steve2286w

Well-Known Member

- Posts

- 4,092

- Location

- monkeyangerland

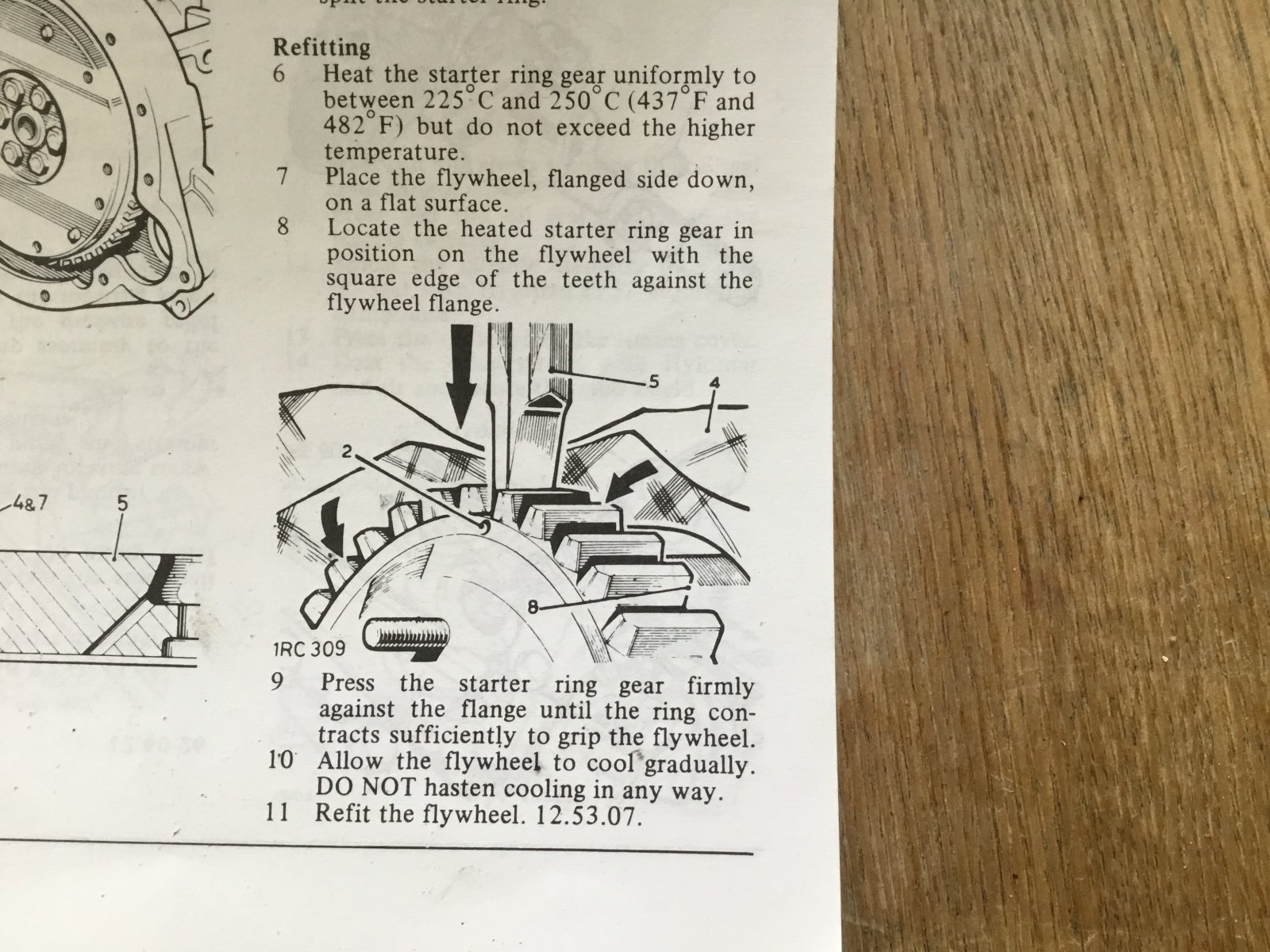

Replacing the ring gear on my 5mb diesel flywheel, old one off easy enough

having a mare getting new one on, next try I’m now heating it above the recommended 250C to 260C and cooling flywheel in freezer but not sure if the cold flywheel more of a hindrance as it might cool the ring gear tooo quickly

anyone got experience of doing this successfully

having a mare getting new one on, next try I’m now heating it above the recommended 250C to 260C and cooling flywheel in freezer but not sure if the cold flywheel more of a hindrance as it might cool the ring gear tooo quickly

anyone got experience of doing this successfully