You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Steve's unexpected Series 3 rebuild.

- Thread starter LincolnSteve

- Start date

This site contains affiliate links for which LandyZone may be compensated if you make a purchase.

LincolnSteve

Well-Known Member

- Posts

- 1,224

- Location

- Lincoln

I'm beginning to think that if puraflex can't fix then it's not worth fixing.Excellent mate. You’re a puraflex man too! I found it at tool station years ago and it’s so good for seam sealing

Bobsticle

De Villes Advocaat

- Posts

- 27,632

- Location

- Manchester

An update. Thank god for that.

I’ve been pacing.

Not touched my camper for three weeks as I’ve been away. Wimmins just don’t understand that our quality time together requires me to be at my lockup…….. alone.

I’ve had to book time off in August just to catch up

I’ve been pacing.

Not touched my camper for three weeks as I’ve been away. Wimmins just don’t understand that our quality time together requires me to be at my lockup…….. alone.

I’ve had to book time off in August just to catch up

LincolnSteve

Well-Known Member

- Posts

- 1,224

- Location

- Lincoln

Time is unbelievably short isn't it? We had look at what we've got on for the next few weeks and there is something going on every weekend until the holiday then this other job is going to kick off in September and probably drag on into October by when James is back at school and starting the important GCSE year. I'm not moaning and wouldn't ever put the landy ahead of the family or home but the length of time it's taking is getting embarrassing. Plus I think the gearbox has got to come back out. Oh joy.

Bobsticle

De Villes Advocaat

- Posts

- 27,632

- Location

- Manchester

I think the important thing is taking one job at a time and chipping away at it. At least you get a feeling of progress. A general help is also being pig headed enough to battle on even after a layoff.

It’s looking fantastic Steve, keep up the good work buddy.

It’s looking fantastic Steve, keep up the good work buddy.

LincolnSteve

Well-Known Member

- Posts

- 1,224

- Location

- Lincoln

Thanks mate. As they say round this way, we just keep buggering on in steady and we'll get there.

GSF 109

Well-Known Member

- Posts

- 812

- Location

- Scotlandshire

Great attention to detail there - it’s going to look better than it did when new!The puraflex 40 sealer got another chance to do it's stuff. I'm going to try and seal as many places as I can as it goes back together. View attachment 293551

View attachment 293553

LincolnSteve

Well-Known Member

- Posts

- 1,224

- Location

- Lincoln

So here's the latest problem. I noticed a little oil on the chassis crossmember right under where the gearbox bell housing meets the back of the engine. I ran my finger round the underside and there is a leak. There's no oil in the engine so the only place it can be coming from is the oil seal round the input shaft. Now if you go back to page 15 all those years ago you'll see that I was very careful to install a good quality seal to the best of my ability. So here's the thing. I know the only thing to do is to take the box out again and have a look. The thing is I just really don't want to. I need to get this thing finished before it takes over my whole life. Plus I don't know what I could do differently that would make a difference to the quality of the seal. My fear is that there is wear on the input shaft and it just won't ever seal unless I start getting into replacing the shaft itself and that's not happening. Is that seal just another one of those leaky spots that series land rovers have always had and always will have no matter what you do. The gearbox went back in 5 years ago unbelievably and I think was filled with oil not too long after. When I discovered the leak I removed the filler plug from the side of the box and the oil immediately ran out so is in effect still 'full'. That's not much of a leak for an old landy over that length of time. But what will it be like when it's actually running. If it leaked at the same rate I could easily live with it. If it pours out and I have to take the seats/seat box/floors, etc etc out to sort it then that's worse. Let me know what you all think.

Bobsticle

De Villes Advocaat

- Posts

- 27,632

- Location

- Manchester

Ignore it. I have dozens of them successfully brushed out of mind. Every seal on my gearbox leaks, the rear diff and even the head on my rebuilt engine but I’m dammed if half a turn on the bolts is going to cost me yet another injector washer set.

