Moosekeeper

Member

- Posts

- 33

- Location

- Aintree, Liverpool

Just bought my first ever diesel - Freelander 1 TD4 2004. I had two brand new Durite gauges left over from cancelled projects and was hoping to fit them to my Freelander to cover up the two holes on the top of the dash apparently for cans of Coke! Seriously a voltmeter can save your bacon if your battery is dying on a dark, cold night with everthing on electrically and oil pressure is, of course, a good monitor of an engine's health. The only bit I didn't have was an M12 x 1.5 T piece and I got one easily enough on Ebay. I don't have a ramp or pit at home so I was going to get my local garage to fit the T piece and sender, me doing the rest of the installation.

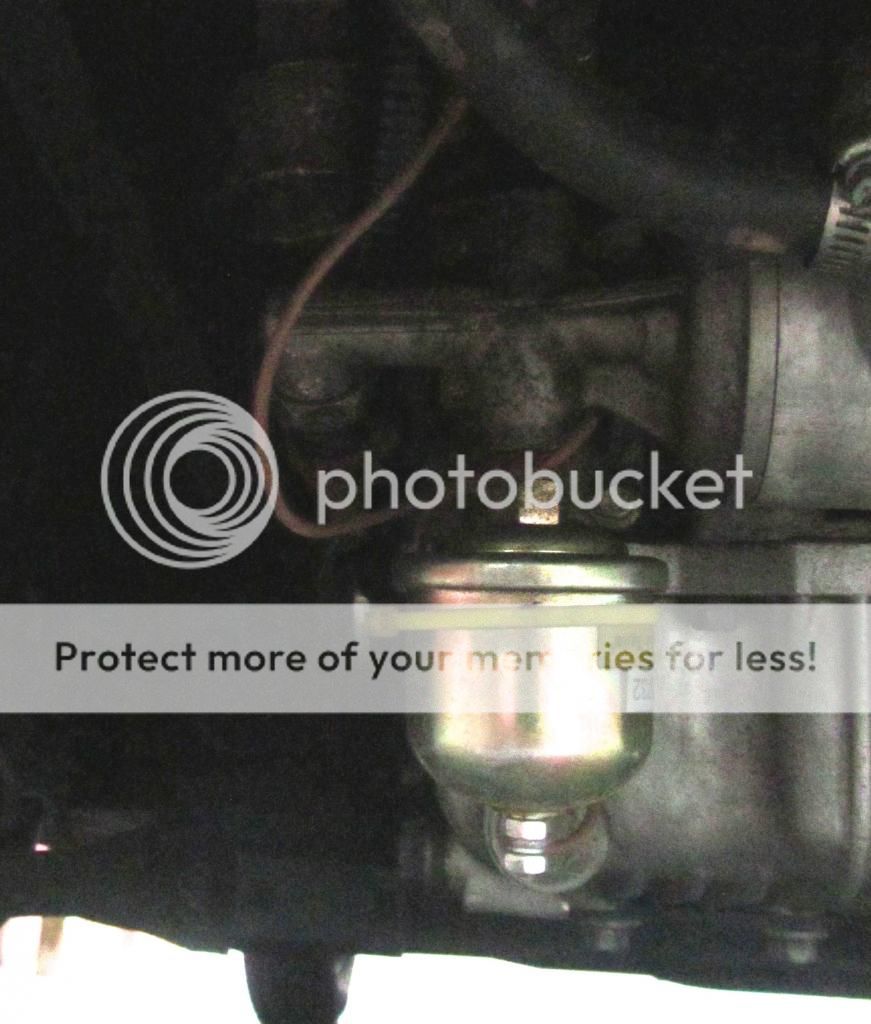

However the Haynes manual has me worried. It describes fitting a new oil pressure switch as requiring removal of the starter motor. And removal of the starter motor requiring removal of the battery! Doable I suppose but isn't there an easier way? I thought access might be gained by removing the engine undertray or front "skid plate" whatever it's called. Is the location of the switch so awkward that all this dismatling is necessary? Any crafty ways of doing this (or should I just buy two cans of Coke to fill those holes?!)

However the Haynes manual has me worried. It describes fitting a new oil pressure switch as requiring removal of the starter motor. And removal of the starter motor requiring removal of the battery! Doable I suppose but isn't there an easier way? I thought access might be gained by removing the engine undertray or front "skid plate" whatever it's called. Is the location of the switch so awkward that all this dismatling is necessary? Any crafty ways of doing this (or should I just buy two cans of Coke to fill those holes?!)