farmershort

Well-Known Member

- Posts

- 1,067

- Location

- West Berkshire

Hi All,

As some will know already, I've recently bought my donor vehicle, and have been busy planning and arranging the various rebuild components.

Currently I have a 3.9 serp v8 engine on it's way to John Eales for rebuild, and a Richards galv chassis on order.

John will be turning the old 3.9 into a 4.6 with a few mods. Output is estimated at around 270bhp.

I have spoken with Aschrofts about the gearbox & transfer box refurb. As soon as I manage to secure a v8 R380 bellhousing, I will be sending them off for refurb & strengthening.

I'm also chatting with exmoor trim about the interior styling - but this is probably a long way down the road.

Well, here's the donor... A 1998 110 defender 300tdi:

There was the faded signs of a telephone number on one of the doors, so I thought I'd chance it and give them a ring to see if anyone knew it's history. After a couple of days wait, a very nice chap got back to me and said that he used to own it. It had been owned by his company over the last 6 or so years. They only sold it 8 months previous to me buying. One of the best bits of info that came out of the phone call as that this 110 had a brand new 300tdi engine just 72,000 miles ago!!!! Offers on a postcard!

Rough plan for the rebuild is thus:

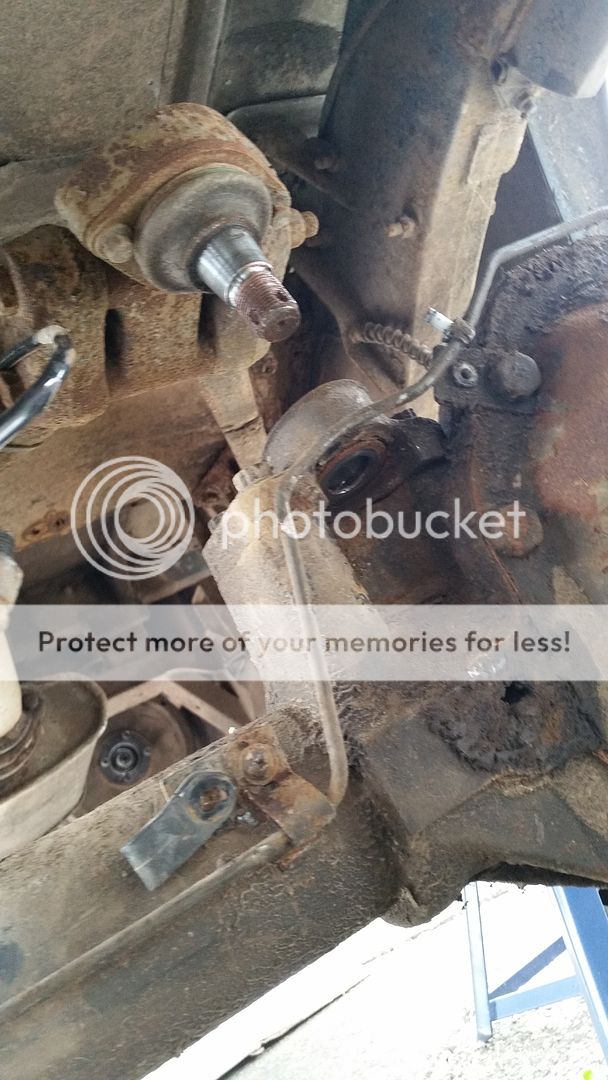

get landy jacked up onto stands, and remove the wheels.

