Jam1

Well-Known Member

- Posts

- 1,315

- Location

- Staffordshire

Knowing Aaron he probably used a massive amount of "elbow grease" and a tooth brushThat cleaning looks awesome. What did you clean the steering box and tank with?

Knowing Aaron he probably used a massive amount of "elbow grease" and a tooth brushThat cleaning looks awesome. What did you clean the steering box and tank with?

That cleaning looks awesome. What did you clean the steering box and tank with?

Apparently not. Ah well, I bought a 4 bolt box off ebay for £20 instead.

Knowing Aaron he probably used a massive amount of "elbow grease" and a tooth brush

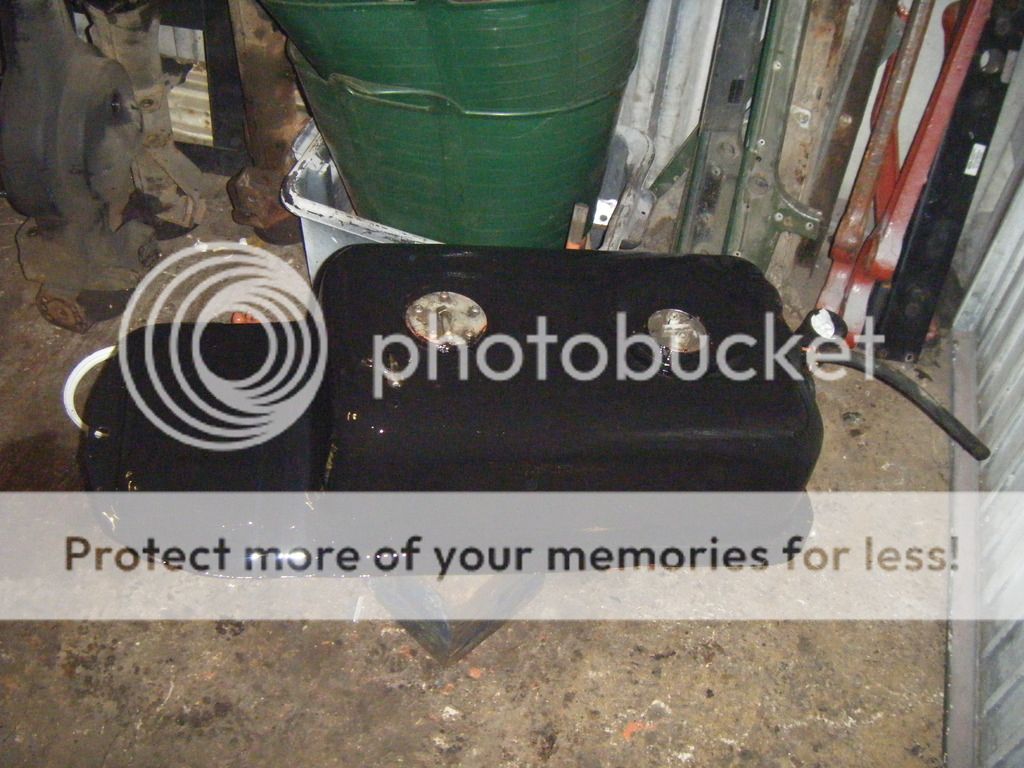

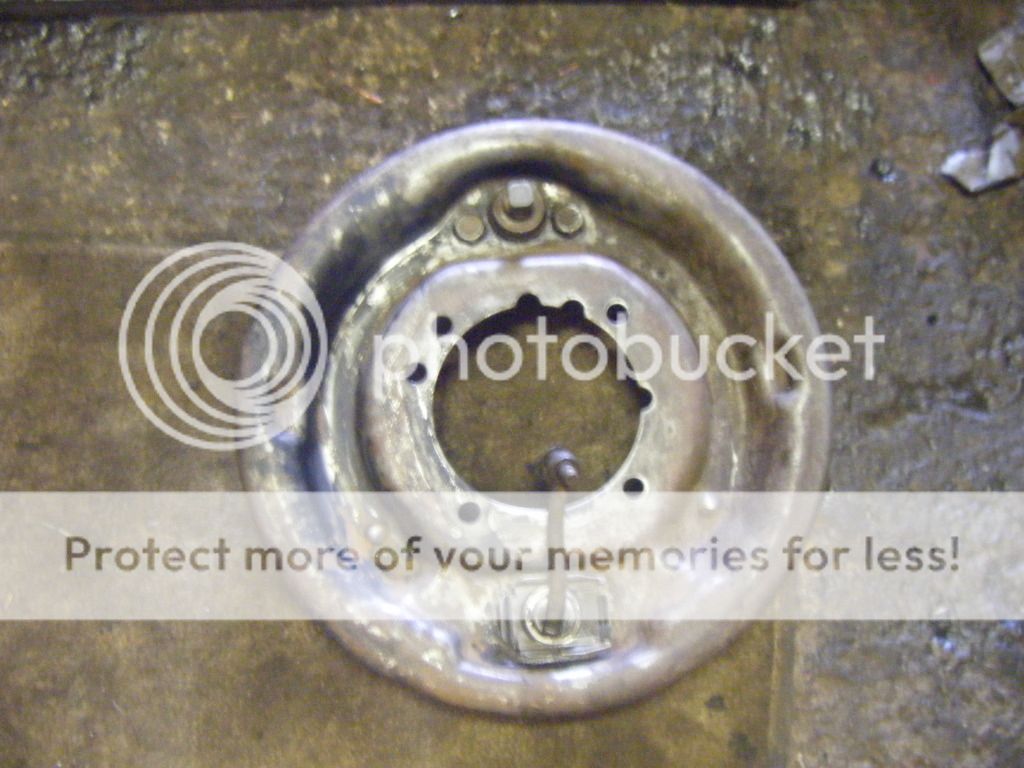

It's not too bad mate, just a dirty job, wire brush on the grinder soon got all the crap off the fuel tank, and wire wheel in the drill sorted the steering box, with a little cleaning of old oil etc before hand, a parts washer would be nice for stuff like the steering box.

Get the filler etc wrapped with cling film or something. Mine was brand new and the pipes and holes were either wrapped or had a stopper in. One stopper had a split in and I was storing it in the back of the landy under a tarp. Still got a dribble of water in it and got a small patch of rust. Made it a lot worse with vinegar. Mind you, yours might be better as it's already got a covering of diesel in there.2nd coat tomorrow, then got to find somewhere safe to store it all until ready, seriously running out of room.

Good quality wire wheels those! Lots and lots of time by the sound of it too.

Get the filler etc wrapped with cling film or something. Mine was brand new and the pipes and holes were either wrapped or had a stopper in. One stopper had a split in and I was storing it in the back of the landy under a tarp. Still got a dribble of water in it and got a small patch of rust. Made it a lot worse with vinegar. Mind you, yours might be better as it's already got a covering of diesel in there.

looking good aaron. Buzzweld s2 goes alot further than you thinkinvert the tin after each re-seal so it doesn't cure off.

Hi Aaron what type of puller do you use to pull the output shafts with as trying to find a suitable one off eBay or the likes ASAP as I'm going away in it next weekend.

That rubber thing, is it 515466?

Re blasting - two weeks ago I dropped some bits off at the blisters and he was so busy he actually offered to lend/sell me his small blasting pot so I could do it myself. I considered it but mainly can't be doing with the mess. I thought about putting a shed up in the drive (Mrs permitting), blasting everything I could think of including a disco chassis I have, and then getting rid. Then I wondered if a 14cfm compressor could keep up. Then just thought is it really worth it? More expense, more stuff to store. But you have room for the extra shed..........

If I was to do another rebuild I would definitely sort out a blasting pot before I started. When I think of the hours I've put in rubbing things down, using the needle gun, wire and abrasive wheels and still not being that happy with the result. You live and learn

To be fair I'm happy with my prep most of the time, albeit very time consuming at times, only got to go the blasting route because I want to galv a lot of things. Me and my bloody idea's, made life slightly difficult, should have sorted it from day one as I'm now in a predicament as to what to do. sigh!

Welcome To LandyZone, the Land Rover Forums!

Here at LandyZone we have plenty of very knowledgable members so if you have any questions about your Land Rover or just want to connect with other Landy owners, you're in the right place.

Registering is free and easy just click here, we hope to see you on the forums soon!