You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Suspension issue

- Thread starter S8oxl

- Start date

This site contains affiliate links for which LandyZone may be compensated if you make a purchase.

sierrafery

Well-Known Member

- Posts

- 17,168

- Location

- Arad/Romania

Seems a wiring issue to that module

sierrafery

Well-Known Member

- Posts

- 17,168

- Location

- Arad/Romania

According to the WSM for that code you'll have to scan the suspension module too, if no code stored in that one i have no ideea:Thanks any idea where it start lol

| U0421-68 | Invalid Data Received from Suspension Control Module A - Event information |

|

|

1988smithy

Well-Known Member

- Posts

- 3,901

- Location

- West midlands

Gap iid

1988smithy

Well-Known Member

- Posts

- 3,901

- Location

- West midlands

No idea, my indy uses snap thoThanks my mate has a

22.2 SPECIAL EDITION SNAP-ON SOLUS Legend,

Would that work

sierrafery

Well-Known Member

- Posts

- 17,168

- Location

- Arad/Romania

The tool which retrieved that first code seems good enough

plus 1 ^^^^

hi

hope u don’t mind me adding but that’s one of the worst things u can do by changing part after part trying to resolve the original fault

by changing multiple parts u start to introduce further items that could be at fault, not unheard of new parts being faulty from out the box

is that the only code u have plse as see there’s an ABS issue, have u carried out a full scan of all the modules , any errors on any plse

indeed as you’ve replaced all the height sensors a full suspension re calibration will be required as a starting point

do u still have all the old parts plse and why were they changed , , personally if u still have them I would refit them back and then do a full rescan , then go through the system step by step, including testing the abs sensors , associated wiring connectors throughout the vehicle

how did u test the suspension module plse

sorry for all the questions but justr is not feel you’ve made it considerably worse , alas I had to virtually rebuild my entire suspension system when i bought my D3 , but that was down to neglect from previous owners, I tested each item including the main loom/ connectors on each and every item ensuring 100% it was faulty before replacement

hope that also helps u

hi

hope u don’t mind me adding but that’s one of the worst things u can do by changing part after part trying to resolve the original fault

by changing multiple parts u start to introduce further items that could be at fault, not unheard of new parts being faulty from out the box

is that the only code u have plse as see there’s an ABS issue, have u carried out a full scan of all the modules , any errors on any plse

indeed as you’ve replaced all the height sensors a full suspension re calibration will be required as a starting point

do u still have all the old parts plse and why were they changed , , personally if u still have them I would refit them back and then do a full rescan , then go through the system step by step, including testing the abs sensors , associated wiring connectors throughout the vehicle

how did u test the suspension module plse

sorry for all the questions but justr is not feel you’ve made it considerably worse , alas I had to virtually rebuild my entire suspension system when i bought my D3 , but that was down to neglect from previous owners, I tested each item including the main loom/ connectors on each and every item ensuring 100% it was faulty before replacement

hope that also helps u

Last edited:

Meant to add do u have a multimeter plse as that’s also a very useful tool to have

plse ensure ur battery is fully charged , u can do basic testing with a er multimeter

lastly I’m not critising u as that’s the last thing I wish to do , just feel you’ve made it considerably worse with all the parts changing

plse ensure ur battery is fully charged , u can do basic testing with a er multimeter

lastly I’m not critising u as that’s the last thing I wish to do , just feel you’ve made it considerably worse with all the parts changing

sierrafery

Well-Known Member

- Posts

- 17,168

- Location

- Arad/Romania

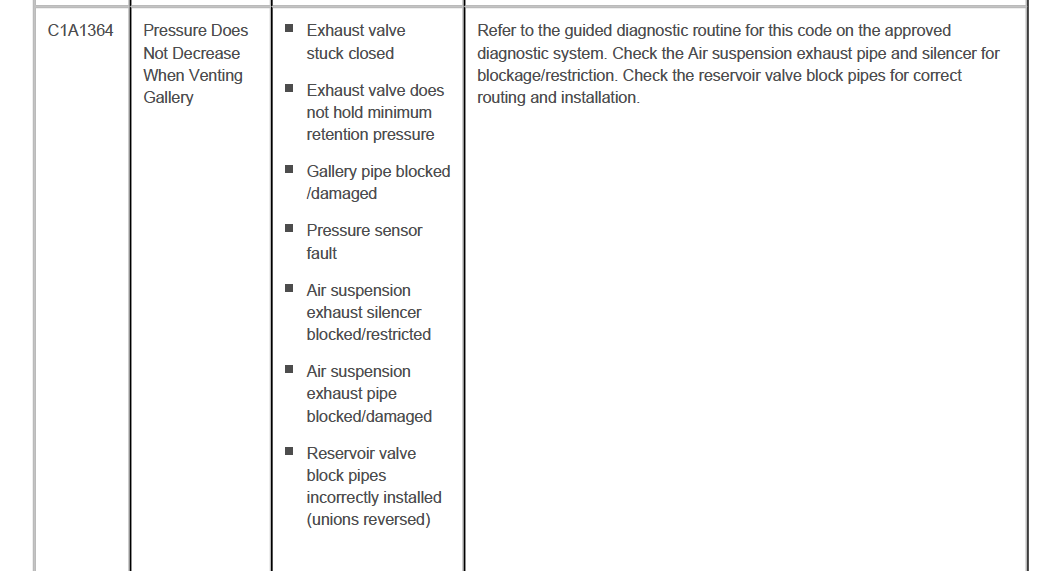

Now you are closer to the problem, here's from the WSM:

sierrafery

Well-Known Member

- Posts

- 17,168

- Location

- Arad/Romania

I have to personal experience with this fault so you should check what's recommended by LR in that list

sierrafery

Well-Known Member

- Posts

- 17,168

- Location

- Arad/Romania

AAMOF there are bulletins on this, according to the second one it can be a software issue too

1. https://static.nhtsa.gov/odi/tsbs/2016/MC-10105682-9340.pdf

2. https://static.nhtsa.gov/odi/tsbs/2018/MC-10144563-9999.pdf

1. https://static.nhtsa.gov/odi/tsbs/2016/MC-10105682-9340.pdf

2. https://static.nhtsa.gov/odi/tsbs/2018/MC-10144563-9999.pdf

sierrafery

Well-Known Member

- Posts

- 17,168

- Location

- Arad/Romania

The system is the same

Similar threads

- Replies

- 22

- Views

- 2K