Hard-Drive

Active Member

- Posts

- 359

- Location

- Rugby

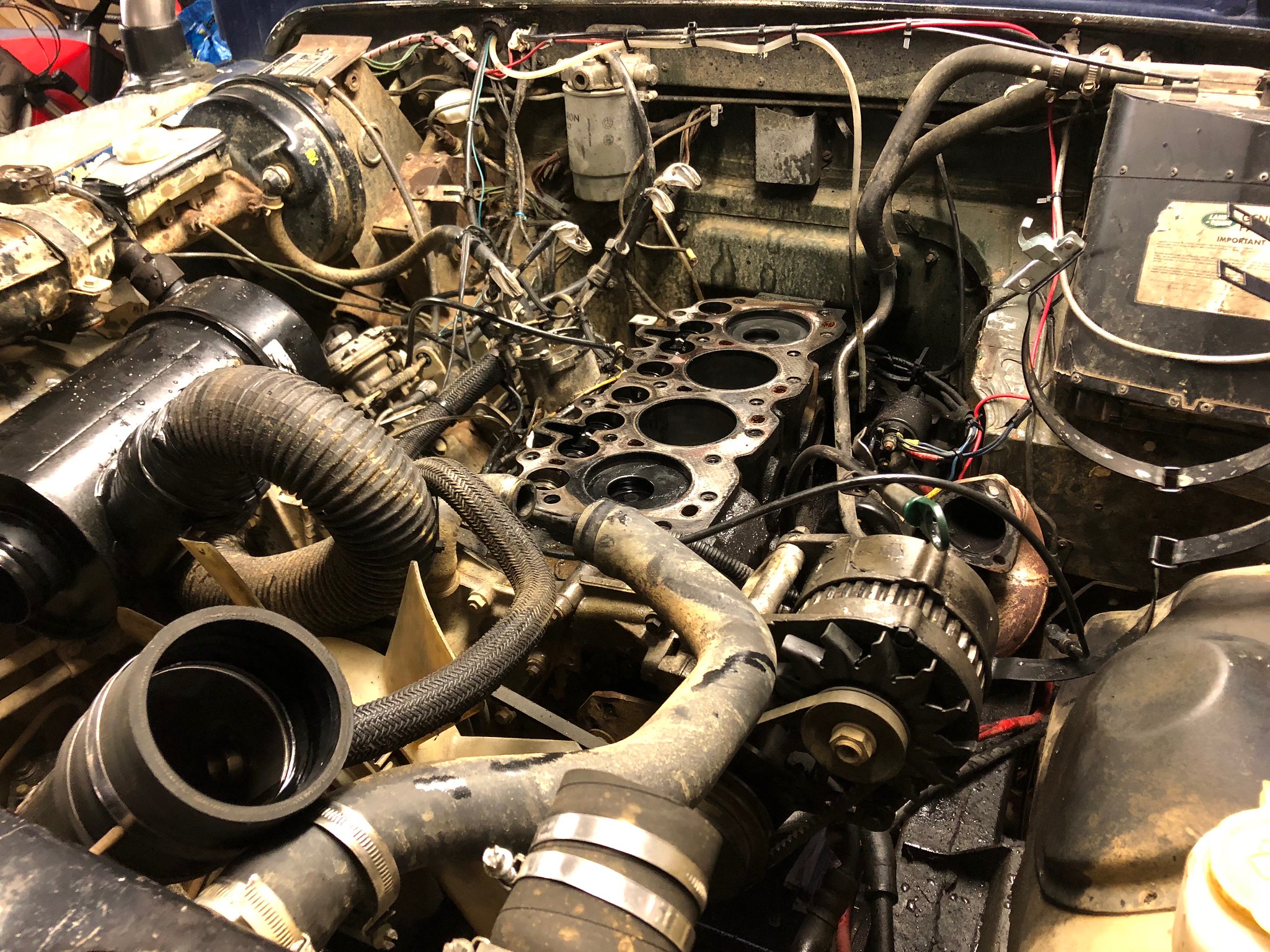

My Landy has been faultless recently, however suddenly today I have big problems. It's a 1986 110 that's been converted to a Disco 200Tdi. Conversion has been done "properly" with full Steve Parker bits on the intake and exhaust side. Always pulled like a train, if a little smoky under load.

Today I started it and it seemed a bit rough at tickover the moment it fired, with a noticeable vibration. Drove off, thinking nothing of it, however I noticed very heavy smoking under accelerartion (more black than blue, but definitely a smell of burning oil)

I nursed it home carefully keeping revs and boost low and it made it. I have digital gauges for water temp, oil temp, oil pressure (as well as standard fit oil light) and turbo boost. All stayed normal on the way home. It was a little lumpy, and although I was being very gentle, there was still power there by the feels of things.

Under the bonnet it's thrown a lot of oil out of the dipstick. There's also a lot of oil in the pipe that runs from the air filter to the turbo. There's a lot of oil everywhere and very little on the dipstick. Water level looks a bit low, although may have been like that before. I can't see any evidence of oil and water mixing...header tank is clear and no mayo under the oil filler cap. Cap was very smoky when I took it off.

My 110 has always like to "mark it's territory" in the dripping oil department, but this is a whole new thing, there's oil all over the alternator, chassis, wheel arch, everywhere. Something has obviously just let go in a big way overnight. I know I should check the crankcase filter on the side of the head, however if that was blocked it would cause oil spray from the dipstick, but would it cause the excessive smoking and rough running?

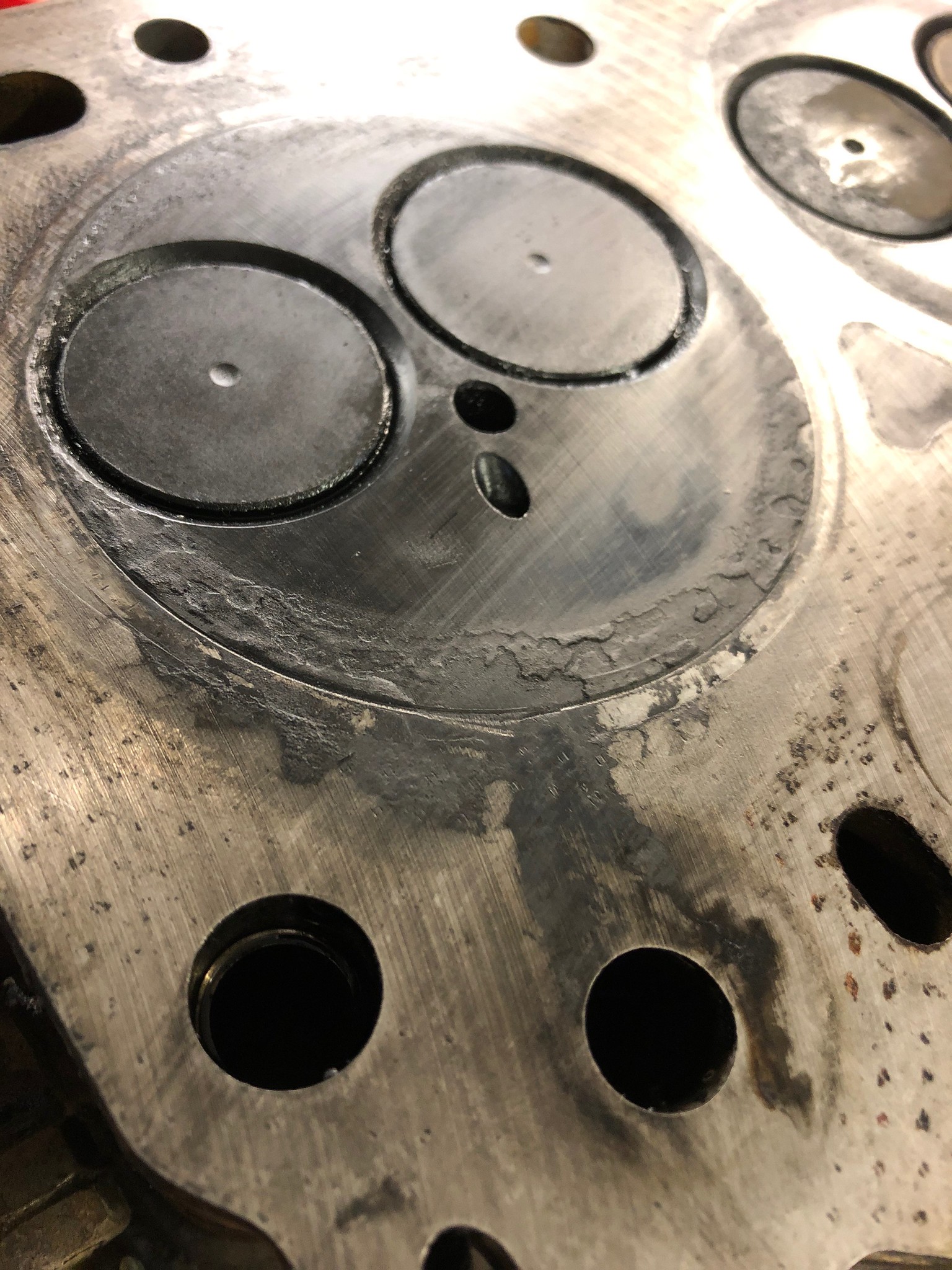

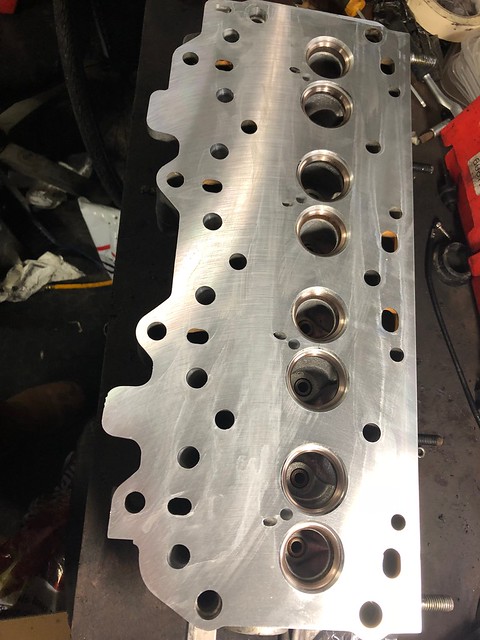

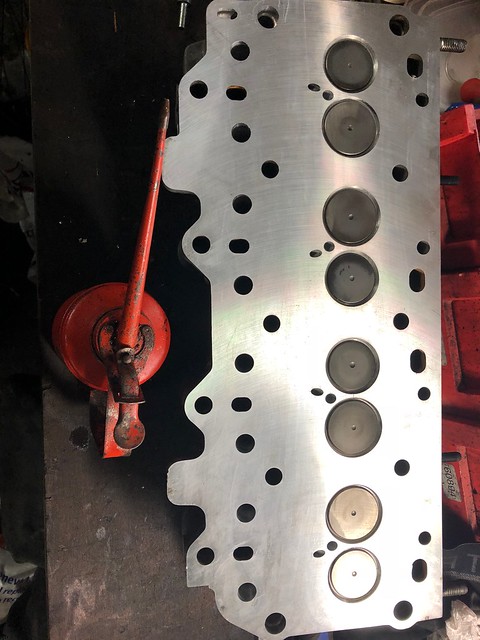

Head gasket? Knackered piston rings (suddenly?) Turbo?

Help...needless to say I'm absolutely gutted...any help or pointers would be much appreciated.

Thanks

Today I started it and it seemed a bit rough at tickover the moment it fired, with a noticeable vibration. Drove off, thinking nothing of it, however I noticed very heavy smoking under accelerartion (more black than blue, but definitely a smell of burning oil)

I nursed it home carefully keeping revs and boost low and it made it. I have digital gauges for water temp, oil temp, oil pressure (as well as standard fit oil light) and turbo boost. All stayed normal on the way home. It was a little lumpy, and although I was being very gentle, there was still power there by the feels of things.

Under the bonnet it's thrown a lot of oil out of the dipstick. There's also a lot of oil in the pipe that runs from the air filter to the turbo. There's a lot of oil everywhere and very little on the dipstick. Water level looks a bit low, although may have been like that before. I can't see any evidence of oil and water mixing...header tank is clear and no mayo under the oil filler cap. Cap was very smoky when I took it off.

My 110 has always like to "mark it's territory" in the dripping oil department, but this is a whole new thing, there's oil all over the alternator, chassis, wheel arch, everywhere. Something has obviously just let go in a big way overnight. I know I should check the crankcase filter on the side of the head, however if that was blocked it would cause oil spray from the dipstick, but would it cause the excessive smoking and rough running?

Head gasket? Knackered piston rings (suddenly?) Turbo?

Help...needless to say I'm absolutely gutted...any help or pointers would be much appreciated.

Thanks