As some may have followed I've just started chopping and welding. I have the bilt hamber electrox 90 zinc primer. My initial thoughts were to flappy wheel my welds and surrounding area to get all clean, panel wipe or similar then prime, seal then my epoxy mastik. Is this the correct order as on the lr it seams the seam sealer has been applied prior to any paint I.e to bare metal? I can't guarantee a like new surface so thought I was better off primer first as it has anti corrosive properties. Cheers

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Sealer before or after zinc primer?

- Thread starter resto_d1

- Start date

This site contains affiliate links for which LandyZone may be compensated if you make a purchase.

Flossie

Well-Known Member

- Posts

- 10,624

- Location

- Shropshire

Paint then seal but prime sealer before top coating.

Flossie

Well-Known Member

- Posts

- 10,624

- Location

- Shropshire

Not sure if my post was clear

But yes, do what you said in your post.

But yes, do what you said in your post.

LR are not renowned for their rust protection. I once crawled under a brand new Defender in a showroom and it had the first indications of rust on the chassis.As some may have followed I've just started chopping and welding. I have the bilt hamber electrox 90 zinc primer. My initial thoughts were to flappy wheel my welds and surrounding area to get all clean, panel wipe or similar then prime, seal then my epoxy mastik. Is this the correct order as on the lr it seams the seam sealer has been applied prior to any paint I.e to bare metal? I can't guarantee a like new surface so thought I was better off primer first as it has anti corrosive properties. Cheers

As some may have followed I've just started chopping and welding. I have the bilt hamber electrox 90 zinc primer. My initial thoughts were to flappy wheel my welds and surrounding area to get all clean, panel wipe or similar then prime, seal then my epoxy mastik. Is this the correct order as on the lr it seams the seam sealer has been applied prior to any paint I.e to bare metal? I can't guarantee a like new surface so thought I was better off primer first as it has anti corrosive properties. Cheers

IMHO, only seal where essential - I don't use sealer unless it's a really exposed area like wheel arches... I prefer to let a cavity wax ( BH Dynax S-50 ) do its stuff and penetrate a seam... and retreat the seam regularly.....

Seams which need sealing I would definitely prime beforehand - I either use brake cleaner or panel wipe ( whichever is cheaper ) to degrease, and then etch primer...

I'm a big fan of BH products, and have used them for many years with great results. from what I have seen, Dinitrol stuff is comparable

I might suggest that LR's original "corrosion protection", er, "efforts" would be better termed "corrosion promotion", after all, they want you to buy a new one .....

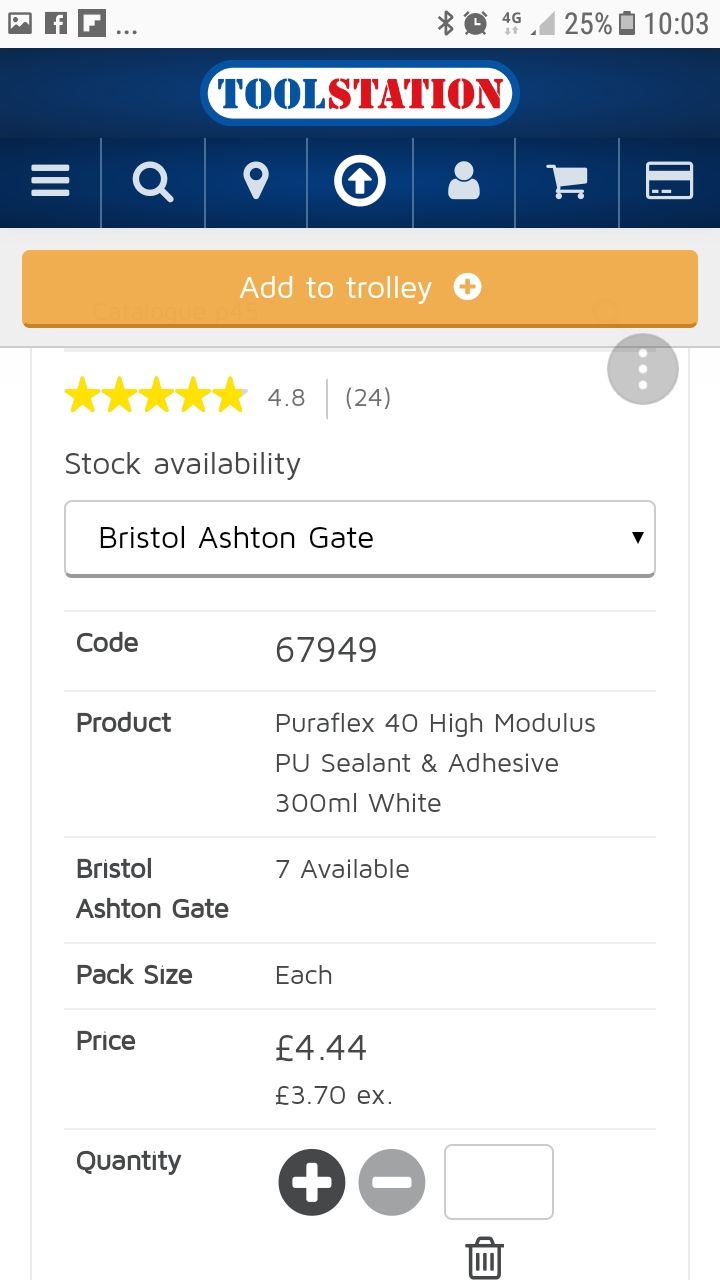

Thanks. It's primarily for over my welds at the moment so I just wanted to seal off the weld. I too am a big fan of their stuff. I haven't cracked open the epoxy yet - not far enough into repairs. Will be at the weekend though fingers crossed. I was planning to get dynax in everywhere which is the bh cavity wax. I just bought some paintable pu sealant for it

Suggest you read the relevant Technical Data sheets for your selected product.

This one for 3M Polyurethane seam sealer advises to apply to bare metal.

https://www.3m.co.uk/3M/en_GB/compa...13+8709338+8711017+8711413+3293211317&rt=rud#

Apply directly to bare steel, or use as a weld-through sealer. Must be done while the product is wet (within 35 minutes of application).

This one for 3M Polyurethane seam sealer advises to apply to bare metal.

https://www.3m.co.uk/3M/en_GB/compa...13+8709338+8711017+8711413+3293211317&rt=rud#

Apply directly to bare steel, or use as a weld-through sealer. Must be done while the product is wet (within 35 minutes of application).

Just painted it all up with electrox! Where I'm welding in sections It's probably easier to paint as I go to prevent rust creeping back in and more surface prep. I guess anything is better than the bran flakes that the sections have replaced!