LincolnSteve

Well-Known Member

- Posts

- 1,224

- Location

- Lincoln

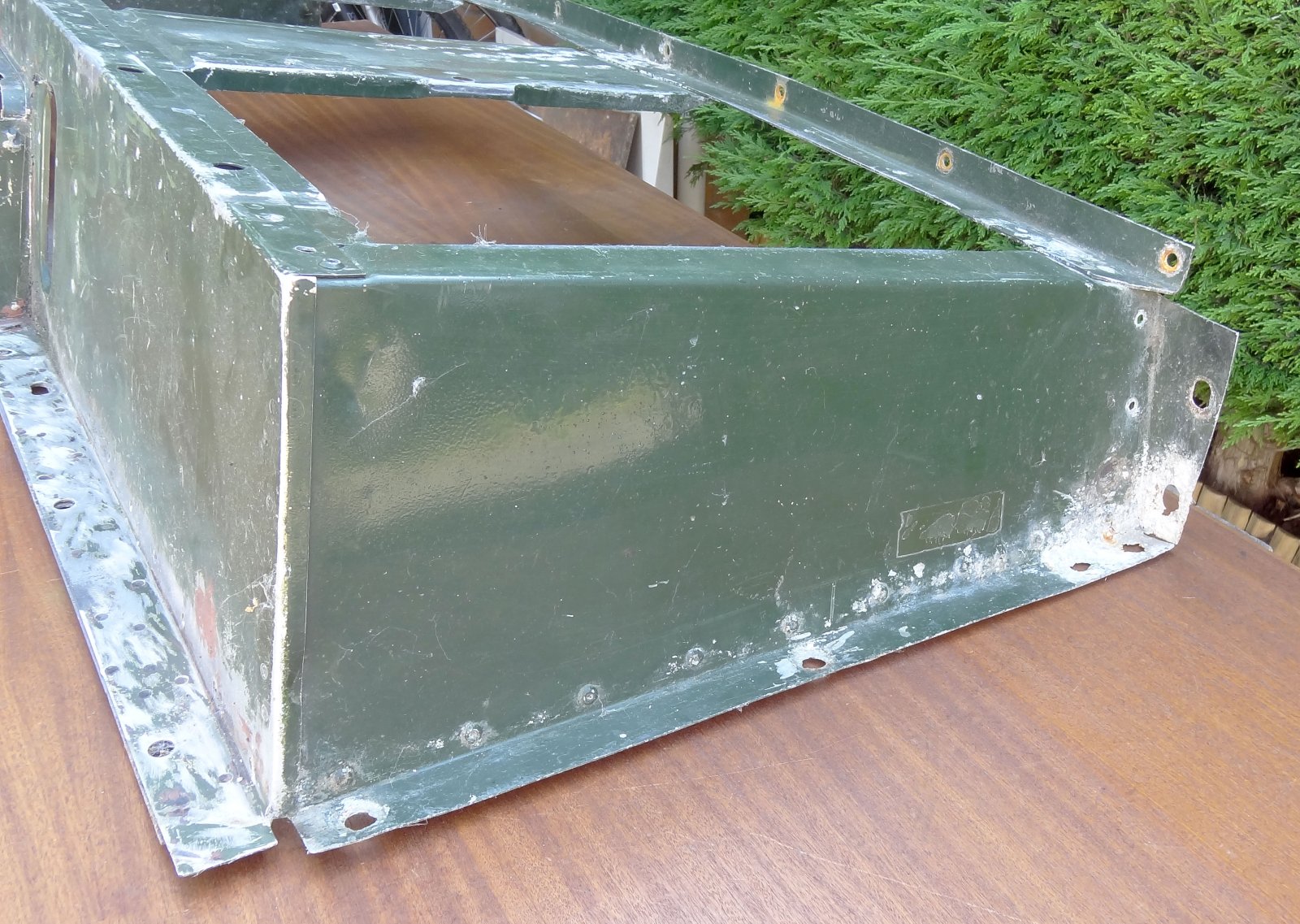

I've been having a crack at the seat box recently.

First thing was to sort out that passenger side end panel. Doesn't look too bad from here but's corroded to bits inside from being in contact with the steel of the toolbox.

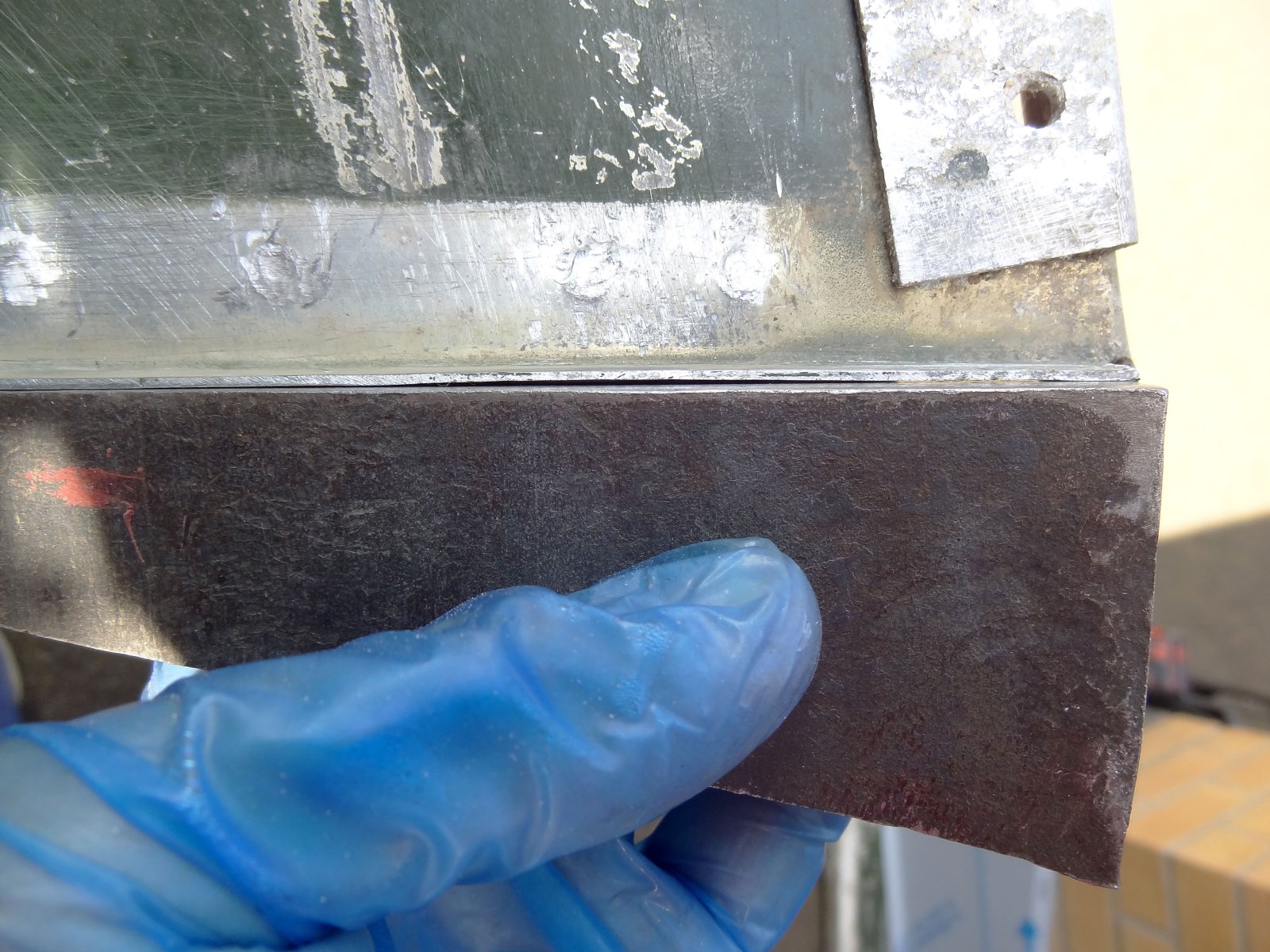

I ground away the metal from the spot welds from the inside. I wanted to leave the outside surface intact so I could decide where to position the rivets. I get frustrated when I can't keep stuff looking as it originally did but spot welding the aluminium is out of the question for me.

There wasn't too much damage to repair. This was the worst bit.

The choice with the rivets was to position them either where all the old spot welds had been or to just space them evenly. The old welds were a bit all over the place and as the rivet heads will always be very visible I went for evenly spaced. You can still see where the spot welds were but the other rivets for the tool box are done that way so that's my reasoning.

The panel is from YRM and is really good quality. Not 100% though as there are a couple of areas where the original had joggled or stepped bits that needed adding. Or am I just getting lazy.

First thing was to sort out that passenger side end panel. Doesn't look too bad from here but's corroded to bits inside from being in contact with the steel of the toolbox.

I ground away the metal from the spot welds from the inside. I wanted to leave the outside surface intact so I could decide where to position the rivets. I get frustrated when I can't keep stuff looking as it originally did but spot welding the aluminium is out of the question for me.

There wasn't too much damage to repair. This was the worst bit.

The choice with the rivets was to position them either where all the old spot welds had been or to just space them evenly. The old welds were a bit all over the place and as the rivet heads will always be very visible I went for evenly spaced. You can still see where the spot welds were but the other rivets for the tool box are done that way so that's my reasoning.

The panel is from YRM and is really good quality. Not 100% though as there are a couple of areas where the original had joggled or stepped bits that needed adding. Or am I just getting lazy.

LincolnSteve

Well-Known Member

- Posts

- 1,224

- Location

- Lincoln

Hi Bob. I'm really inclined to just leave it. You could drive yourself bonkers trying to chase every leak on these things. At the start I really thought that as long as I was careful, followed the instructions and took my time I could keep it dry. But everything that's got oil in so far is leaking. Diff drain plugs, transfer box bottom cover, steering box. Even the steering relay which I was really chuffed with myself for doing leaks a bit. It doesn't leak from the bottom though it comes out the top, against gravity. How the hell do you reckon it does that?Ignore it. I have dozens of them successfully brushed out of mind. Every seal on my gearbox leaks, the rear diff and even the head on my rebuilt engine but I’m dammed if half a turn on the bolts is going to cost me yet another injector washer set.

LincolnSteve

Well-Known Member

- Posts

- 1,224

- Location

- Lincoln

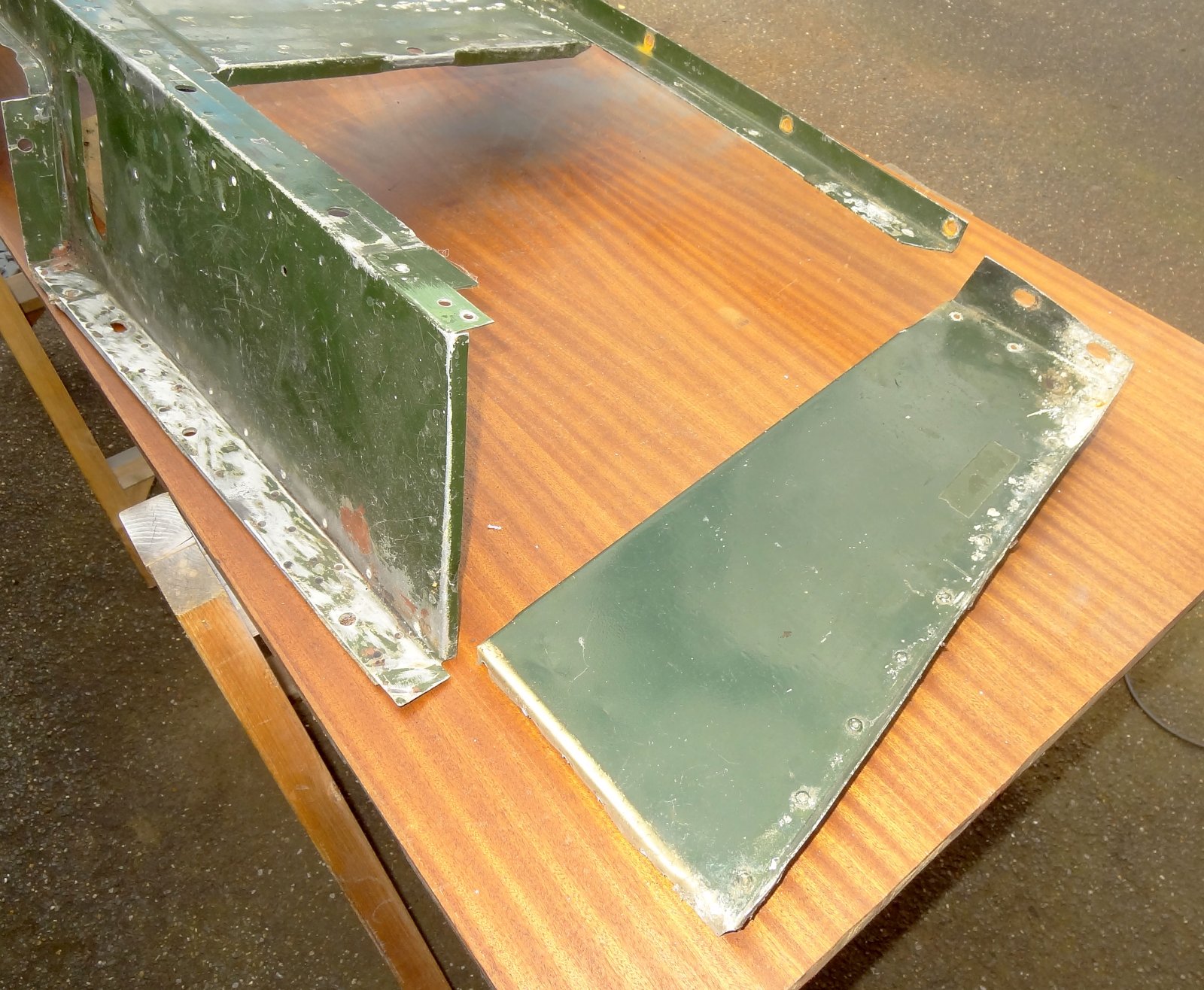

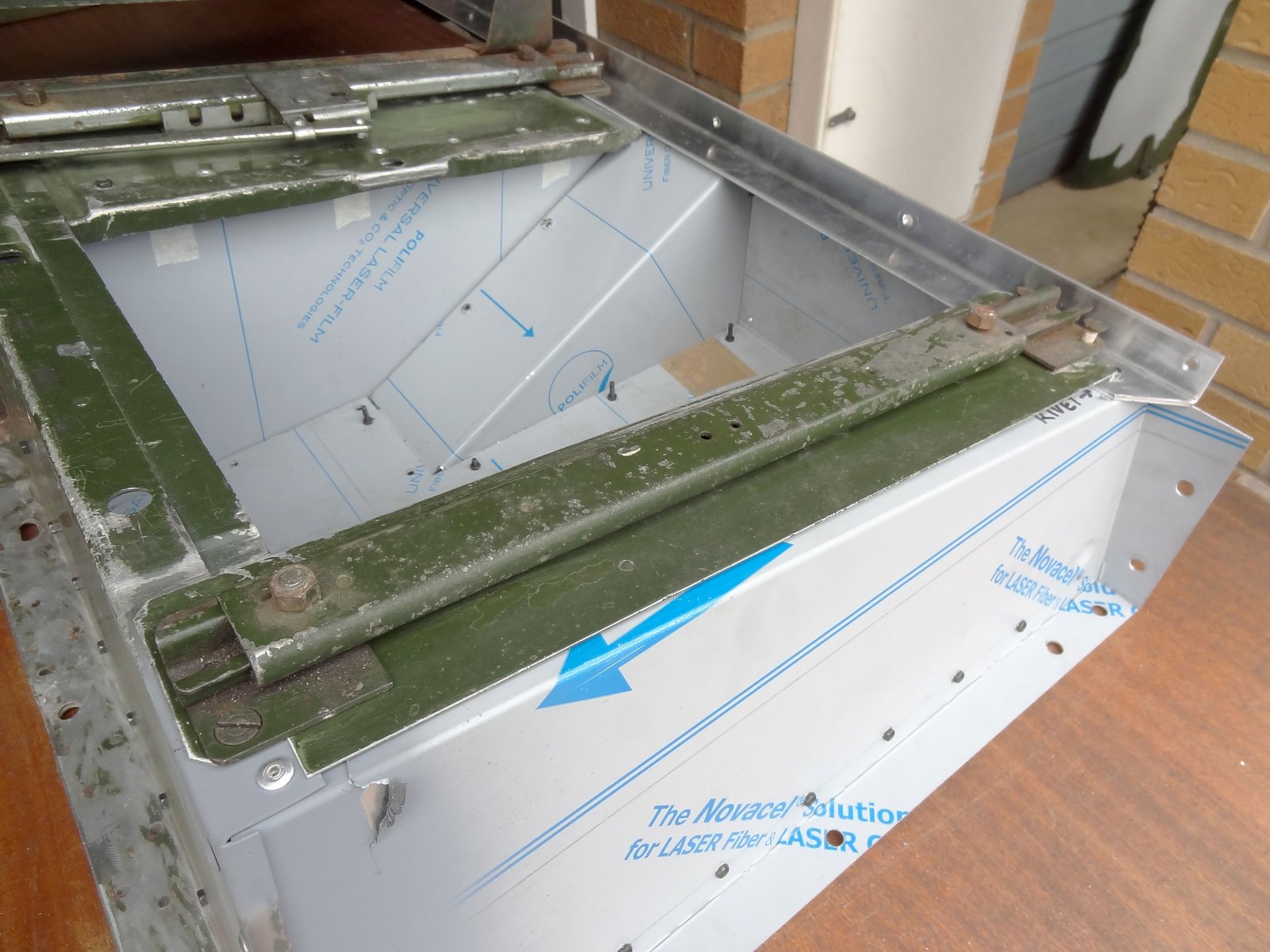

Next was the angle section on the back of the seat box that bolts it to the tub. In the past someone must have removed the seat box and then put it back in but only replaced some of the bolts. This means it got really bent out of shape and it's badly corroded.

Some rivets in this bit but a lot more spotwelds.

Old one out and a replacement from YRM again. Very accurate to the original but of course with none of the holes in so they all needed finding.

I've learned that you can't beat offering everything up on the vehicle with as many of the bits in place as possible. The times lately that some piece I thought was done and dusted has had to be changed because I forgot something else had altered.

For some reason ever since I took the seat box off I have been looking forward to getting round to fixing it. As it goes it has still been a long winded pain in the arse. That also has something to do with most of July looking like this.

With a bit more faffing we got there in the end.

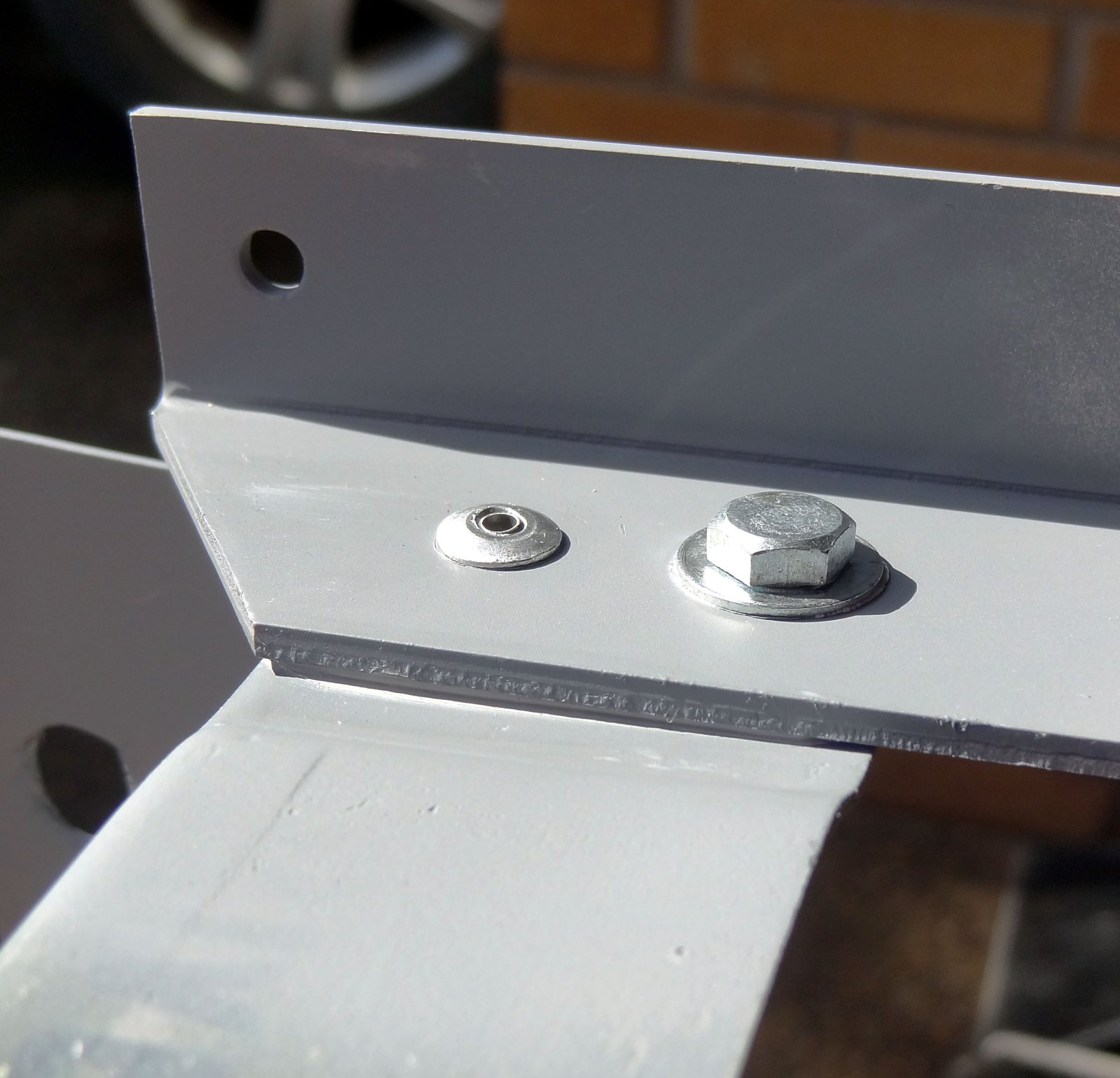

The bolts here are just temporary while the puraflex goes off. They are where the seat runners will go. The rivet on the left is as it originally was but the two on the right are there (with the puraflex) to replace the strength that the spot welds would have given.

