Hippo

Lord Hippo

- Posts

- 51,803

I have a knocking sound coming from the near side front I think. It happens when I go over drains, bumps, pull away and brake, from memory. When driving through a river it goes away afterwards. So this made me think, is was a bush. Noise has been there for over a year (don't do many miles) and even the mot chap couldn't get it to show up. But it has got worse in the last 2 weeks. Going off road last weekend made it a bit worse, so now it's frequent enough for me to find, or so I thought.

Had a go at pulling/pushing the drive shafts. Bit of play in them both, in both sections, but not much. Not sure if that's how they are, or they're starting to wear. 1 of the anti roll bar clamp things looks worse than the other, so I'll change them both. Have pushed un pulled about with wheels etc. Also a length of wood to lever it underneath to move it up un down to get the suspension moving. Noise went away after I removed the sump guard before all this, so now it's gone back a bit tighter. Noise has now gone.

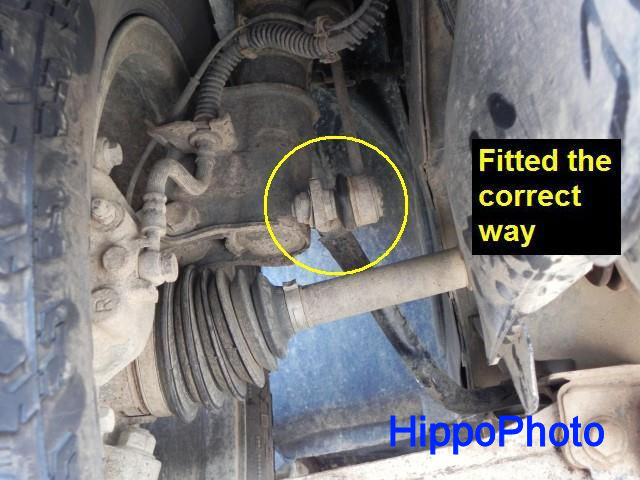

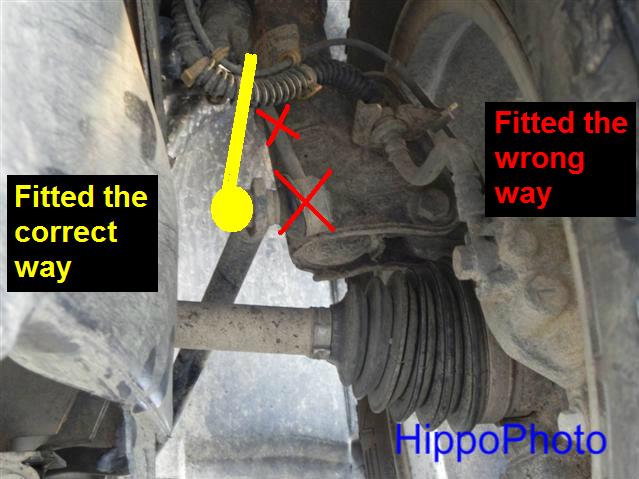

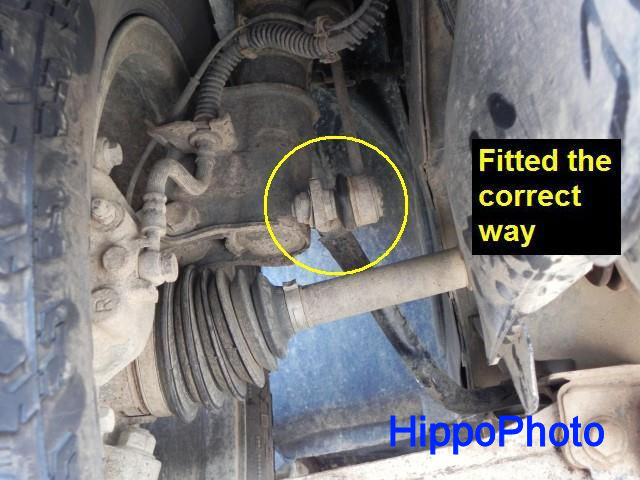

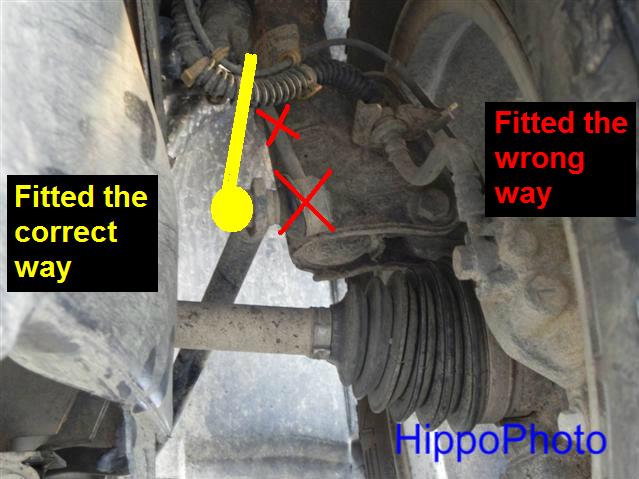

However, when looking at the drop links I noticed one faces the wheel, and the other doesn't. Is that correct, and is that the same on your Freelander? Mines a 2001 v6. Looks like the off side one has been hitting the metal next to it.

Edit: to confirm - you should fit the nuts on the wheel side.

Off side

DSCN2030 znD6zhg

Near side

DSCN2027 KOpNHDW

Had a go at pulling/pushing the drive shafts. Bit of play in them both, in both sections, but not much. Not sure if that's how they are, or they're starting to wear. 1 of the anti roll bar clamp things looks worse than the other, so I'll change them both. Have pushed un pulled about with wheels etc. Also a length of wood to lever it underneath to move it up un down to get the suspension moving. Noise went away after I removed the sump guard before all this, so now it's gone back a bit tighter. Noise has now gone.

However, when looking at the drop links I noticed one faces the wheel, and the other doesn't. Is that correct, and is that the same on your Freelander? Mines a 2001 v6. Looks like the off side one has been hitting the metal next to it.

Edit: to confirm - you should fit the nuts on the wheel side.

Off side

DSCN2030 znD6zhg

Near side

DSCN2027 KOpNHDW

Last edited: