cheezels

Member

- Posts

- 94

- Location

- Tewantin, Australia

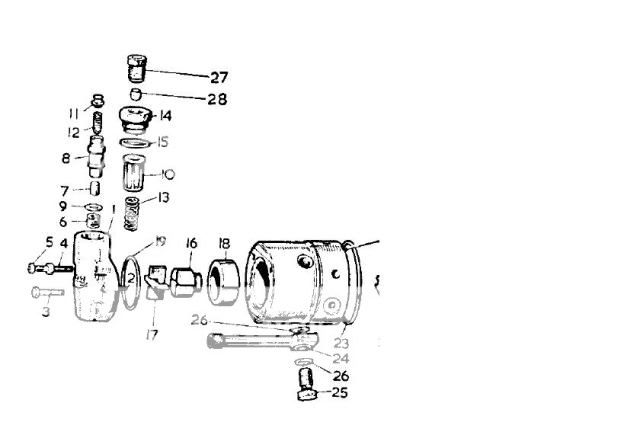

I've been giving the Landie the once over and read somewhere that there is a filter on the inlet side of the distributor fuel pump.

So, I removed it to give it a clean and now I can't remember which way it goes back together :doh:

I will post a pic later of the bits that came out (filter, spring and what looks like a guide and summat else)........but in the mean time, does anyone have a drawing??

What a donkey!!

So, I removed it to give it a clean and now I can't remember which way it goes back together :doh:

I will post a pic later of the bits that came out (filter, spring and what looks like a guide and summat else)........but in the mean time, does anyone have a drawing??

What a donkey!!