-

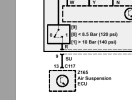

pwood999 replied to the thread P38A EAS question.Yes. Test it first if you can. They are available, but make sure it's the closed above 140psi type. Many are the other way round. I'm guessing you're Estonian ? Put your town name or local region in your profile !!

pwood999 replied to the thread P38A EAS question.Yes. Test it first if you can. They are available, but make sure it's the closed above 140psi type. Many are the other way round. I'm guessing you're Estonian ? Put your town name or local region in your profile !! -

pwood999 replied to the thread Air to Springs.+1 on that Keith. . . . it will be HEVAC motors, compressor clutch, condensor failure, SRS connector problems, heated seat failure, tired water pump, rusting steel brake lines, overheating fusebox, leaking rear-view mirror, etc, etc. ;)

pwood999 replied to the thread Air to Springs.+1 on that Keith. . . . it will be HEVAC motors, compressor clutch, condensor failure, SRS connector problems, heated seat failure, tired water pump, rusting steel brake lines, overheating fusebox, leaking rear-view mirror, etc, etc. ;) -

pwood999 replied to the thread What have you done to your Freelander today.Having got the arms & new bushes on the bench I tend to agree, but as I already have the new bushes will try them frozen first !!

pwood999 replied to the thread What have you done to your Freelander today.Having got the arms & new bushes on the bench I tend to agree, but as I already have the new bushes will try them frozen first !! -

pwood999 reacted to lynall's post in the thread Sport Newbie 🫣 2007 L320 sport 2.7 diesel crank no start. with

pwood999 reacted to lynall's post in the thread Sport Newbie 🫣 2007 L320 sport 2.7 diesel crank no start. withLike.

How had the timing slipped? tensioner/belt etc. How did you lock/tome the crankshaft? Interference engine so anything less than perfect could be bad news. -

pwood999 reacted to Datatek's post in the thread Sport Newbie 🫣 2007 L320 sport 2.7 diesel crank no start. with

pwood999 reacted to Datatek's post in the thread Sport Newbie 🫣 2007 L320 sport 2.7 diesel crank no start. withLike.

Black smoke suggests it's getting fuel. Personally, I would do a compression test because if the timing slipped, there may be valve damage. You could try a squirt of Easy Start to see if it will fire. -

pwood999 replied to the thread P38A EAS question.Yes . . .. are you talking P38 ? For a P38 EAS It should run from zero until 140psi (or thereabouts). Then as pressure drops it starts again around 120psi. If pumping an empty system, it will stop periodically to put air into the airbags...

pwood999 replied to the thread P38A EAS question.Yes . . .. are you talking P38 ? For a P38 EAS It should run from zero until 140psi (or thereabouts). Then as pressure drops it starts again around 120psi. If pumping an empty system, it will stop periodically to put air into the airbags... -

pwood999 replied to the thread Air to Springs.Yet more rubbish statements about cause & effect from you eh ? If your head unit is disconnect, and the speaker amps are still active, then somebody has been messing with the wiring. It will let you down at some point, wherever you happen...

pwood999 replied to the thread Air to Springs.Yet more rubbish statements about cause & effect from you eh ? If your head unit is disconnect, and the speaker amps are still active, then somebody has been messing with the wiring. It will let you down at some point, wherever you happen... -

pwood999 replied to the thread P38A Faked mot exhaust sensor.You need to either Zip the file, or change the filename extension from "csv" to "txt" to upload it.

pwood999 replied to the thread P38A Faked mot exhaust sensor.You need to either Zip the file, or change the filename extension from "csv" to "txt" to upload it. -

pwood999 replied to the thread What have you done to your Freelander today.Standard bushes.

pwood999 replied to the thread What have you done to your Freelander today.Standard bushes. -

pwood999 replied to the thread P38A Faked mot exhaust sensor.Before we digress too far (again) . . . . . @pete12345 even if you cannot open the file, upload the recording here, and we will take a look.

pwood999 replied to the thread P38A Faked mot exhaust sensor.Before we digress too far (again) . . . . . @pete12345 even if you cannot open the file, upload the recording here, and we will take a look. -

pwood999 replied to the thread What have you done to your Freelander today.Removed both rear trailing arms & pressed out the knackered bushes today. That bit wasn't too bad. Replacement bushes are a fraction of a mm larger. Tried chamfering one end, but my press keeps pushing them to one side. Now got them...

pwood999 replied to the thread What have you done to your Freelander today.Removed both rear trailing arms & pressed out the knackered bushes today. That bit wasn't too bad. Replacement bushes are a fraction of a mm larger. Tried chamfering one end, but my press keeps pushing them to one side. Now got them... -

pwood999 replied to the thread P38A Faked mot exhaust sensor.Then they should call it CSCV !!

pwood999 replied to the thread P38A Faked mot exhaust sensor.Then they should call it CSCV !! -

pwood999 replied to the thread P38A Faked mot exhaust sensor.The file should open in either Notepad or Excel. Nanocom CSV format is not quite correct because BBS are still using semi-colons rather than commas to separate the variables.

pwood999 replied to the thread P38A Faked mot exhaust sensor.The file should open in either Notepad or Excel. Nanocom CSV format is not quite correct because BBS are still using semi-colons rather than commas to separate the variables. -

pwood999 replied to the thread P38 diagnostic.Yes. BTW, as well as one of the connectors, it could also be a bulb failure in the cluster. There's two bulbs, & if one fails the other SRS light stays on.

pwood999 replied to the thread P38 diagnostic.Yes. BTW, as well as one of the connectors, it could also be a bulb failure in the cluster. There's two bulbs, & if one fails the other SRS light stays on. -

pwood999 replied to the thread P38 diagnostic.Any Nanocom for P38 should read the SRS system. Only the engine ECU's require unlock codes. If you want to pop up to Langley I could take a quick look. No promises on fixes though. Most likely it's a bad connection on one of the seat...

pwood999 replied to the thread P38 diagnostic.Any Nanocom for P38 should read the SRS system. Only the engine ECU's require unlock codes. If you want to pop up to Langley I could take a quick look. No promises on fixes though. Most likely it's a bad connection on one of the seat... -

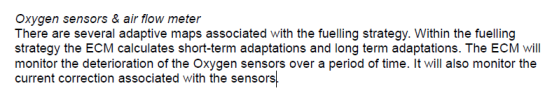

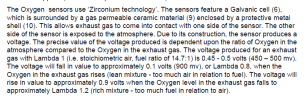

pwood999 replied to the thread P38A Faked mot exhaust sensor.After the engine warms up, do a recording to the SD-Card for the ECU Inputs screen. Then upload the CSV file here so we can look at the live data.

pwood999 replied to the thread P38A Faked mot exhaust sensor.After the engine warms up, do a recording to the SD-Card for the ECU Inputs screen. Then upload the CSV file here so we can look at the live data. -

pwood999 replied to the thread P38A Faked mot exhaust sensor.Also you didn't state your actual issue in the titel or first post ?? Has it failed MOT on emissions, or you have CAT's with no internals & want to adjust the fuelling to pass the MOT ? P38 sensors are Pre-CAT so only tell the ECU what's...

pwood999 replied to the thread P38A Faked mot exhaust sensor.Also you didn't state your actual issue in the titel or first post ?? Has it failed MOT on emissions, or you have CAT's with no internals & want to adjust the fuelling to pass the MOT ? P38 sensors are Pre-CAT so only tell the ECU what's... -

pwood999 replied to the thread L322 GAP IID G3.Can't help with SDD or GAP, but I like this phrase. :)

pwood999 replied to the thread L322 GAP IID G3.Can't help with SDD or GAP, but I like this phrase. :) -

pwood999 replied to the thread P38A Faked mot exhaust sensor.If it's a Thor motor, the O2 sensors should flip between 0V to 1V. If it's not a Thor, then you are using the wrong Nanocom menus !! Long term adaptations should adjust over several drive cycles to get the fueling in the right ballpark. Short...

pwood999 replied to the thread P38A Faked mot exhaust sensor.If it's a Thor motor, the O2 sensors should flip between 0V to 1V. If it's not a Thor, then you are using the wrong Nanocom menus !! Long term adaptations should adjust over several drive cycles to get the fueling in the right ballpark. Short... -

pwood999 replied to the thread Dirty Windscreen.When you've done your nails, pop round & help Roy !!

pwood999 replied to the thread Dirty Windscreen.When you've done your nails, pop round & help Roy !! -

pwood999 replied to the thread What did you do with your Range Rover today.Check if the existing O2 sensors are working first. Although it usually recommended not to clean them, I've had good results in the past using carb cleaner on O2 sensors. Make sure the connectors are properly clean, as their position either...

pwood999 replied to the thread What did you do with your Range Rover today.Check if the existing O2 sensors are working first. Although it usually recommended not to clean them, I've had good results in the past using carb cleaner on O2 sensors. Make sure the connectors are properly clean, as their position either... -

pwood999 reacted to andyfreelandy's post in the thread Freelander 1 Headlining Replacement - completed with

pwood999 reacted to andyfreelandy's post in the thread Freelander 1 Headlining Replacement - completed withLike.

Good question !! Cut to fit but can measure and will post. -

pwood999 replied to the thread P38A Complete failure of window regulator and mirror (switch pack).12V (batt +) on pin-1 & 0V (batt -) on pin-3 briefly wathcing which way the window goes. If it tries to go down, reverse the wires. The other pins are used by the outstation & BECM for blockage / trap detection, so you don't need them for...

pwood999 replied to the thread P38A Complete failure of window regulator and mirror (switch pack).12V (batt +) on pin-1 & 0V (batt -) on pin-3 briefly wathcing which way the window goes. If it tries to go down, reverse the wires. The other pins are used by the outstation & BECM for blockage / trap detection, so you don't need them for... -

pwood999 replied to the thread P38A Complete failure of window regulator and mirror (switch pack).You don't. Simply connect 12V to the motor until the window reaches the top & disconnect the wires. Start by applying 12V for 1-2 seconds & see which way the window moves. Do it in stages makinbg sure you disconnect at the top to avoid...

pwood999 replied to the thread P38A Complete failure of window regulator and mirror (switch pack).You don't. Simply connect 12V to the motor until the window reaches the top & disconnect the wires. Start by applying 12V for 1-2 seconds & see which way the window moves. Do it in stages makinbg sure you disconnect at the top to avoid... -

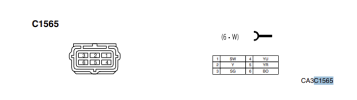

pwood999 replied to the thread P38A Complete failure of window regulator and mirror (switch pack).If you search for the connector number it shows you. C1565 on page 590 of that link you posted. SW & SG are the wire colours (page 14) if you need to identify the pins.

pwood999 replied to the thread P38A Complete failure of window regulator and mirror (switch pack).If you search for the connector number it shows you. C1565 on page 590 of that link you posted. SW & SG are the wire colours (page 14) if you need to identify the pins. -

pwood999 replied to the thread Freelander 1 Headlining Replacement - completed.What size was the skirting & wood blocks ?

pwood999 replied to the thread Freelander 1 Headlining Replacement - completed.What size was the skirting & wood blocks ?