pwood999's latest activity

This site contains affiliate links for which LandyZone may be compensated if you make a purchase.

-

pwood999 replied to the thread Freelander 1 [New Title] Bad Idle, high Fuel Consumption & grey smoke..Update. Firstly stipped and cleaned the injectors, inlet manifold, inlet ports. Then cleaned out all the carbon build-up from injector-2 port in the head (other three were fairly clean but did them as well). Cleaned out the vortex crank...

pwood999 replied to the thread Freelander 1 [New Title] Bad Idle, high Fuel Consumption & grey smoke..Update. Firstly stipped and cleaned the injectors, inlet manifold, inlet ports. Then cleaned out all the carbon build-up from injector-2 port in the head (other three were fairly clean but did them as well). Cleaned out the vortex crank... -

pwood999 replied to the thread [P38] Exhaust gases in coolant.Coolant pressure tester & LED Inspection mirror. Get the engine warmed up first. Then switch off & pressurise the cooling system to about 14psi. The rear block core plugs will be inside the bell-housing, so check around the bottom...

pwood999 replied to the thread [P38] Exhaust gases in coolant.Coolant pressure tester & LED Inspection mirror. Get the engine warmed up first. Then switch off & pressurise the cooling system to about 14psi. The rear block core plugs will be inside the bell-housing, so check around the bottom... -

pwood999 replied to the thread [P38] Exhaust gases in coolant.Unlikely to be the upper manifold. Either the valley is not quite sealed at the back, or could be the rear head core plugs ? There's also a couple of core plugs on the rear of the block, behind the flywheel.

pwood999 replied to the thread [P38] Exhaust gases in coolant.Unlikely to be the upper manifold. Either the valley is not quite sealed at the back, or could be the rear head core plugs ? There's also a couple of core plugs on the rear of the block, behind the flywheel. -

pwood999 replied to the thread Freelander 1 [New Title] Bad Idle, high Fuel Consumption & grey smoke..Got the injectors out today. 1,3 & 4 popped out fairly easily with a flat bar on the plastic cover to support my pry-bar. Number-2 needed my slide hammer pictured above, but eventually came out. Took all the tips off, and cleaned them out so...

pwood999 replied to the thread Freelander 1 [New Title] Bad Idle, high Fuel Consumption & grey smoke..Got the injectors out today. 1,3 & 4 popped out fairly easily with a flat bar on the plastic cover to support my pry-bar. Number-2 needed my slide hammer pictured above, but eventually came out. Took all the tips off, and cleaned them out so... -

pwood999 reacted to Datatek's post in the thread L322 pulling my hair out! (Not much left) with

pwood999 reacted to Datatek's post in the thread L322 pulling my hair out! (Not much left) withLike.

No way I would rely on the air suspension when going under the car. -

pwood999 replied to the thread P38A 2000 EDC Bad Starting.yes I beleive so, but only check using gauge, not diagnostics. Nanocom EDC fueling menu doesn't seem to show temperature like my GEMS.

pwood999 replied to the thread P38A 2000 EDC Bad Starting.yes I beleive so, but only check using gauge, not diagnostics. Nanocom EDC fueling menu doesn't seem to show temperature like my GEMS. -

pwood999 replied to the thread P38A 2000 EDC Bad Starting.ok. It's a 2000 car so my guess would be the later filter, so good one to try next. For the FIP adjustment any links to photos or video on what to loosen & adjust ? The procedure in RAVE seems to be quite involved. Do all the injector pipes...

pwood999 replied to the thread P38A 2000 EDC Bad Starting.ok. It's a 2000 car so my guess would be the later filter, so good one to try next. For the FIP adjustment any links to photos or video on what to loosen & adjust ? The procedure in RAVE seems to be quite involved. Do all the injector pipes... -

pwood999 replied to the thread Range rover td6 airride.playing music ?? Next video delete the music & rotate your phone !! A new compressor should fill the tank & get the system to normal height in about 4-5mins. If the car is already up at height, then tank should fill faster. if it takes...

pwood999 replied to the thread Range rover td6 airride.playing music ?? Next video delete the music & rotate your phone !! A new compressor should fill the tank & get the system to normal height in about 4-5mins. If the car is already up at height, then tank should fill faster. if it takes... -

pwood999 replied to the thread P38A 2000 EDC Bad Starting.So he popped round again this morning & had another look. As I don't have a dial-gauge & zero familiarity of the FIP, etc I'm not gonna risk touching that. Checked underneath and no obvious leaks from tank pipes. All the fittings appear to...

pwood999 replied to the thread P38A 2000 EDC Bad Starting.So he popped round again this morning & had another look. As I don't have a dial-gauge & zero familiarity of the FIP, etc I'm not gonna risk touching that. Checked underneath and no obvious leaks from tank pipes. All the fittings appear to... -

pwood999 replied to the thread Range rover td6 airride.Get the exact model from the label on the pump. Then call X8R or 4x4-Airseals, and they will tell you what refurb kit to use. Prices range from £20 to £60 depending on whether it a Wabco or hitachi pump.

pwood999 replied to the thread Range rover td6 airride.Get the exact model from the label on the pump. Then call X8R or 4x4-Airseals, and they will tell you what refurb kit to use. Prices range from £20 to £60 depending on whether it a Wabco or hitachi pump. -

pwood999 replied to the thread P38A Rear hub assembly FTC3223 from Eurospares anyone tried them?.Will keep an eye on them.

pwood999 replied to the thread P38A Rear hub assembly FTC3223 from Eurospares anyone tried them?.Will keep an eye on them. -

pwood999 replied to the thread Range rover td6 airride.If your compressor is getting that hot trying to fill the tank & bags, it probably could do with a rebuild. Otherwise it will let you down & either fail or blow the fuse again.

pwood999 replied to the thread Range rover td6 airride.If your compressor is getting that hot trying to fill the tank & bags, it probably could do with a rebuild. Otherwise it will let you down & either fail or blow the fuse again. -

pwood999 replied to the thread [P38] Exhaust gases in coolant.I use either Nanocom, or a basic Bluetooth OBD reader to check temps after coolant system repairs. But generally only for the first few runs.

pwood999 replied to the thread [P38] Exhaust gases in coolant.I use either Nanocom, or a basic Bluetooth OBD reader to check temps after coolant system repairs. But generally only for the first few runs. -

pwood999 replied to the thread P38A Thor vs Gems drive train differences.Not quite. Although the block & heads are basicall the same, the camshaft pulleys, crank & cam sensors are different between GEMS & Thor. Obviously the intake, but also the coils & brackets. Cooling system pipe routing & radiator are different.

pwood999 replied to the thread P38A Thor vs Gems drive train differences.Not quite. Although the block & heads are basicall the same, the camshaft pulleys, crank & cam sensors are different between GEMS & Thor. Obviously the intake, but also the coils & brackets. Cooling system pipe routing & radiator are different. -

pwood999 replied to the thread M57 classic conversion.Def not a diseasel expert, but several people have been saying stay away from M57, but that the N57 535 is much better ?? (always fun to pipe in on a thread I know nothing about)

pwood999 replied to the thread M57 classic conversion.Def not a diseasel expert, but several people have been saying stay away from M57, but that the N57 535 is much better ?? (always fun to pipe in on a thread I know nothing about) -

pwood999 replied to the thread P38A Thor vs Gems drive train differences.As above, what parts are you swapping ? If it's just the drivetrain (based on the first post & title), then the only mechanical difference is the 4-pin front diff in the Thor. Is something bad on the Thor that needs replacing ?

pwood999 replied to the thread P38A Thor vs Gems drive train differences.As above, what parts are you swapping ? If it's just the drivetrain (based on the first post & title), then the only mechanical difference is the 4-pin front diff in the Thor. Is something bad on the Thor that needs replacing ? -

pwood999 replied to the thread P38A Rear hub assembly FTC3223 from Eurospares anyone tried them?.Turns out the offside axle seal was well worn & it clearly had a gap around the half-shaft. Nearside as better but still not sealing well. Both bearing housings had loads of rust inside, so clearly water had been getting in there. LR-CAT...

pwood999 replied to the thread P38A Rear hub assembly FTC3223 from Eurospares anyone tried them?.Turns out the offside axle seal was well worn & it clearly had a gap around the half-shaft. Nearside as better but still not sealing well. Both bearing housings had loads of rust inside, so clearly water had been getting in there. LR-CAT... -

pwood999 replied to the thread P38A Headlining repair.I spoke with several about a Freelander headlining earlier this week, but most of them avoid doing headlinings if possible. One said £400 and that's with me delivering it already out of the car. P38 is much easier than many cars because there's...

pwood999 replied to the thread P38A Headlining repair.I spoke with several about a Freelander headlining earlier this week, but most of them avoid doing headlinings if possible. One said £400 and that's with me delivering it already out of the car. P38 is much easier than many cars because there's... -

pwood999 replied to the thread P38A Rear hub assembly FTC3223 from Eurospares anyone tried them?.RAVE doesn't mention it, but is it worth putting a bead of RTV around the hub flange where it goes into the axle ? Or just rely on the bolts to seal the hub & keep water, etc away from the back of the wheel bearing ?

pwood999 replied to the thread P38A Rear hub assembly FTC3223 from Eurospares anyone tried them?.RAVE doesn't mention it, but is it worth putting a bead of RTV around the hub flange where it goes into the axle ? Or just rely on the bolts to seal the hub & keep water, etc away from the back of the wheel bearing ? -

pwood999 replied to the thread Freelander 1 Freelander EV.That's not your problem. It might be a one-off, but yours is a legitimate registered leccy vehicle.

pwood999 replied to the thread Freelander 1 Freelander EV.That's not your problem. It might be a one-off, but yours is a legitimate registered leccy vehicle. -

pwood999 replied to the thread P38A Thor vs Gems drive train differences.If the 4-pin & 2-pin are both standard ratio, then the only reall difference is the 4-pin is generally stronger. Transfer & gearbox differ between 4.0L & 4.6L.

pwood999 replied to the thread P38A Thor vs Gems drive train differences.If the 4-pin & 2-pin are both standard ratio, then the only reall difference is the 4-pin is generally stronger. Transfer & gearbox differ between 4.0L & 4.6L. -

pwood999 replied to the thread Range rover td6 airride.For reference the Merc Wabco I use on the bench takes about 2-3 mins to fill a 5 litre tank. So running your compressor & seeing only 1.6bar then it probably needs a rebuild. To be sure run it for 5mins manually & then check the pressure. If...

pwood999 replied to the thread Range rover td6 airride.For reference the Merc Wabco I use on the bench takes about 2-3 mins to fill a 5 litre tank. So running your compressor & seeing only 1.6bar then it probably needs a rebuild. To be sure run it for 5mins manually & then check the pressure. If... -

pwood999 replied to the thread Range rover td6 airride.Alternatively connect a pressure gauge either to the pump output, or in place of the sensor. Then run the pump & see what you get.

pwood999 replied to the thread Range rover td6 airride.Alternatively connect a pressure gauge either to the pump output, or in place of the sensor. Then run the pump & see what you get. -

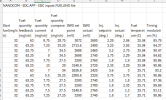

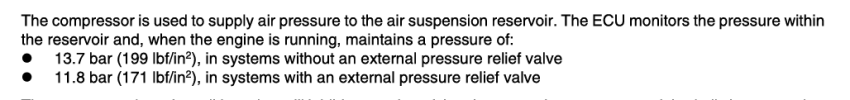

pwood999 replied to the thread Range rover td6 airride.In good condition a Wabco should easily do 160-180psi. From the docs I posted above:

pwood999 replied to the thread Range rover td6 airride.In good condition a Wabco should easily do 160-180psi. From the docs I posted above: -

pwood999 replied to the thread 3 Amigo without codes.Although they are different Wabco ECU's officially the P38 Wabco-C stops diagnostics at a speed over 1.6mph (2km/h). My P38 gets to about 4mph before shutting data off, but that's probably low-speed error limit. Interestingly the Nanocom docs...

pwood999 replied to the thread 3 Amigo without codes.Although they are different Wabco ECU's officially the P38 Wabco-C stops diagnostics at a speed over 1.6mph (2km/h). My P38 gets to about 4mph before shutting data off, but that's probably low-speed error limit. Interestingly the Nanocom docs... -

pwood999 replied to the thread Range rover td6 airride.If you can run the compressor (either with diagnostics or simply apply 12V to it), and monitor the pressure sensor. If you can get some air in the system, get some soapy water & look for leaks. Also have a read of these docs to understand how...

pwood999 replied to the thread Range rover td6 airride.If you can run the compressor (either with diagnostics or simply apply 12V to it), and monitor the pressure sensor. If you can get some air in the system, get some soapy water & look for leaks. Also have a read of these docs to understand how... -

pwood999 replied to the thread air suspension.I thought they are Wabco or Hitachi pumps ?? X8R do rebuild kits for both. I have a Mercedes Wabco in my garage I use for valve block testing. X8R kit was easy to fit.

pwood999 replied to the thread air suspension.I thought they are Wabco or Hitachi pumps ?? X8R do rebuild kits for both. I have a Mercedes Wabco in my garage I use for valve block testing. X8R kit was easy to fit. -

pwood999 replied to the thread Freelander 1 Freelander EV.So how many "AliBro ECU's" does the car have now ??

pwood999 replied to the thread Freelander 1 Freelander EV.So how many "AliBro ECU's" does the car have now ??