent the rotation but sheared under pressure.

- Dodgy shaft and weakness which over time was bound to go?

I have no idea how long it had been like that, and i feel very fortunate that it did not obliterate the diff or TB or worse and want to make sure i udnerstand why it failed to prevent her from getting hurt again in the future!

P.S Sorry for wordy post. I like my detail

Here are pics of the damaged shaft: