You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Freelander 1 K Series engine Timing

- Thread starter Andy J

- Start date

This site contains affiliate links for which LandyZone may be compensated if you make a purchase.

Hi, yes the fuel pump is priming and there is a spark as well just won't fire up.Only if he's been turning things with no belt on and completely ignored timing marks. Is the fuel pump priming when ign is switched on?

htr

Well-Known Member

- Posts

- 1,515

- Location

- Central Otago, Southern New Zealand

Nodge68

Well-Known Member

- Posts

- 32,504

- Location

- Near Newquay

Timing the K good enough to run is easy. However sometimes the timing appears to be 1/2 a tooth out. This doesn't stop it running, it just makes it less powerful.

It's important to accurately time the engine, or damage to valves and power running/non starting will result.

The cam pulleys should really be locked with a locking tool, if movement while routing the belt is to be avoided.

Iirc the flywheel can and should be locked with a suitable sized drill shank through the hole in the gearbox adapter plate, which means the timing can't shift when the belt is being fitted.

It's important to accurately time the engine, or damage to valves and power running/non starting will result.

The cam pulleys should really be locked with a locking tool, if movement while routing the belt is to be avoided.

Iirc the flywheel can and should be locked with a suitable sized drill shank through the hole in the gearbox adapter plate, which means the timing can't shift when the belt is being fitted.

I'v checked the timing and everything looks fine but as the crank pulley rotates twice to the cam pulleys once that's why I wondered if it was 180 deg out.Before fitting the new cam belt did he align the cam pulleys and have the crank pulley sitting at its mark?

Nodge68

Well-Known Member

- Posts

- 32,504

- Location

- Near Newquay

I'v checked the timing and everything looks fine but as the crank pulley rotates twice to the cam pulleys once that's why I wondered if it was 180 deg out.

The crankshaft can't be 180° out, only the cams can be 180° out.

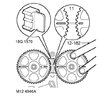

As long as the timing marks on the cam pulleys are in line, and adjacent to each other,

J_D

Well-Known Member

- Posts

- 561

- Location

- Worcestershire

If the crank timing mark refers to top dead centre, you need to confirm that is for cylinder 1 and cams at correct timing.

That can be done by removing spark plug and using something in the bore to go up with the piston, like a long stick.

But turning it over without the belt off and cams in place could cause valve damage. Get him to tell you his complete procedure.

That can be done by removing spark plug and using something in the bore to go up with the piston, like a long stick.

But turning it over without the belt off and cams in place could cause valve damage. Get him to tell you his complete procedure.

Nodge68

Well-Known Member

- Posts

- 32,504

- Location

- Near Newquay

If the crank timing mark refers to top dead centre, you need to confirm that is for cylinder 1 and cams at correct timing.

The K series is timed at 90° BTDC.

Anything is possible Andy. Can you get the engine to TDC and check the alignment of the cam pulleys? Should look like the photo that Nodge posted above. Take a picture and post here?Hi trying to help out a neighbour out with his Rover 25 DOHC he's put a new timing belt on and it won't start is it possible to get the timing 180 deg's out any help would be great cheers.

This will be something simple - and if the only thing that has changed is the timing belt, then it'll be something related to that...

Alibro

Well-Known Member

- Posts

- 7,024

- Location

- Northern Ireland

Did he have the Cam pulleys off? If so he may have refitted them wrong as I did once when doing the HG.

The inlet pulley has to have the pin in the centre (hidden by the bolts in Nodge's photo) at the inlet position and the exhaust pulley pin should be at the EX position.

It's easy to get it wrong if you're not aware of the correct positioning of the centre pins and the pulleys are the same. You can take the bolts out without causing any problems to check.

The inlet pulley has to have the pin in the centre (hidden by the bolts in Nodge's photo) at the inlet position and the exhaust pulley pin should be at the EX position.

It's easy to get it wrong if you're not aware of the correct positioning of the centre pins and the pulleys are the same. You can take the bolts out without causing any problems to check.

Hi everybody I'v had a look both cam pulleys look the same He's had them off along with everything else tried swapping the cam pulleys, changing the timing 180 and it's still not starting there is a good spark and the plugs have fuel on them any further help would be great Cheers

Alibro

Well-Known Member

- Posts

- 7,024

- Location

- Northern Ireland

Did you check the pins were in the right place in the centre of the pulleys (hidden by the bolts) like I said in my last post?

J_D

Well-Known Member

- Posts

- 561

- Location

- Worcestershire

cam pulleys are specific to inlet and exhaust.

Is there any compression when turning over (bent valves?)

Is there any compression when turning over (bent valves?)

andyfreelandy

Well-Known Member

- Posts

- 5,121

- Location

- Devon

Rather than swapping pulleys and shifting timing 180 degrees to see what happens !!!

I'd read the above guidance and this useful thread to see if you can spot the problem. If all is aligned as shown, pins, cams, crank then all should be well assuming there isn't a bent valve or two now!

https://www.landyzone.co.uk/land-rover/wont-start-after-hg-change.331454/

I'd read the above guidance and this useful thread to see if you can spot the problem. If all is aligned as shown, pins, cams, crank then all should be well assuming there isn't a bent valve or two now!

https://www.landyzone.co.uk/land-rover/wont-start-after-hg-change.331454/

Nodge68

Well-Known Member

- Posts

- 32,504

- Location

- Near Newquay

Hi everybody I'v had a look both cam pulleys look the same He's had them off along with everything else tried swapping the cam pulleys, changing the timing 180 and it's still not starting there is a good spark and the plugs have fuel on them any further help would be great Cheers

The exhaust and inlet cam pulleys are the same. You simply use the correct locking pin location on the pulley, which is relevant to the cam it's fitted.

So on the exhaust cam, the pin goes in the slot marked EX, and on the inlet cam, the pin goes in the slot marked IN. This is all that's needed, as doing so will then align the cams correctly, when all the timing marks line up.

Randomly fitting the pulleys in the wrong place, will simply result in bent valves, as the K series is an interference engine, like most engines these days.

Last edited:

Similar threads

Freelander 1

Engine mounts (timing belt)

- Replies

- 6

- Views

- 782

Freelander 2 (LR2)

Engine Removal Sequence

- Replies

- 1

- Views

- 434

- Replies

- 8

- Views

- 514