You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Disco 2 Alternator Removal - Battery Red Warning Light

- Thread starter Intestinalworm

- Start date

This site contains affiliate links for which LandyZone may be compensated if you make a purchase.

Intestinalworm

Well-Known Member

- Posts

- 712

- Location

- Australia

I think my last alternator was killed by the vacuum pump as it was covered in oil.

Yes! I'm suspecting some leaking oil somewhere there - notice oil underneath the engine and oil over at the bottom end of the intercooler on the driver's side!! The front camshaft seal was replaced over a year ago and no oil leaking from there anymore.

Will see for sure when I finish removing it on Tuesday!

Last edited:

Intestinalworm

Well-Known Member

- Posts

- 712

- Location

- Australia

Yes put your leads on battery posts,12.6v is high, you sure you have your meter on on AC?

If thats 12.6volts AC your diode pack has failed..... You should get 0 or hardly anything as your right engine produces AC with alternator diode pack converts to DC so car can use it.

Check on your DC setting and see what you get. If your getting that amount of AC will be hardly anything.....AC is nasty causes lots of spikes and stuff...horrible!

2.1V per cell x 6 cells = 12.6V DC (no load - measured across battery posts).

JUKE179r

Well-Known Member

- Posts

- 3,165

- Location

- Suffolkshire

12.6VDC is a good voltage for a sitting battery but what is the voltage when the engine is running with the alternator?

Keep in mind... a battery can have good voltage and no/low amps.

Did you get any AC voltage readings across the battery posts while the engine is running?

Keep in mind... a battery can have good voltage and no/low amps.

Did you get any AC voltage readings across the battery posts while the engine is running?

Intestinalworm

Well-Known Member

- Posts

- 712

- Location

- Australia

"Checked battery terminals - nice and secure. Got multimeter and checked battery (battery only six months old) - 12.1V (DC). Turned ignition on and measured again: 11.8V (DC), then 2 seconds later it jumped to 12.9V (DC) with a change in sound!"

Removed battery and trickle charged - now 12.6V (DC). Removed a number of other items (battery box, ECU, intercooler pipe, etc.) to get good access, and pulling out alternator later today to inspect. Didn't measure AC volts at any time (didn't think to do that). The red battery light had come on and the measured DC voltage with the engine running was down from the normally measured 14.6V (DC), so that's what got me to conclude the alternator was the likely issue. Have now noticed a bit of oil down in that area, and of course the alternator (and brushes) are all original fitment (so 260,000km old).

I'll have to pull it out and see what I can conclude and then determine my options from there. I should have measured if there was any AC voltage (before I read your post) as a further diagnosis. Ultimately, if the brushes are worn right down then I will look to replace them but ideally I should also test the rectifier and the regulator - not sure how to do that either with the alternator out or installed back in place?

Removed battery and trickle charged - now 12.6V (DC). Removed a number of other items (battery box, ECU, intercooler pipe, etc.) to get good access, and pulling out alternator later today to inspect. Didn't measure AC volts at any time (didn't think to do that). The red battery light had come on and the measured DC voltage with the engine running was down from the normally measured 14.6V (DC), so that's what got me to conclude the alternator was the likely issue. Have now noticed a bit of oil down in that area, and of course the alternator (and brushes) are all original fitment (so 260,000km old).

I'll have to pull it out and see what I can conclude and then determine my options from there. I should have measured if there was any AC voltage (before I read your post) as a further diagnosis. Ultimately, if the brushes are worn right down then I will look to replace them but ideally I should also test the rectifier and the regulator - not sure how to do that either with the alternator out or installed back in place?

Intestinalworm

Well-Known Member

- Posts

- 712

- Location

- Australia

12.6VDC is a good voltage for a sitting battery but what is the voltage when the engine is running with the alternator?

Keep in mind... a battery can have good voltage and no/low amps.

Did you get any AC voltage readings across the battery posts while the engine is running?

Never measured AC at the time - didn't think to do that.

Intestinalworm

Well-Known Member

- Posts

- 712

- Location

- Australia

Okay, cannot budge the 13mm nut securing the positive lead to the alternator (underneath the rubber cover)! Difficult spot to access! Using 13mm socket and extension with a 1/4" ratchet. Cant' budge the bugger! If you have taken yours off, do you have any suggestions?

Intestinalworm

Well-Known Member

- Posts

- 712

- Location

- Australia

Okay, cannot budge the 13mm nut securing the positive lead to the alternator (underneath the rubber cover)! Difficult spot to access! Using 13mm socket and extension with a 1/4" ratchet. Can't budge the bugger! If you have taken yours off, do you have any suggestions?

Got the bugger (positive lead) off! Ended up using a 1/2" ratchet + 5" extension + 5" wobble extension + 13mm six-sided socket. Just in an awkward position! Didn't have to remove the fuel cooler (but of course battery, battery box, ECU, intercooler hose, fan, fan belt and tensioner all removed).

No skin off the knuckles yet!

Okay, now trying to get the 10mm bolt at the top off - secures the alternator to the block, along with the Torx 50 bolt at the bottom. Okay, thought the 10mm would be easy! Tried attacking from the right fender side with a ring spanner - no good! Decided to attack from the front with a 3/8" ratchet, 4" extension and a six-sided 10mm socket. Heard a click - wall of 10mm socket cracked in two spots!!!

Haven't started on the T50 bolt yet!

Will have to get another 10mm socket now. I have a T50 bit, but thinking I might need to get a T50 1/2" socket and attach to breaker bar or 1/2" ratchet? Any tips on tools and/or techniques to get the 10mm bolt (hidden behind that blasted oil pipe) and the T50 bolt out?

Also have to detach the vacuum hose - ring spanner/size?

Have the r-clip pliers for the oil drain hose, but not sure regards the size for the oil supply line pipe?

Last edited:

Intestinalworm

Well-Known Member

- Posts

- 712

- Location

- Australia

Okay, had a loose 10mm socket (1/2" drive) lying around! Detached the oil line from the cylinder head - 14mm open-ended spanner. (This is the one that needs the replacement o-ring). Enough room to tackle the 10mm bolt - this time with 1/2" ratchet and extension. All good - 10mm bolt removed.

Will get the T50 socket and remove the last bolt tomorrow.

With the vacuum line, can I just pull it out at the big unit on the firewall?

Will get the T50 socket and remove the last bolt tomorrow.

With the vacuum line, can I just pull it out at the big unit on the firewall?

- Posts

- 37,430

- Location

- North Shropshire

Progress is a good feeling!Okay, had a loose 10mm socket (1/2" drive) lying around! Detached the oil line from the cylinder head - 14mm open-ended spanner. (This is the one that needs the replacement o-ring). Enough room to tackle the 10mm bolt - this time with 1/2" ratchet and extension. All good - 10mm bolt removed.

Will get the T50 socket and remove the last bolt tomorrow.

With the vacuum line, can I just pull it out at the big unit on the firewall?

Intestinalworm

Well-Known Member

- Posts

- 712

- Location

- Australia

T50 3/8" socket with a short extension - all good getting the bottom bolt out. Removing the hardened/stiff vacuum pump drain line and the vaccuum line (to servo) required the hair dryer on high for three minutes to soften those stubborn buggers!!!

Last thing I'm trying to get off now is that damned plastic clip (with the two wires) at the back - supposed to just press and pull off!!! Don't want to break it! Any tips???

Last thing I'm trying to get off now is that damned plastic clip (with the two wires) at the back - supposed to just press and pull off!!! Don't want to break it! Any tips???

Intestinalworm

Well-Known Member

- Posts

- 712

- Location

- Australia

Got the clip (multiplug) off! Removed the intercooler EGR bypass elbow to get better access. Sprayed multiplug with WD-40 (using nozzle) and left for several minutes. Got a cloth to grip the oil-hardened plastic multiplug better; squeezed the top part of the multiplug down firmly and tried to wriggle it a tiny bit. Repeated the process with WD-40 again a bit later, and then I squeezed the multiplug again, tried to push it forward first, then tried to wriggle it a bit as I pulled it back, firmly pressing the top section! Worked - multiclip is free! Nothing broken - all good! Little lubricity helps!

Removed the intercooler EGR bypass elbow to get better access. Sprayed multiplug with WD-40 (using nozzle) and left for several minutes. Got a cloth to grip the oil-hardened plastic multiplug better; squeezed the top part of the multiplug down firmly and tried to wriggle it a tiny bit. Repeated the process with WD-40 again a bit later, and then I squeezed the multiplug again, tried to push it forward first, then tried to wriggle it a bit as I pulled it back, firmly pressing the top section! Worked - multiclip is free! Nothing broken - all good! Little lubricity helps!

Next problem - I have to get the unit (alternator and vacuum pump) out of the engine bay now! Not enough room between the front of the engine and the radiator (protected by hard cardboard) - the EGR (decommissioned) cooler that goes across the front in EU3 models now gets in the way! Tried pulling the alternator/vacuum pump out across to the driver's side fender (the battery box has been removed), but the blasted 1" coolant hose that goes to the underside of the EGR cooler gets in the way! (Doesn't look like the EGR cooler can be detached and moved out of the way a bit (with both hoses still attached.)

I thought getting it out of the engine bay was the easy bit? Is that only models (<EU3) without EGR coolers???

Maybe I just have to disconnect the 1" coolant hose from the underside of the EGR cooler so I can then pull out the alternator/vacuum pump towards the battery box area? Don't want to lose coolant though! Any thoughts?

[Just wanted to write this up for beginners like me! Not too hard a job - second time around if that ever happens will be a lot easier! It's been there for 18 years undisturbed, so bound to have some problems removing the bugger - still have to get it out, fix it and put it back yet!]

Next problem - I have to get the unit (alternator and vacuum pump) out of the engine bay now! Not enough room between the front of the engine and the radiator (protected by hard cardboard) - the EGR (decommissioned) cooler that goes across the front in EU3 models now gets in the way! Tried pulling the alternator/vacuum pump out across to the driver's side fender (the battery box has been removed), but the blasted 1" coolant hose that goes to the underside of the EGR cooler gets in the way! (Doesn't look like the EGR cooler can be detached and moved out of the way a bit (with both hoses still attached.)

I thought getting it out of the engine bay was the easy bit? Is that only models (<EU3) without EGR coolers???

Maybe I just have to disconnect the 1" coolant hose from the underside of the EGR cooler so I can then pull out the alternator/vacuum pump towards the battery box area? Don't want to lose coolant though! Any thoughts?

[Just wanted to write this up for beginners like me! Not too hard a job - second time around if that ever happens will be a lot easier! It's been there for 18 years undisturbed, so bound to have some problems removing the bugger - still have to get it out, fix it and put it back yet!]

Intestinalworm

Well-Known Member

- Posts

- 712

- Location

- Australia

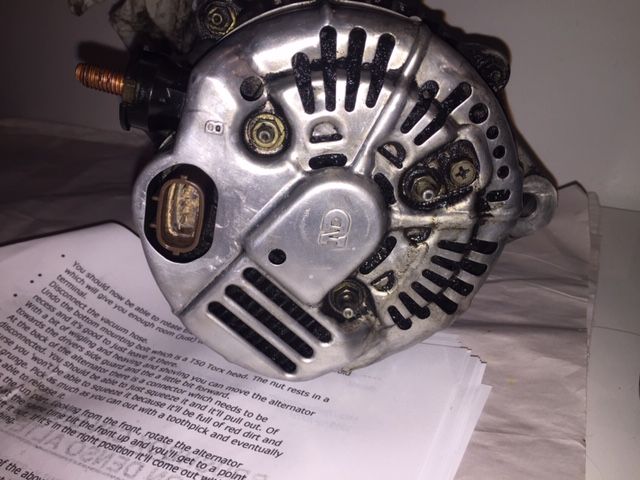

Got it out - wife assisted - better and safer with three hands! I didn't want to damage anything, especially those 1cm diameter hard plastic coolant lines coming from the radiator! Anyway, my wife just bent/twisted the EGR cooler bottom coolant hose (1" diameter) right back and out of the way - good thing it's flexible! I manoeuvred the alternator/vacuum pump out and up to the driver's side and out through the gap where the battery box and intercooler hose/elbow were (EGR valve by-passed); no coolant hoses removed, and no coolant lost!

Now to get it cleaned a bit and start dismantling - check those carbon brushes and see if I can also determine where the oil is coming from (vacuum pump lip seal?)!!!

All spinning well, no play, and no sounds or scratchiness - so assuming bearings okay for now.

Now to get it cleaned a bit and start dismantling - check those carbon brushes and see if I can also determine where the oil is coming from (vacuum pump lip seal?)!!!

All spinning well, no play, and no sounds or scratchiness - so assuming bearings okay for now.

Last edited:

PopPops

Well-Known Member

- Posts

- 503

- Location

- Fareham, Hampshire

This is a great guide - I feel your pain. I have the same to do before the warning light comes on (if the weather in this country ever warms up) as the alternator is oily and I also changed the front camshaft bung.Got it out - wife assisted - better and safer with three hands! I didn't want to damage anything, especially those 1cm diameter hard plastic coolant lines coming from the radiator! Anyway, my wife just bent/twisted the EGR cooler bottom coolant hose (1" diameter) right back and out of the way - good thing it's flexible! I manoeuvred the alternator/vacuum pump out and up to the driver's side and out through the gap where the battery box and intercooler hose/elbow were (EGR valve by-passed); no coolant hoses removed, and no coolant lost!

Now to get it cleaned a bit and start dismantling - check those carbon brushes and see if I can also determine where the oil is coming from (vacuum pump lip seal?)!!!

All spinning well, no play, and no sounds or scratchiness - so assuming bearings okay for now.

Looking forward to the next instalment!

Intestinalworm

Well-Known Member

- Posts

- 712

- Location

- Australia

Okay, it's out (first time in 18 years!) - nothing damaged in the process - yeah! (Have to take care working on old stuff, particularly plastic (multiplug) - goes hard and brittle with all that oil and heat!). Would have hated for the multiplug or radiator to be damaged! Wiped up the alternator/vacuum pump with baby wipes - it was bloody oily!!!

As a relative beginner DIYer this was a sense of achievement - ended up a bit more challenging in some ways than I expected - getting that multiplug and the vac hose and oil drain hose off, along with the general access! Used a hair dryer on the hoses to soften them and get them off - made a huge difference! Printed out some info and tips (RAVE is a good start - but misses so much detail) to help me and watched the following on YouTube:

(he made it a bit harder than it should be and he admitted as much!)

and

(in Italian - but a great How To video)

Will have a look at the carbon brushes tomorrow! Certain I'll at least be buying a new brush box - 18 years (260K) is a long time!

Geez I love working on the Landy - next door neighbour won't even change a flat tyre or a light globe, and said to me today that he would just get a new car! I laughed! I just love working on the Disco!

As a relative beginner DIYer this was a sense of achievement - ended up a bit more challenging in some ways than I expected - getting that multiplug and the vac hose and oil drain hose off, along with the general access! Used a hair dryer on the hoses to soften them and get them off - made a huge difference! Printed out some info and tips (RAVE is a good start - but misses so much detail) to help me and watched the following on YouTube:

(he made it a bit harder than it should be and he admitted as much!)

and

(in Italian - but a great How To video)

Will have a look at the carbon brushes tomorrow! Certain I'll at least be buying a new brush box - 18 years (260K) is a long time!

Geez I love working on the Landy - next door neighbour won't even change a flat tyre or a light globe, and said to me today that he would just get a new car! I laughed! I just love working on the Disco!

Intestinalworm

Well-Known Member

- Posts

- 712

- Location

- Australia

Now! Oil! I put a new front camshaft seal in a while ago, but there was historical oil build-up from that I know.

What are the other sources of oil? Assuming vacuum pump lip seal??? Assuming vacuum pump oil feed hose inlet - copper washers worn perhaps??? Anything I should check regards oil?

What are the other sources of oil? Assuming vacuum pump lip seal??? Assuming vacuum pump oil feed hose inlet - copper washers worn perhaps??? Anything I should check regards oil?

Intestinalworm

Well-Known Member

- Posts

- 712

- Location

- Australia

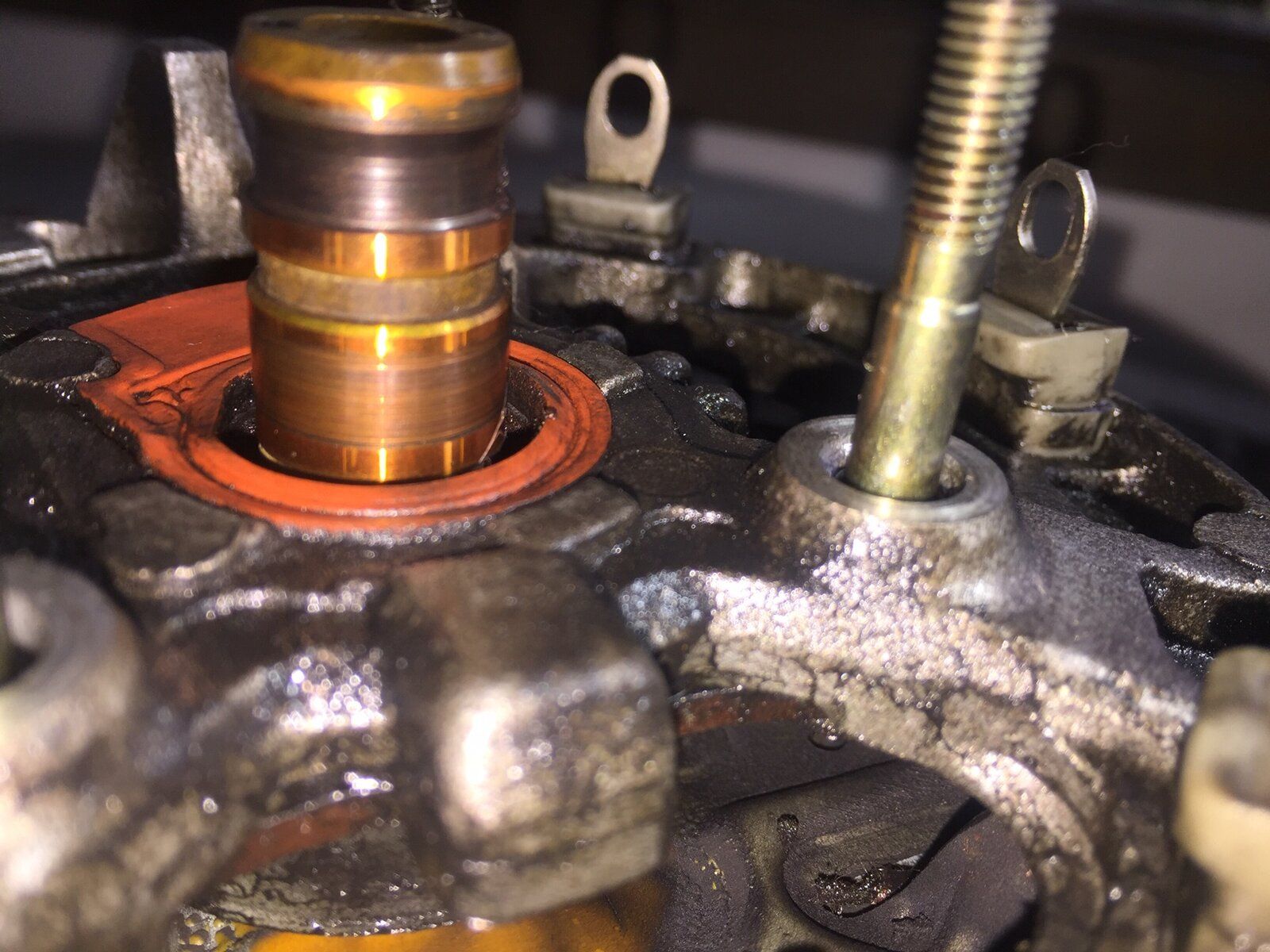

Okay, alternator was a bit oily (original Denso alternator with original brushes for 260,000km). Removed the back tin cover and then removed the brush box holder. Brushes were worn down as you would expect, but what I really noticed was some sludge - oil, grit and the orange hue of copper dust! The slip-ring towards the front of the shaft was fine, but I was shocked to see that the rear slip-ring was largely worn away - no copper colour! So, it looks like oil and grit got between the rear brush and the rear slip-ring at some stage in the last 18 years and acted like cutting paste I guess! The rear carbon brush was consequently worn down around 3mm more than the front carbon brush!

So, looks like I'll buy a new brush box holder and pick-up a used alternator for now. I can keep my old unit for spares (regulator and rectifier).

See pic below - with worn/gouged slip-ring at the top (back end of the shaft):

Wish I'd had a better outcome - still, 18 years is a good innings I guess!

Came across some good info and videos along the way that might be helpful for Beginner Mechanics like myself:

https://sparkys-answers.com/2010/10/changing-brushes-in-denso-alternator.html

(testing an alternator)

Any thought/suggestions from anyone experienced with these things? Maybe someone has replaced slip-rings? (Apparently here in Australia, the slip-rings are available from a place called Baxters (https://www.baxters.com.au/slip-ring-nippondenso-8-8-x-14-5mm.html) - part number is NSR1). Told it's easy to do, but I don't solder, and not sure about the epoxy?!

So, looks like I'll buy a new brush box holder and pick-up a used alternator for now. I can keep my old unit for spares (regulator and rectifier).

See pic below - with worn/gouged slip-ring at the top (back end of the shaft):

Wish I'd had a better outcome - still, 18 years is a good innings I guess!

Came across some good info and videos along the way that might be helpful for Beginner Mechanics like myself:

https://sparkys-answers.com/2010/10/changing-brushes-in-denso-alternator.html

(testing an alternator)

Any thought/suggestions from anyone experienced with these things? Maybe someone has replaced slip-rings? (Apparently here in Australia, the slip-rings are available from a place called Baxters (https://www.baxters.com.au/slip-ring-nippondenso-8-8-x-14-5mm.html) - part number is NSR1). Told it's easy to do, but I don't solder, and not sure about the epoxy?!

Last edited:

Similar threads

- Replies

- 4

- Views

- 654

- Replies

- 10

- Views

- 1K