Part one -At last the thread you've all been waiting for (probably), the rebuild of my recon 2.5 na diesel.

A quick review - If you want to play along at home, first you need to spend £2000 on a recon cylinder head and 3/4 engine from ACR landrover, find no compression and the camshaft falling out, send it back then find no compression again and an oil leak then decide to strip the motor and find automotive component remanufacturing wash their hands of it because of the "unauthorised" strip down.

.

.

.

Done that? Stopped bursting into tears occasionally yet? Got the wife to talk to you yet?

No? Me neither.

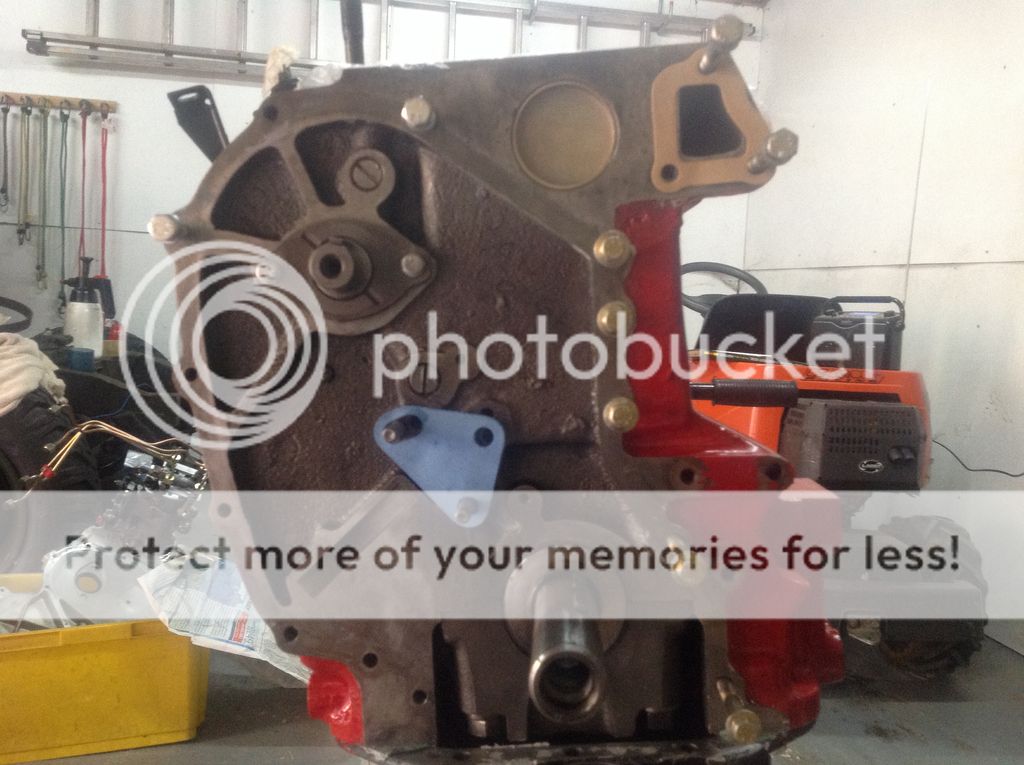

The first photo shows the crank, rods and flywheel. These have been balanced, you should be able to see extra holes in the crank webs and grinding on the small and big ends of the rods.

According to the balancers, the crank was the worse 4 cylinder they've ever done. Normally they take 2-3g off the two planes. This crank was 13g and 6g. Don't know if the crank is genuine or pattern.

