sitec

New Member

- Posts

- 137

- Location

- Cockatoo Valley, South Australia!

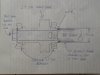

Before the Cummins could go in, I had to make an LT230 fit the ZF 5-42 which sits behind the 6 pot. Now, this has been done before by Nick (nrs91) and now by a few others.. Still holding u responsible Nick!!!  . So with that in mind, I set about making a plate to get them mated..... This involved several pieces op paper, several measurements and a lot of drilling!!!!

. So with that in mind, I set about making a plate to get them mated..... This involved several pieces op paper, several measurements and a lot of drilling!!!!