Huddy84

Well-Known Member

- Posts

- 746

- Location

- East Anglia

Saw this on the wolf Tithonus Facebook group earlier and made the connection. I need to do the same as mine is looking manky.

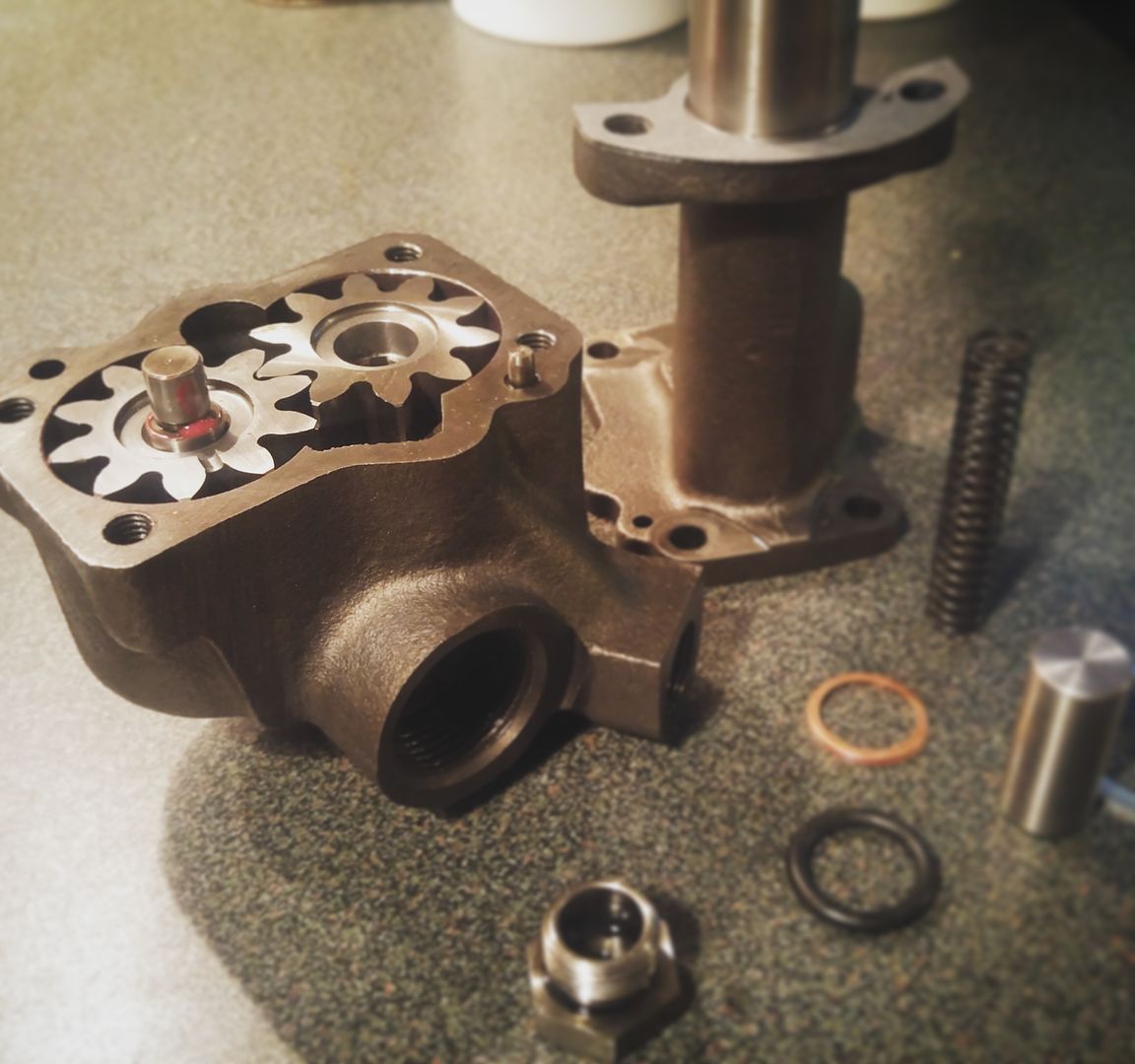

Treated it to some stainless sump bolts too

Welcome To LandyZone, the Land Rover Forums!

Here at LandyZone we have plenty of very knowledgable members so if you have any questions about your Land Rover or just want to connect with other Landy owners, you're in the right place.

Registering is free and easy just click here, we hope to see you on the forums soon!