Some rivets in this bit but a lot more spotwelds.

Old one out and a replacement from YRM again. Very accurate to the original but of course with none of the holes in so they all needed finding.

I've learned that you can't beat offering everything up on the vehicle with as many of the bits in place as possible. The times lately that some piece I thought was done and dusted has had to be changed because I forgot something else had altered.

For some reason ever since I took the seat box off I have been looking forward to getting round to fixing it. As it goes it has still been a long winded pain in the arse. That also has something to do with most of July looking like this.

With a bit more faffing we got there in the end.

The bolts here are just temporary while the puraflex goes off. They are where the seat runners will go. The rivet on the left is as it originally was but the two on the right are there (with the puraflex) to replace the strength that the spot welds would have given.

LincolnSteve

Well-Known Member

- Posts

- 1,224

- Location

- Lincoln

Update time. Drivers floor. Old one has the bit broken off where the hi/lo lever goes through and is so thin and corroded where it meets the bulkhead footwell that a new one is needed. As nothing standard fits I thought I had better make one.

Bit of a shame really as it's got that nice wear on it. Would be lost after refurbing anyway. I've had this sheet of tick aluminium in the garage for years. No idea where I nabbed it from originally. Combined with a bit of cereal packet template and we're off.

Leads to this. Still needs the holes drilling and the big hole for the hi/lo lever but it fits in the hole nicely and will keep my feet off the road.

Bit of a shame really as it's got that nice wear on it. Would be lost after refurbing anyway. I've had this sheet of tick aluminium in the garage for years. No idea where I nabbed it from originally. Combined with a bit of cereal packet template and we're off.

Leads to this. Still needs the holes drilling and the big hole for the hi/lo lever but it fits in the hole nicely and will keep my feet off the road.

LincolnSteve

Well-Known Member

- Posts

- 1,224

- Location

- Lincoln

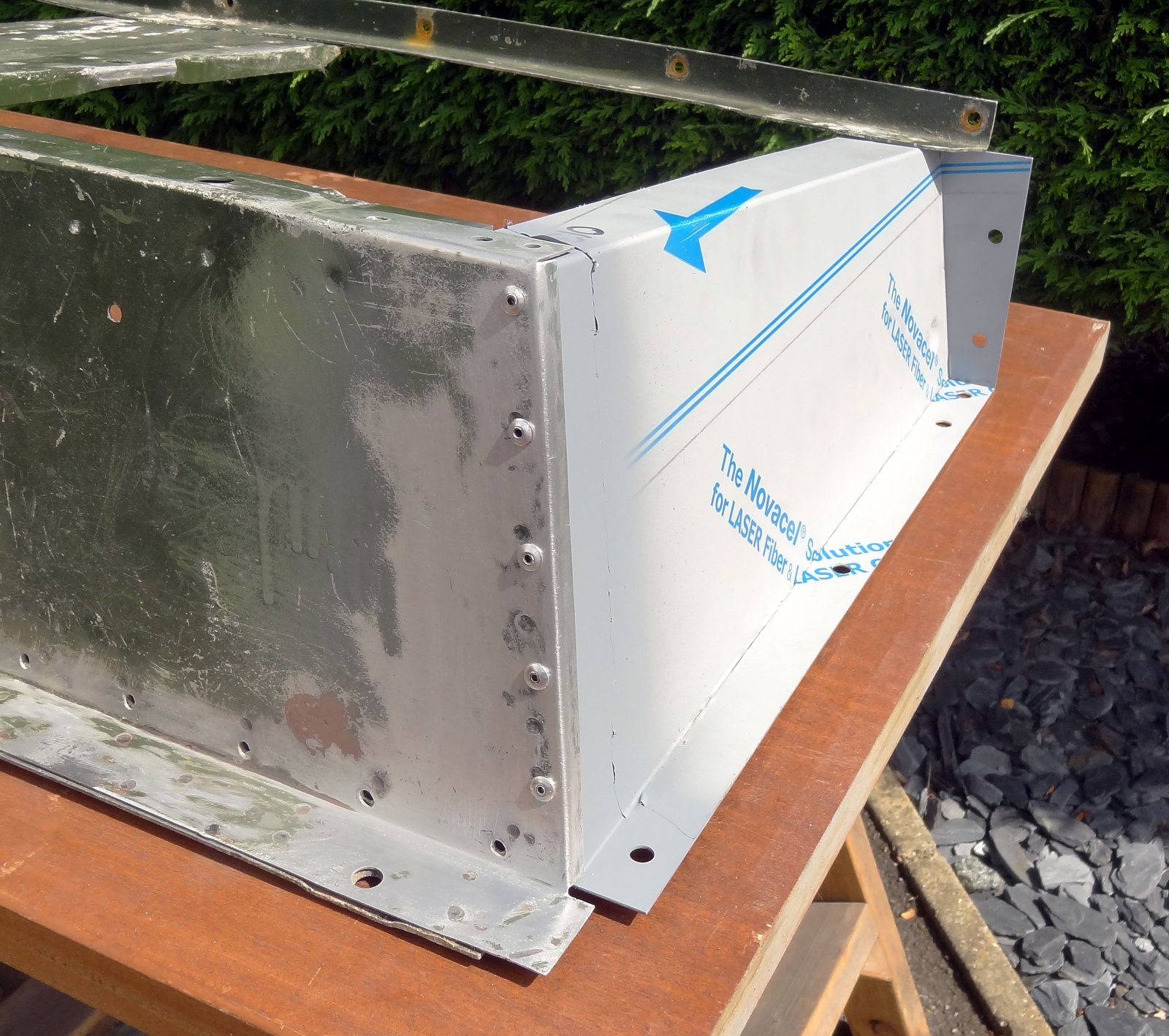

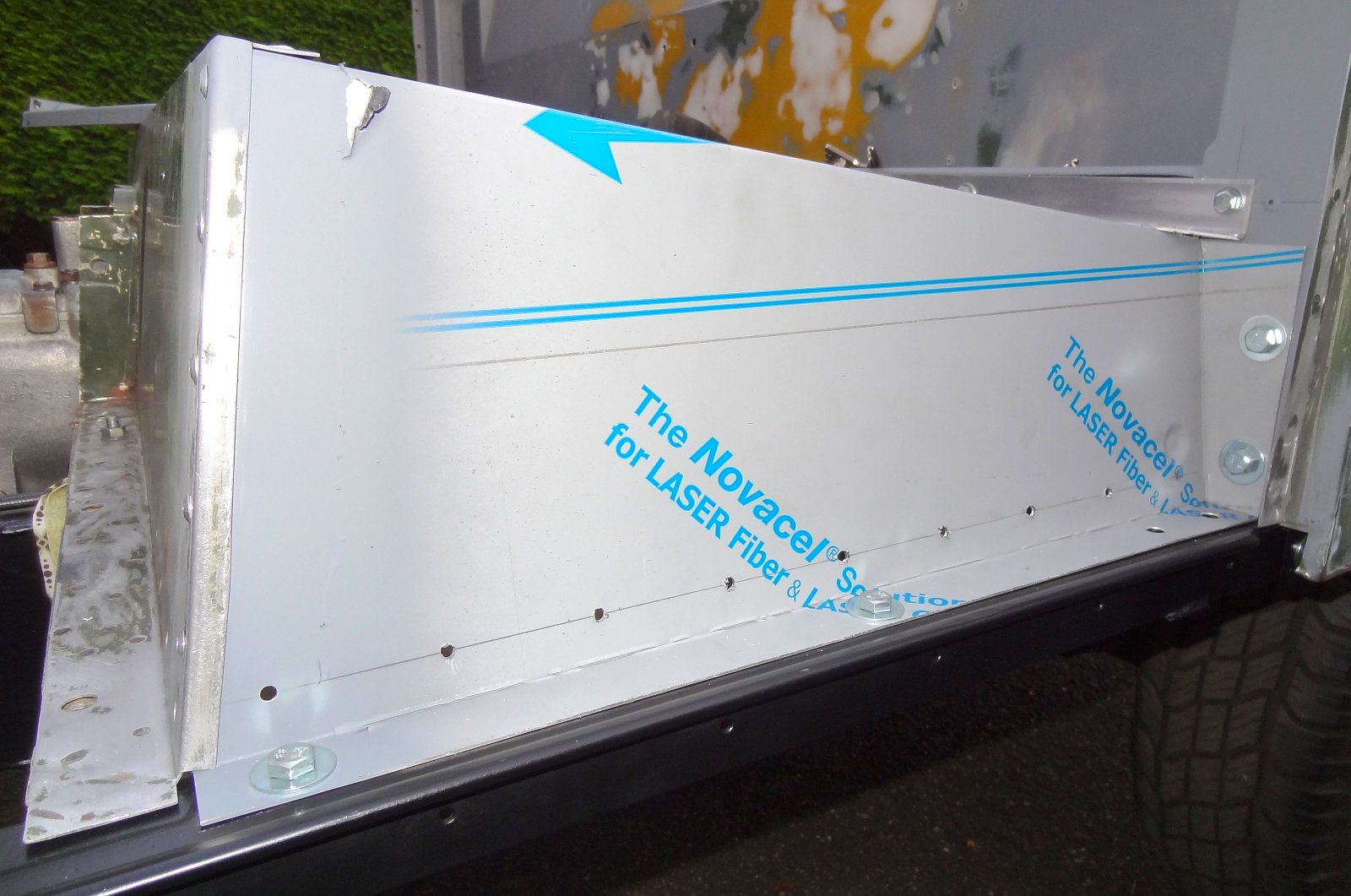

Back to the seat box. The toolbox under the passenger seat was really beyond help. Initially I thought I would make a new one when the time came but that was when I was young and daft. Now that i'm older and getting weary I got one from YRM. It's aluminium instead of steel so avoids the corrosion problems and lighter which will help later when I take it drag racing. It's really well made but there are a few joggled bits on the old one that aren't replicated so it doesn't fit 100% without a bit of fettling. If you don't it's only going to let water in from underneath into the toolbox that will get onto your sandwiches or whatever you've got in there.

Much offering up and head scratching later.

Much offering up and head scratching later.

