Herald

Member

- Posts

- 84

- Location

- East London

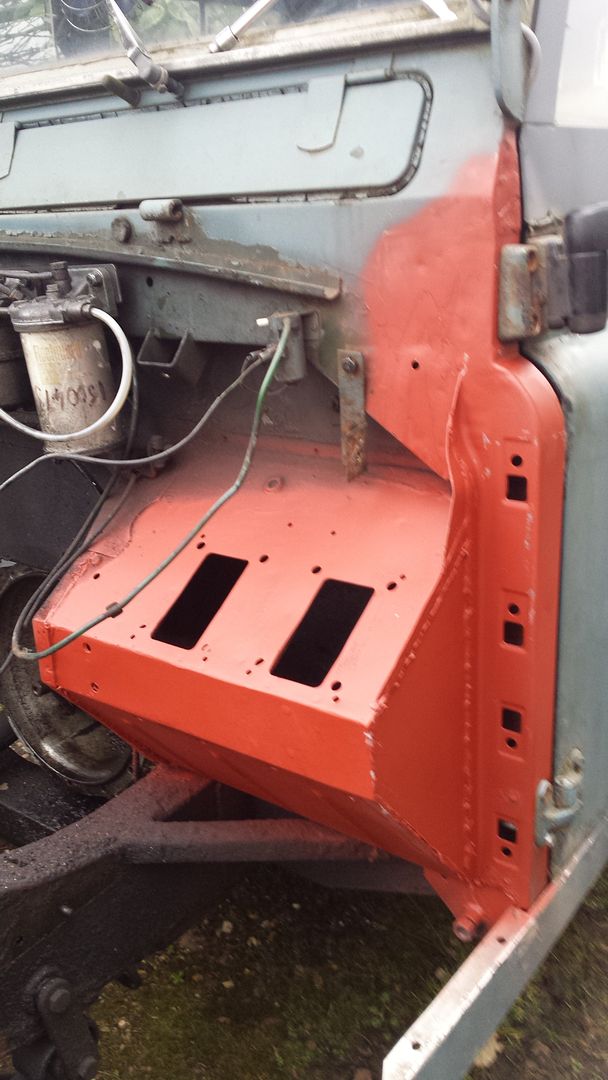

Hi All. My '74 series 3 failed its MOT today - chassis corrosion. The main problems are:

The front spring shackles.

The areas under the front bump stops have holes in

the rear chassis, near the spring hangers.

Can someone give me some advice on how to go about fixing this? I've no experience with welding, but I'm up for learning - is this something I should be attempting or should I be looking for a professional repair?

The good news is everything else passed!

The front spring shackles.

The areas under the front bump stops have holes in

the rear chassis, near the spring hangers.

Can someone give me some advice on how to go about fixing this? I've no experience with welding, but I'm up for learning - is this something I should be attempting or should I be looking for a professional repair?

The good news is everything else passed!