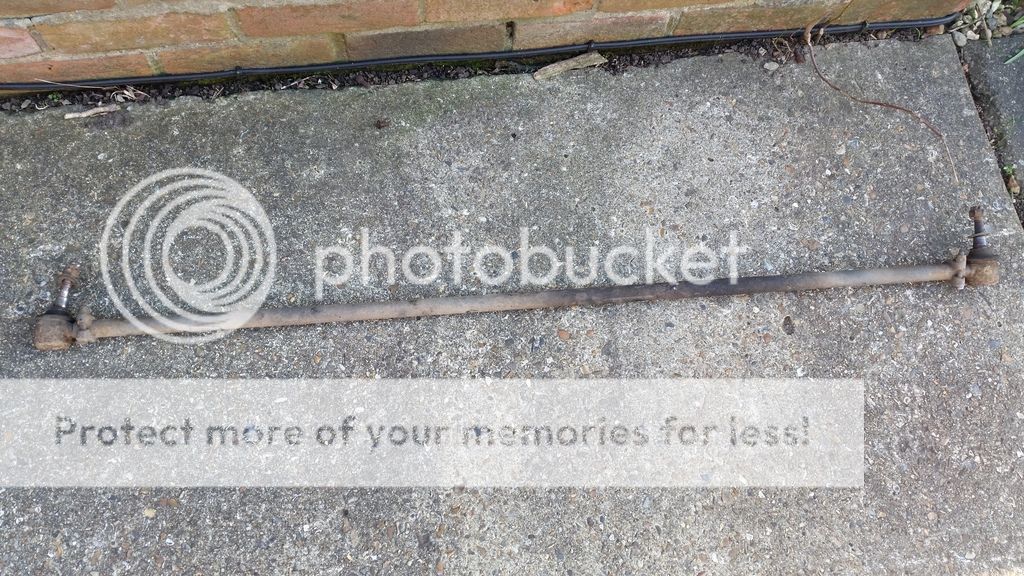

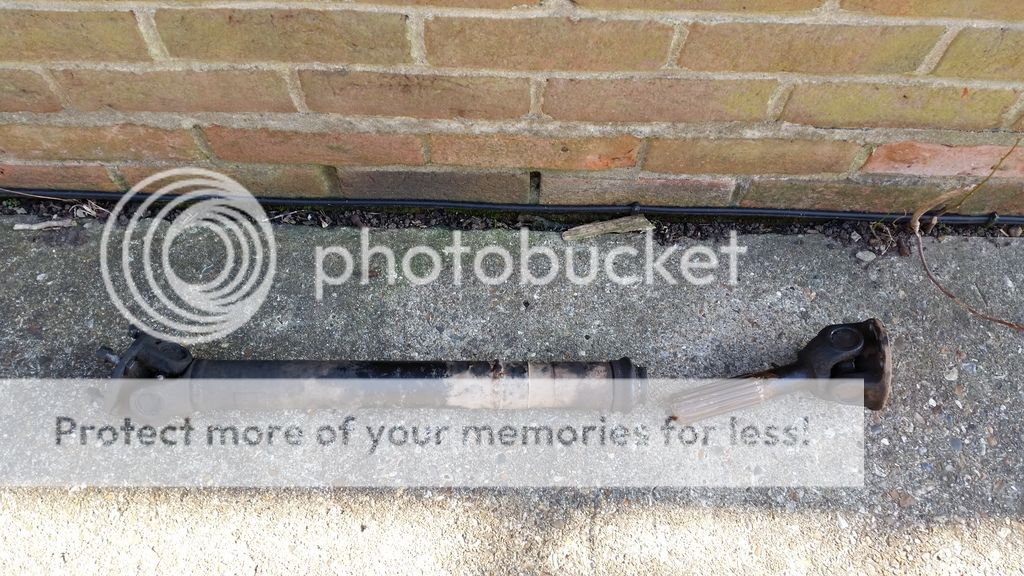

Remove radius arms and axles (and associated) and strip for shot blasting

clean & paint refurbed axles and other metal work

rebuild diffs

.

.

.

.

That's as far as I've got in my head so far.

These are the things I know I need to source:

v8 R380 bellhousing

Roof in good condition

new rear door

If anyone has any great time-saving hints, they'd be most welcomed. I'm keen to avoid the silly mistakes that generally lead to having to re-do a job.

Thanks

Adam

p.s. I'm also doing a blog about the rebuild, so I'll try and get the blog posts to feed into this thread - blog here: http://farmershort.co.uk/blog

As some will know already, I've recently bought my donor vehicle, and have been busy planning and arranging the various rebuild components.

Currently I have a 3.9 serp v8 engine on it's way to John Eales for rebuild, and a Richards galv chassis on order.

John will be turning the old 3.9 into a 4.6 with a few mods. Output is estimated at around 270bhp.

I have spoken with Aschrofts about the gearbox & transfer box refurb. As soon as I manage to secure a v8 R380 bellhousing, I will be sending them off for refurb & strengthening.

I'm also chatting with exmoor trim about the interior styling - but this is probably a long way down the road.

Well, here's the donor... A 1998 110 defender 300tdi:

There was the faded signs of a telephone number on one of the doors, so I thought I'd chance it and give them a ring to see if anyone knew it's history. After a couple of days wait, a very nice chap got back to me and said that he used to own it. It had been owned by his company over the last 6 or so years. They only sold it 8 months previous to me buying. One of the best bits of info that came out of the phone call as that this 110 had a brand new 300tdi engine just 72,000 miles ago!!!! Offers on a postcard!

Rough plan for the rebuild is thus:

get landy jacked up onto stands, and remove the wheels.

Remove radius arms and axles (and associated) and strip for shot blasting

clean & paint refurbed axles and other metal work

rebuild diffs

.

.

.

.

That's as far as I've got in my head so far.

These are the things I know I need to source:

v8 R380 bellhousing

Roof in good condition

new rear door

If anyone has any great time-saving hints, they'd be most welcomed. I'm keen to avoid the silly mistakes that generally lead to having to re-do a job.

Thanks

Adam

p.s. I'm also doing a blog about the rebuild, so I'll try and get the blog posts to feed into this thread - blog here: http://farmershort.co.uk/blog

Last edited: