Defender-Sam

New Member

- Posts

- 358

- Location

- Burton Upon Trent

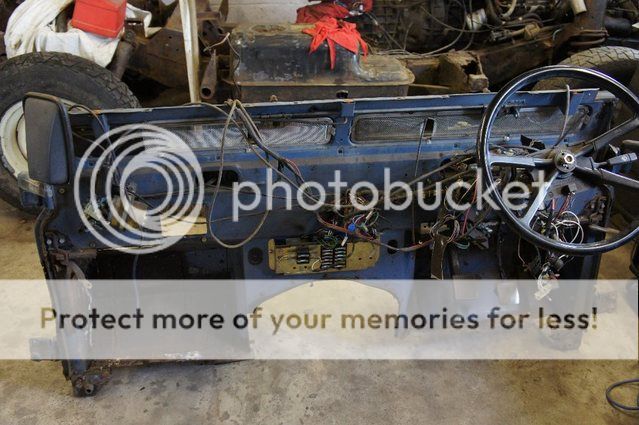

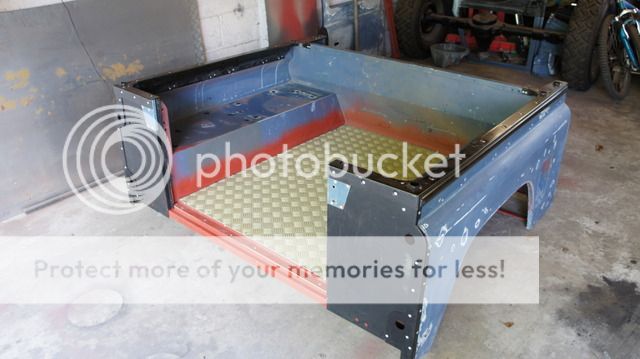

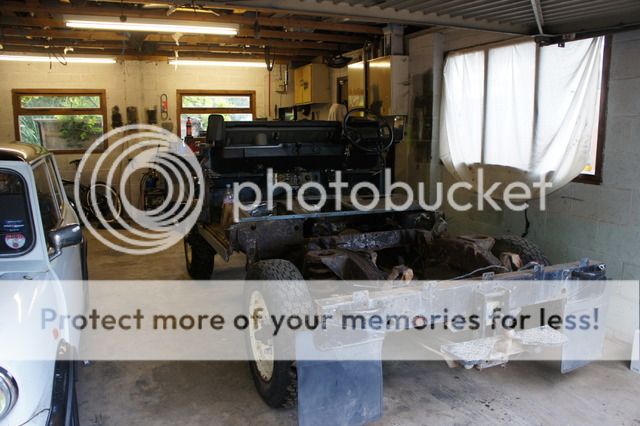

How do people, thought i would start a thread for my 90 project, it was brought around this time last year and i have been working on it in my spare time. it turned out to be a fairly big project requiring a new chassis (richards) due monday and fairly extensive work mechanical wise and body.... I will start with a few posts of the work i have done so far

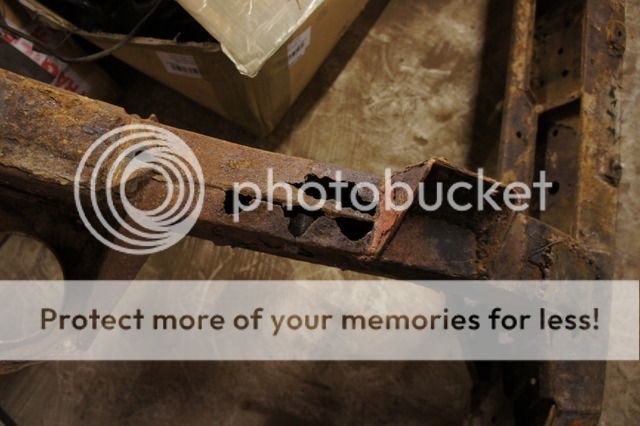

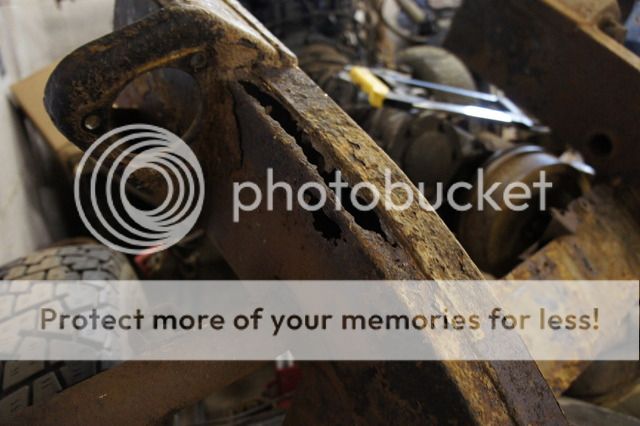

doesn't look to bad?

oops spoke too soon!

thanks for looking. Sam

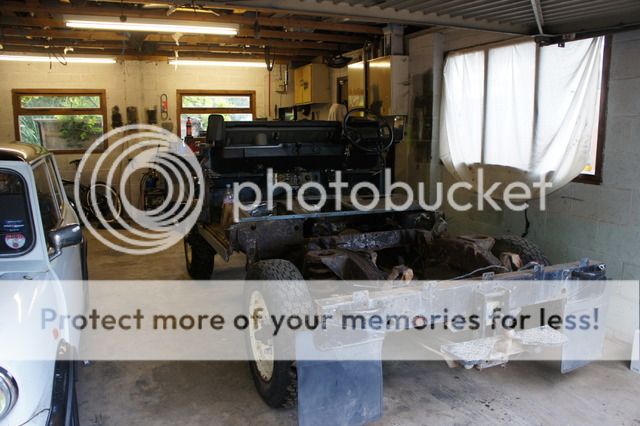

doesn't look to bad?

oops spoke too soon!

thanks for looking. Sam