roule's latest activity

This site contains affiliate links for which LandyZone may be compensated if you make a purchase.

-

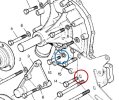

roule replied to the thread water pump broken bolt.Finally, i forgot one hidden bolt (blue one) !! the water goes out through this hole. I dry it ,and put a new bolt with sealant on the thread.i leave the broken bolt (red one) as this. Tomorrow, i will fill water again ... 🤞

roule replied to the thread water pump broken bolt.Finally, i forgot one hidden bolt (blue one) !! the water goes out through this hole. I dry it ,and put a new bolt with sealant on the thread.i leave the broken bolt (red one) as this. Tomorrow, i will fill water again ... 🤞 -

roule replied to the thread water pump broken bolt.stud extractor broken inside :mad: i wasn't straight. I tried to put water ...and of course big leak...so water pump removal work in progress... I will purchase tungsten drill to remove all this ...

roule replied to the thread water pump broken bolt.stud extractor broken inside :mad: i wasn't straight. I tried to put water ...and of course big leak...so water pump removal work in progress... I will purchase tungsten drill to remove all this ... -

roule replied to the thread RRC EFI 3,9 first crank after rebuild.i will empty the tank before fitting new gazoline i put pure water (no glycol) in the radiator i prime the oil pump with the drill i give 2 rotations of the engine with a wrench i put back the dizzy i crank the engine and put an eye on the oil...

roule replied to the thread RRC EFI 3,9 first crank after rebuild.i will empty the tank before fitting new gazoline i put pure water (no glycol) in the radiator i prime the oil pump with the drill i give 2 rotations of the engine with a wrench i put back the dizzy i crank the engine and put an eye on the oil... -

roule replied to the thread RRC EFI 3,9 first crank after rebuild.That means i should remove the fuel pump to empty the tank...

roule replied to the thread RRC EFI 3,9 first crank after rebuild.That means i should remove the fuel pump to empty the tank... -

roule replied to the thread RRC EFI 3,9 first crank after rebuild.Its E 10 ...

roule replied to the thread RRC EFI 3,9 first crank after rebuild.Its E 10 ... -

roule replied to the thread RRC EFI 3,9 first crank after rebuild.I have 10 liters fuel in the tank since 2 years, if i mix with new gazoline it's ok , or i must empty the tank before ?

roule replied to the thread RRC EFI 3,9 first crank after rebuild.I have 10 liters fuel in the tank since 2 years, if i mix with new gazoline it's ok , or i must empty the tank before ? -

roule replied to the thread RRC EFI 3,9 first crank after rebuild.i have to fix the dizzy yes ! that's could be my last job ;)

roule replied to the thread RRC EFI 3,9 first crank after rebuild.i have to fix the dizzy yes ! that's could be my last job ;) -

roule replied to the thread RRC EFI 3,9 first crank after rebuild.2000 rpm during almost 10 minutes ?

roule replied to the thread RRC EFI 3,9 first crank after rebuild.2000 rpm during almost 10 minutes ? -

roule replied to the thread RRC V8 3,9 vogue SE vaccum hoses setting.Ifound! the cut hose goes to a switch near the pedal, i succeed to connect a new hose there , from a T that goes to the vacuum pump and the CC actuator. Don't know why this hose was cutted ... And the plenum connection goes to a vacuum ball that...

roule replied to the thread RRC V8 3,9 vogue SE vaccum hoses setting.Ifound! the cut hose goes to a switch near the pedal, i succeed to connect a new hose there , from a T that goes to the vacuum pump and the CC actuator. Don't know why this hose was cutted ... And the plenum connection goes to a vacuum ball that... -

roule replied to the thread RRC V8 3,9 vogue SE vaccum hoses setting.I wonder which hose connect on the yellow circle mark ??? first one through the bulkhead, the hose was cut 2nd on the plenum

roule replied to the thread RRC V8 3,9 vogue SE vaccum hoses setting.I wonder which hose connect on the yellow circle mark ??? first one through the bulkhead, the hose was cut 2nd on the plenum -

roule replied to the thread RRC V8 3,9 vogue SE vaccum hoses setting.May be only for the upgraded VOGUE SE ?

roule replied to the thread RRC V8 3,9 vogue SE vaccum hoses setting.May be only for the upgraded VOGUE SE ? -

roule replied to the thread Rover V8 3,9 oil pump pressure.I just tighten the crank bolt with my wrench that is limited to 240 NM , i gave a little more , about 20 °, as the torque should be 270 NM ...should be OK .

roule replied to the thread Rover V8 3,9 oil pump pressure.I just tighten the crank bolt with my wrench that is limited to 240 NM , i gave a little more , about 20 °, as the torque should be 270 NM ...should be OK . -

roule replied to the thread Rover V8 3,9 oil pump pressure.That would be THE moment ...with new lifters and camshaft...hope no trouble or issue at this time 🙏

roule replied to the thread Rover V8 3,9 oil pump pressure.That would be THE moment ...with new lifters and camshaft...hope no trouble or issue at this time 🙏 -

roule replied to the thread water pump broken bolt.I ordered yesterday (i needed it) a new compact drill machine and a left hand drill ...should do it

roule replied to the thread water pump broken bolt.I ordered yesterday (i needed it) a new compact drill machine and a left hand drill ...should do it -

roule replied to the thread water pump broken bolt.Not a lot of place to do that (i dont want to remove again the timing cover) but the bolt should not be tightened hard. I have to find a little drill...

roule replied to the thread water pump broken bolt.Not a lot of place to do that (i dont want to remove again the timing cover) but the bolt should not be tightened hard. I have to find a little drill... -

roule replied to the thread water pump broken bolt.It's already cut, in the middle of the treads ! You mean i should cut it like this and fill the hole with loctite and then with a RTV sealant ? that's it ?

roule replied to the thread water pump broken bolt.It's already cut, in the middle of the treads ! You mean i should cut it like this and fill the hole with loctite and then with a RTV sealant ? that's it ? -

roule replied to the thread camshaft bolt RRC V8 EFI 3,9.The oil pump gasket, not easy to find, is not a paper one, i think i can re use it...it's a bit plastic made.

roule replied to the thread camshaft bolt RRC V8 EFI 3,9.The oil pump gasket, not easy to find, is not a paper one, i think i can re use it...it's a bit plastic made. -

roule replied to the thread camshaft bolt RRC V8 EFI 3,9.I finally remove the front cover, the bolt was tightened correctly to 5O NM :mad:,do not need to crank the pulley... I need now to get new gaskets (oil pump and front cover) and reset again ...

roule replied to the thread camshaft bolt RRC V8 EFI 3,9.I finally remove the front cover, the bolt was tightened correctly to 5O NM :mad:,do not need to crank the pulley... I need now to get new gaskets (oil pump and front cover) and reset again ...