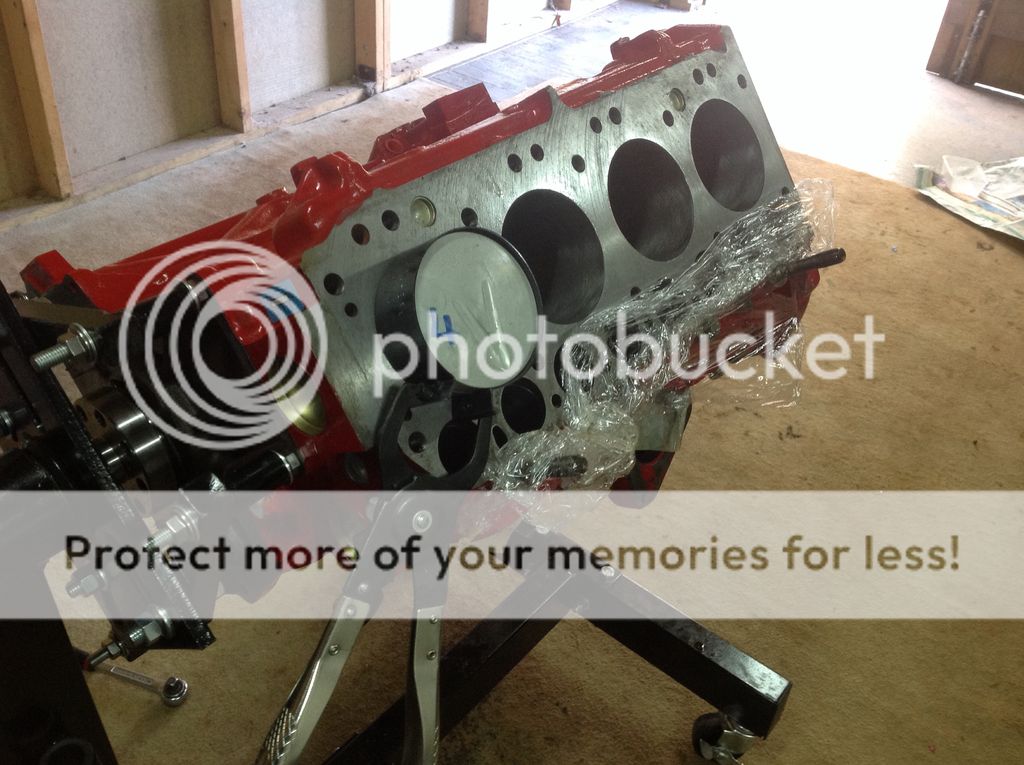

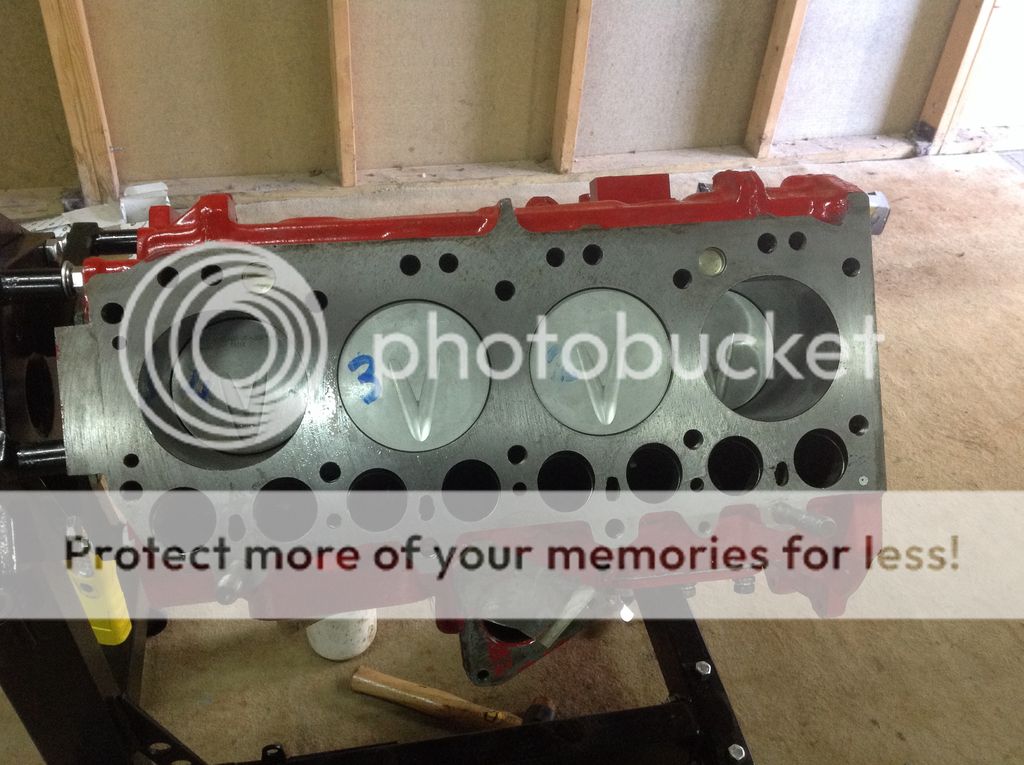

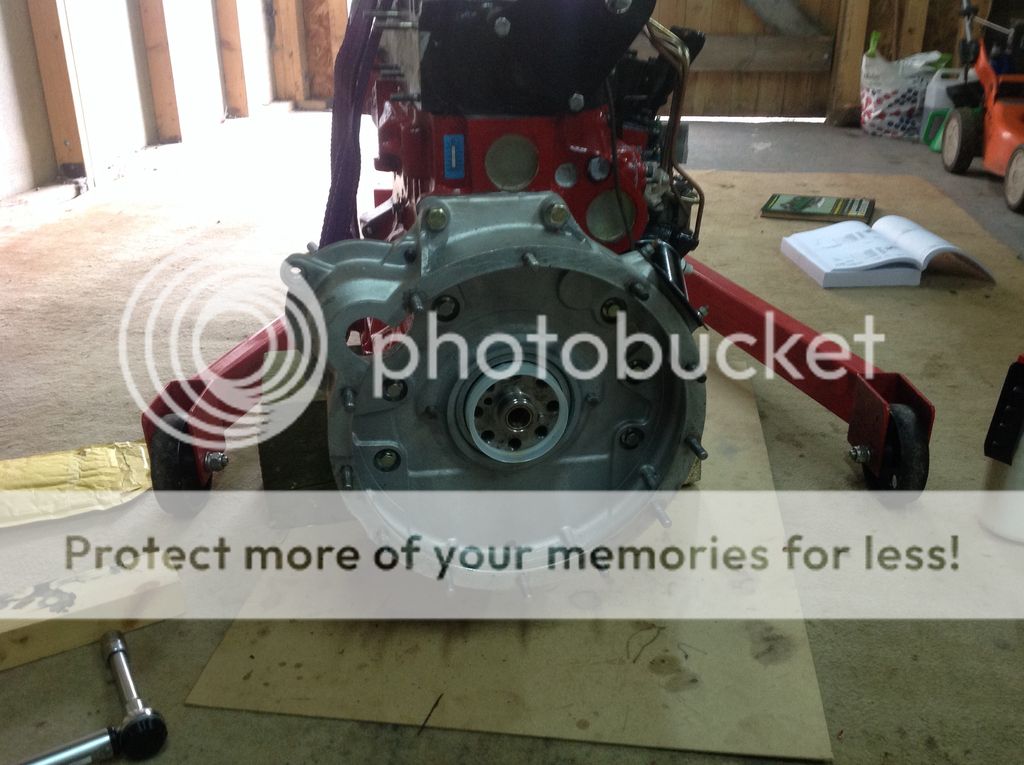

Second photo is the block on a stand (cling film is to preserve freshness). I tried dismantling the motor on a pallet stand, didn't really work so I bought an engine stand (sgs £80). I would urge anyone contemplating this to get one. The bare block is only barely liftable and I have the powerful physique of two fully grown mountain gorillas. Once the crank is in, it's not really practical. On the engine, it can be rotated and even If I sell it straight after, it's still cheaper than hiring one.

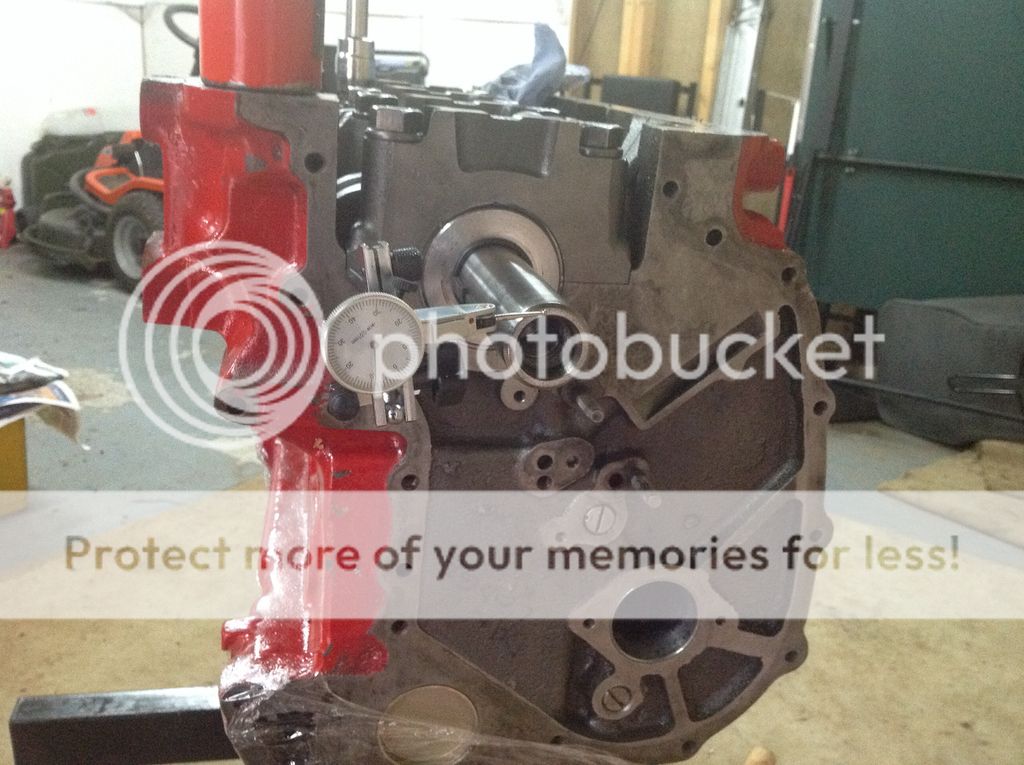

Next fitting the crank and bearings - what could possibly go wrong?

A quick review - If you want to play along at home, first you need to spend £2000 on a recon cylinder head and 3/4 engine from ACR landrover, find no compression and the camshaft falling out, send it back then find no compression again and an oil leak then decide to strip the motor and find automotive component remanufacturing wash their hands of it because of the "unauthorised" strip down.

.

.

.

Done that? Stopped bursting into tears occasionally yet? Got the wife to talk to you yet?

No? Me neither.

The first photo shows the crank, rods and flywheel. These have been balanced, you should be able to see extra holes in the crank webs and grinding on the small and big ends of the rods.

According to the balancers, the crank was the worse 4 cylinder they've ever done. Normally they take 2-3g off the two planes. This crank was 13g and 6g. Don't know if the crank is genuine or pattern.

Second photo is the block on a stand (cling film is to preserve freshness). I tried dismantling the motor on a pallet stand, didn't really work so I bought an engine stand (sgs £80). I would urge anyone contemplating this to get one. The bare block is only barely liftable and I have the powerful physique of two fully grown mountain gorillas. Once the crank is in, it's not really practical. On the engine, it can be rotated and even If I sell it straight after, it's still cheaper than hiring one.

Next fitting the crank and bearings - what could possibly go wrong?

Last edited: