jai_landrover

Well-Known Member

- Posts

- 13,392

- Location

- Luton

Right I have done many mods to my 90 to improve its off road ability and I refuse to add anything like a drop plate or anything that hangs down from the rear x member that can get hung up. I need to be able to tow from a ball at a sensible height every now and then but do not want to add anything permenant.

So.....

The requiremnent:

To have a totally removable tow hitch that can be carried in the back of the 90 when not in use and can be quickly attached for towing normal 50mm ball type trailers at a sensible useable height.

I think somthing that would attach to my nato hotch and anchor securly under to the chassis rails is in order. I have seen various and each have their own design advantages and disadvantages. I chose to build my own but sticking to the rule that it should be of a good mechanical fit and any welds are to be used to hold metal together and not to used solely to support anything keeping strength to a max. Overengineering is a Family thing.

Turnig down some solid bar stock:

Mocking up the sides and plate:

Drilling the holes in the angle for the stepped machined down weight bearing bar ends to be inserted and welded in place:

Quick check on the dosco to make sure it all works before welding it up:

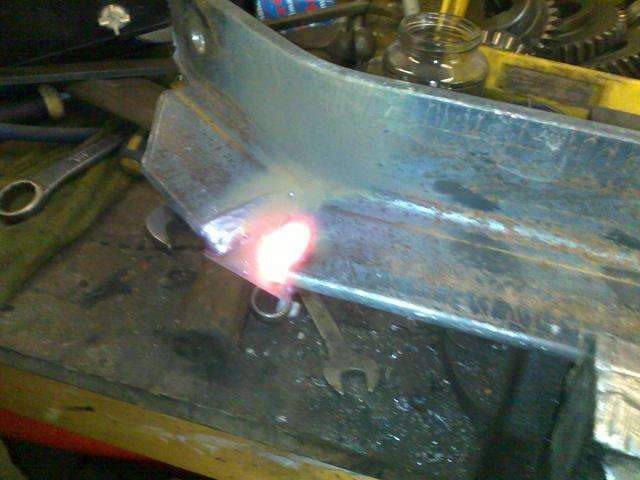

Welding up the ends and internals mating the bar to the Angle sides:

Mocking it up ready for the bottom stays:

Uploaded with ImageShack.us

Bit dark to continue any more today. Sorry for the bad pic but I will hopefully have the rear stays sorted tomorrow night or if not Saturday at some point bit of a clean up and paint job should be good.

Comments and Ideas welcome.

Must be said Big thankyou to Spitfiremk1uk for use of his lathe, welding ability and the beasty drill. Cheers Bro!

So.....

The requiremnent:

To have a totally removable tow hitch that can be carried in the back of the 90 when not in use and can be quickly attached for towing normal 50mm ball type trailers at a sensible useable height.

I think somthing that would attach to my nato hotch and anchor securly under to the chassis rails is in order. I have seen various and each have their own design advantages and disadvantages. I chose to build my own but sticking to the rule that it should be of a good mechanical fit and any welds are to be used to hold metal together and not to used solely to support anything keeping strength to a max. Overengineering is a Family thing.

Turnig down some solid bar stock:

Mocking up the sides and plate:

Drilling the holes in the angle for the stepped machined down weight bearing bar ends to be inserted and welded in place:

Quick check on the dosco to make sure it all works before welding it up:

Welding up the ends and internals mating the bar to the Angle sides:

Mocking it up ready for the bottom stays:

Uploaded with ImageShack.us

Bit dark to continue any more today. Sorry for the bad pic but I will hopefully have the rear stays sorted tomorrow night or if not Saturday at some point bit of a clean up and paint job should be good.

Comments and Ideas welcome.

Must be said Big thankyou to Spitfiremk1uk for use of his lathe, welding ability and the beasty drill. Cheers Bro!