LincolnSteve

Well-Known Member

- Posts

- 1,224

- Location

- Lincoln

Because I wanted to replace all the spot welds with rivets I thought I should trial fit all the seat runners. I could just imagine me getting a rivet head in somewhere and then not being able to fit the seat runner because of it. Another time consuming job. Some seat bits where up the house loft. Other bits in the loft space over the garage. The best thing about upholstery is it doesn't leak oil like every other bit I reassemble.

As for the covers over the holes in the seat box, the drivers side one is totally missing, not a big problem, just a flat sheet, I can make that. I have two covers but it seems that they are both the same but they shouldn't be. The one under the centre seat should be different to the one under the passenger seat. Can't decide whether to search out a second hand one or make something. Will depend on which I have more of, cash or time. Neither are very abundant.

As for the covers over the holes in the seat box, the drivers side one is totally missing, not a big problem, just a flat sheet, I can make that. I have two covers but it seems that they are both the same but they shouldn't be. The one under the centre seat should be different to the one under the passenger seat. Can't decide whether to search out a second hand one or make something. Will depend on which I have more of, cash or time. Neither are very abundant.

LincolnSteve

Well-Known Member

- Posts

- 1,224

- Location

- Lincoln

The biggest work recently though is priming and painting the bulkhead behind the seats. Primer went on last week and colour today. I sort of enjoy spraying. Even though i've hardly done any i'm sure it's a better bet for me than roller or brush. I'm not under any illusions about the finish i'm going to get but even so spraying is the one for me. One thing I do know is that I prefer bits off the car that I can stand in the garage and get around rather than bits like this where i'm clambering over the chassis, have no room and i'm constantly in my own light. Anyone considering spraying should know that it's stupid to try doing it in a single garage. I thought about having a go outside. Better light and plenty of space versus overspray turning the front of the house green and the wind blowing leaves and bugs onto my already sub standard workmanship. Went indoors. Overall it's a fair job. A couple of areas that I can't get the spray gun into inside the door pillar areas. They weren't covered well originally so looks like land rover had the same problem. I got a few runs, mostly in the primer which can be sorted. I also got one in the final coat though. Could also be sorted but because of the enamel paint not easily. It's going to be behind the passenger seat so i'll probably leave it. I'm soon going to have to stop using the excuse of 'you'll never see it once it's back together', and actually get better at spraying.

It's all a bit orange peely but beggars can't be choosers. I don't think I had the paint thin enough. I was sure I used the same amount of thinners as for the other bulkhead but I think seemed harder to get on this time. Will experiment with that next time.

It's all a bit orange peely but beggars can't be choosers. I don't think I had the paint thin enough. I was sure I used the same amount of thinners as for the other bulkhead but I think seemed harder to get on this time. Will experiment with that next time.

heli_madken

Well-Known Member

- Posts

- 104

- Location

- Scotland

Beautiful work and very inspiring to watch

LincolnSteve

Well-Known Member

- Posts

- 1,224

- Location

- Lincoln

Thank you.Beautiful work and very inspiring to watch

Bobsticle

De Villes Advocaat

- Posts

- 27,632

- Location

- Manchester

If your getting curtains your putting too much on. Old school coach painters would never attempt enamel in one coat. Their approach was to thin it to almost translucent and almost dust it on in layers with a flour paper down between. It’s a long winded process with huge amounts of drying time but that is how enamel rocks.

We have the advantage of scotchbright pads these days but they weren’t devoid of pumice dust on a damp rag.

I had the honour of working with an old boy who coach painted from being a kid. He’s long passed now but gave me a huge insight to the old ways. He taught me that because enamel is a hard finish to sand back between coats, the best way was to mix the primer with it in decreasing amounts. So pure primer first coat. Enamel with primer 50/50 on the next coat. 25/75 etc etc.

the slow colour change also helps with the subsequent passes.

Look on the bright side. He told me a story of one car company applying 16 coats to their vehicles.

We have the advantage of scotchbright pads these days but they weren’t devoid of pumice dust on a damp rag.

I had the honour of working with an old boy who coach painted from being a kid. He’s long passed now but gave me a huge insight to the old ways. He taught me that because enamel is a hard finish to sand back between coats, the best way was to mix the primer with it in decreasing amounts. So pure primer first coat. Enamel with primer 50/50 on the next coat. 25/75 etc etc.

the slow colour change also helps with the subsequent passes.

Look on the bright side. He told me a story of one car company applying 16 coats to their vehicles.

Bobsticle

De Villes Advocaat

- Posts

- 27,632

- Location

- Manchester

Please do me a massive favour Steve.

Before you forget, get hold of some car body knock on edge protector strip and line the hole in the bulkhead that the fuel filler comes through.

I’m on my third rubber filler pipe. All split as they pass through that ruddy hole. Not sure what bit is out of line but let’s face it, it could be anything, but my filler neck must rub on the sharp edge.

Before you forget, get hold of some car body knock on edge protector strip and line the hole in the bulkhead that the fuel filler comes through.

I’m on my third rubber filler pipe. All split as they pass through that ruddy hole. Not sure what bit is out of line but let’s face it, it could be anything, but my filler neck must rub on the sharp edge.

Similar threads

- Replies

- 9

- Views

- 747

- Replies

- 5

- Views

- 523

- Replies

- 2

- Views

- 510