Bobsticle

De Villes Advocaat

- Posts

- 27,632

- Location

- Manchester

Being all posh and too sensitive for roughing it in a tent I wanted to make a camper trailer for my series for when out on little adventures.

Attempting to keep it age related I came up with the idea of a wood burner for heating but more importantly it would give me something to do till spring and the main build.

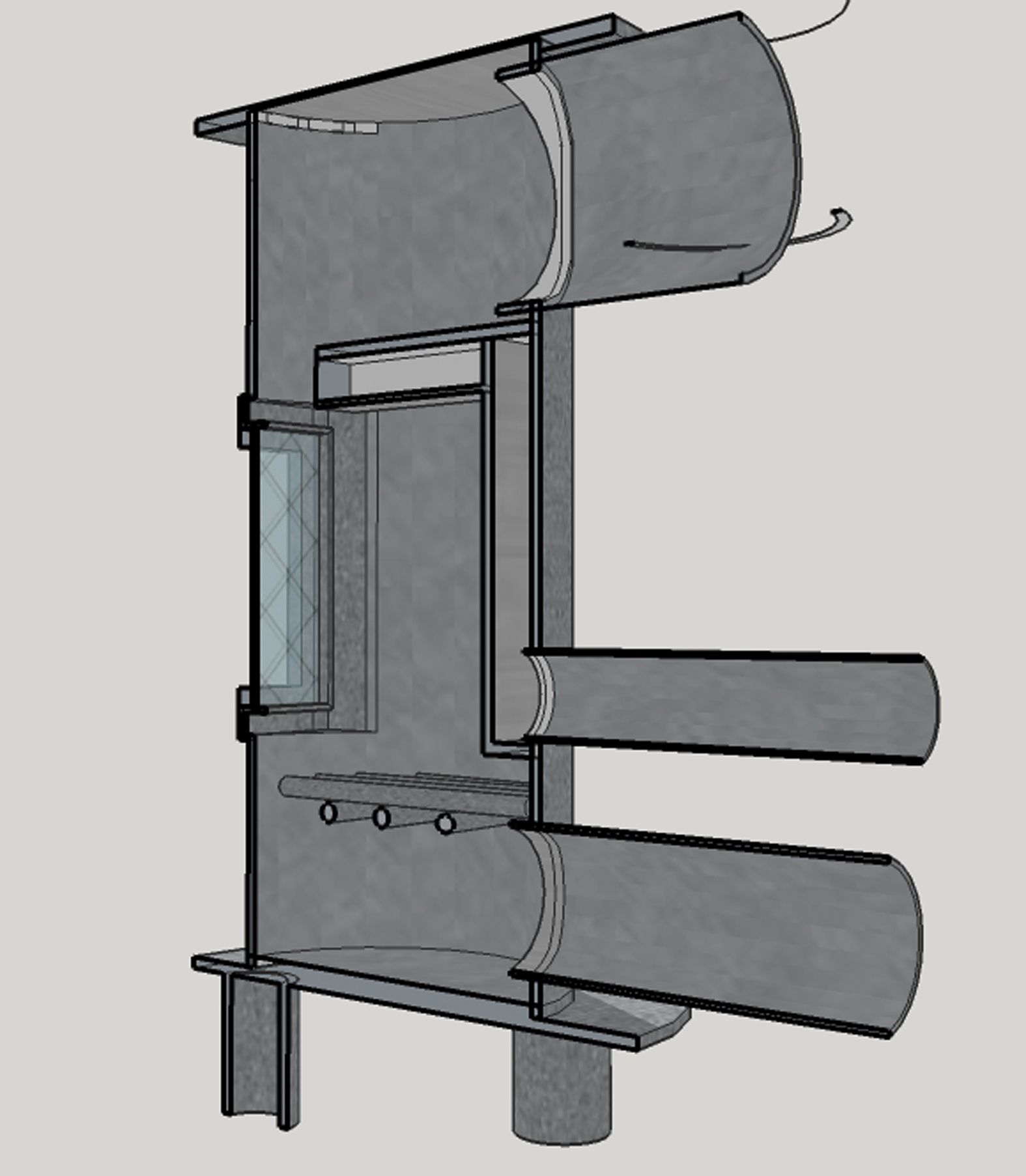

First thing I did was some designs and ideas.

1. it cant use air from inside as it will use up all your oxygen and kill ye dead.

2. It has to be small or it will get too hot and kill ye dead.

3. It has to be safe or the lot will go up in flames and kill ye dead.

4. it has to be a smokeless one or the world will end and it'll kill us all dead.

Ok easy peasy . Paper design.

. Paper design.

Managed to pick up a scuba tank for the body and being 6mm thick should outlast a normal gas tank.

Marked out and chopped up a bit. Time to do some skip ratting as I dont like buying things.

I was going to chop the bottom off but came up the idea of a screw on trap on the bottom to empty the ash out. Off to the sprinkler system engineers and a fiver later came away with a 2" barrel nipple and end cap. I really do need to practice my welding

Having a secondary burn to reduce smoke requires a baffle and chamber so just above the door goes a lump of steel plate with a 'cut out' of similar area to the planned three inch stove pipe.

This gets fitted about 4 inches from the top edge with copious dollops of run away welding

Now for the fun bit. A separate 1" air intake brings air through the back of the tank and up the back wall behind a plate. Once heated the air passes though a piece of box section and squirts out all over the rising smoke. This reignites and the re heated smoke/unburnt fuel is passed under the hot plate and out through t, t'chimley.

Firstly I made the plate and burner......

and then fitted it.

10 cutting discs later the welder came out again.

I have two welders but my little MIG will only go up to a few mill. This lots like ship building so the big point and spray stick welder was given a blast.

It never looked that good again

Before blasting into position I had to cut the inch hole in the back. Tried everything I had available and trust me that isnt alot (did I mention I was tight) so in the end the welder was turned up to nuclear and I burnt a rough hole in the back ready to attack with some grinding stones later. Yes it will take a long time but its all I have.

Once molten steel was smudged all over it in ever worsening passes I tested the burner by jamming a blow torch in the hole and holding a naked flame around the welds. It didnt kill me to death So you can put up with me for a little longer.

So you can put up with me for a little longer.

Its so beautiful................................

Started losing the light a bit but it was time for legs. Wanted round ens but had free square.

Time to retire to the shed and cut up some more discs coz I luv buying discs I duz.

When you have legs you need feet. You also get fewer discs.

Well thats it for today. I have spent money and am awaiting steel for the door frame and door.

Just need a lamp post now

Attempting to keep it age related I came up with the idea of a wood burner for heating but more importantly it would give me something to do till spring and the main build.

First thing I did was some designs and ideas.

1. it cant use air from inside as it will use up all your oxygen and kill ye dead.

2. It has to be small or it will get too hot and kill ye dead.

3. It has to be safe or the lot will go up in flames and kill ye dead.

4. it has to be a smokeless one or the world will end and it'll kill us all dead.

Ok easy peasy

Managed to pick up a scuba tank for the body and being 6mm thick should outlast a normal gas tank.

Marked out and chopped up a bit. Time to do some skip ratting as I dont like buying things.

I was going to chop the bottom off but came up the idea of a screw on trap on the bottom to empty the ash out. Off to the sprinkler system engineers and a fiver later came away with a 2" barrel nipple and end cap. I really do need to practice my welding

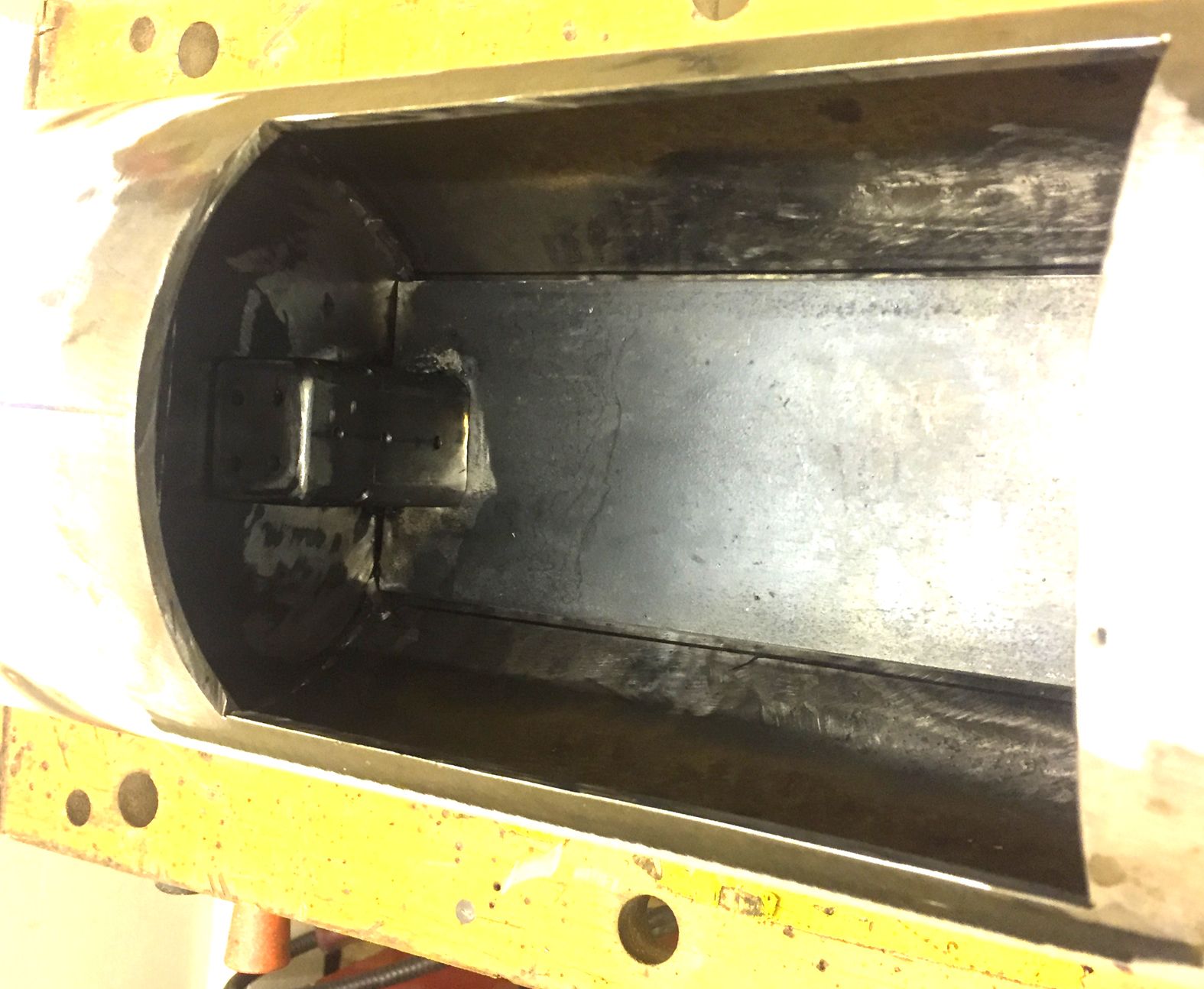

Having a secondary burn to reduce smoke requires a baffle and chamber so just above the door goes a lump of steel plate with a 'cut out' of similar area to the planned three inch stove pipe.

This gets fitted about 4 inches from the top edge with copious dollops of run away welding

Now for the fun bit. A separate 1" air intake brings air through the back of the tank and up the back wall behind a plate. Once heated the air passes though a piece of box section and squirts out all over the rising smoke. This reignites and the re heated smoke/unburnt fuel is passed under the hot plate and out through t, t'chimley.

Firstly I made the plate and burner......

and then fitted it.

10 cutting discs later the welder came out again.

I have two welders but my little MIG will only go up to a few mill. This lots like ship building so the big point and spray stick welder was given a blast.

It never looked that good again

Before blasting into position I had to cut the inch hole in the back. Tried everything I had available and trust me that isnt alot (did I mention I was tight) so in the end the welder was turned up to nuclear and I burnt a rough hole in the back ready to attack with some grinding stones later. Yes it will take a long time but its all I have.

Once molten steel was smudged all over it in ever worsening passes I tested the burner by jamming a blow torch in the hole and holding a naked flame around the welds. It didnt kill me to death

Its so beautiful................................

Started losing the light a bit but it was time for legs. Wanted round ens but had free square.

Time to retire to the shed and cut up some more discs coz I luv buying discs I duz.

When you have legs you need feet. You also get fewer discs.

Well thats it for today. I have spent money and am awaiting steel for the door frame and door.

Just need a lamp post now