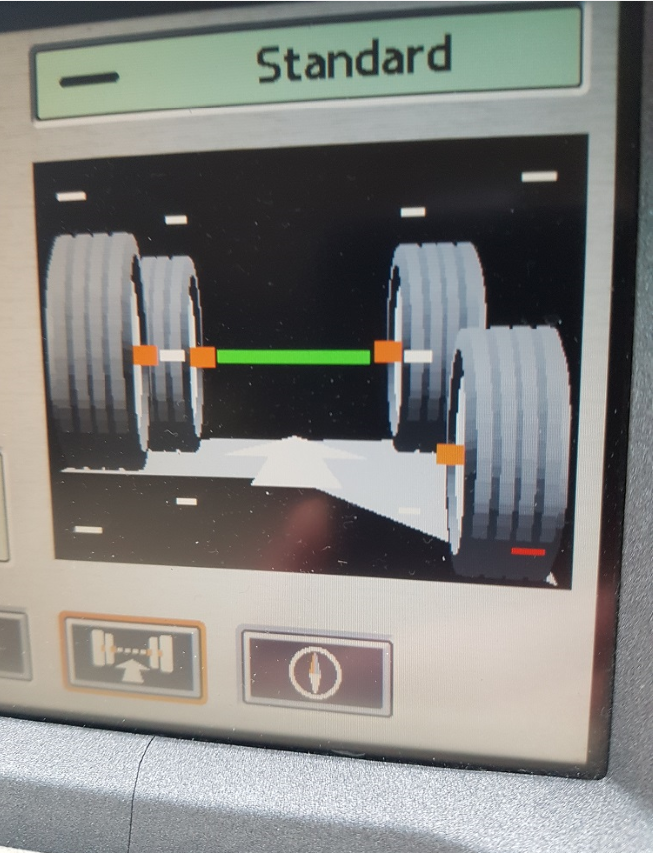

I suspect if it wasn't transmitting heights you would see an error on the 4x4 screen something like this but for the front wheel.

The variations in Red may be because of the uneven ground so each corner will have slightly different heights. If my logic is correct 1 corner will be spot on but the other 3 will be higher or lower depending on the ground variation.

The variations in Red may be because of the uneven ground so each corner will have slightly different heights. If my logic is correct 1 corner will be spot on but the other 3 will be higher or lower depending on the ground variation.