TrilloThrillo110

Active Member

- Posts

- 157

- Location

- Christchurch, New Zealand

Update:

Hey guys, I'm new to this forum, but definitely not new to Landies.

I've been into off roading and Land Rovers since I was 2 years old, and now that I'm fourteen, I've got one. I bought this 1994 Honda Crossroad (essentially a Disco 1) last October. Since buying it I've put the 'Rego' on hold and parked it up, due to not having the time or funds to run it. So here it is....

Not bad for $2000 (£1000)!!!!

It has the 3.9 V8 and 183,000 kms on the clock. A previous owner (who I actually know) fitted most the mods to it so I know everythings been done right. The flares cost him around $1200 (they're the best you can buy Aussie built ones) which he fitted while doing the 'Camel Cut.' He used to run this truck on 32x11.50x15s but when he sold it on he took out the +2" springs and tyres, but left the +2" shocks and put on some 245/75/16 Bridgedstone Duelers on factory alloys. It has an Airflow snorkel fitted and has had diff breathers fitted. I regularly go on 4WD trips with my Dad in our Rangie, with our club and privately in the local river. This build will probably take time to get to the big $$$ stage with fabrication and all that good stuff as I'm only 14, and money doesn't grow on trees. It will be getting a +2" lift soon along with 32"s so it won't be all boring! Until I can drive it on the road (legally), I'll run it on an A-Frame so that Dad can tow me down to the river where I can muck around.

Cheers,

Trillo

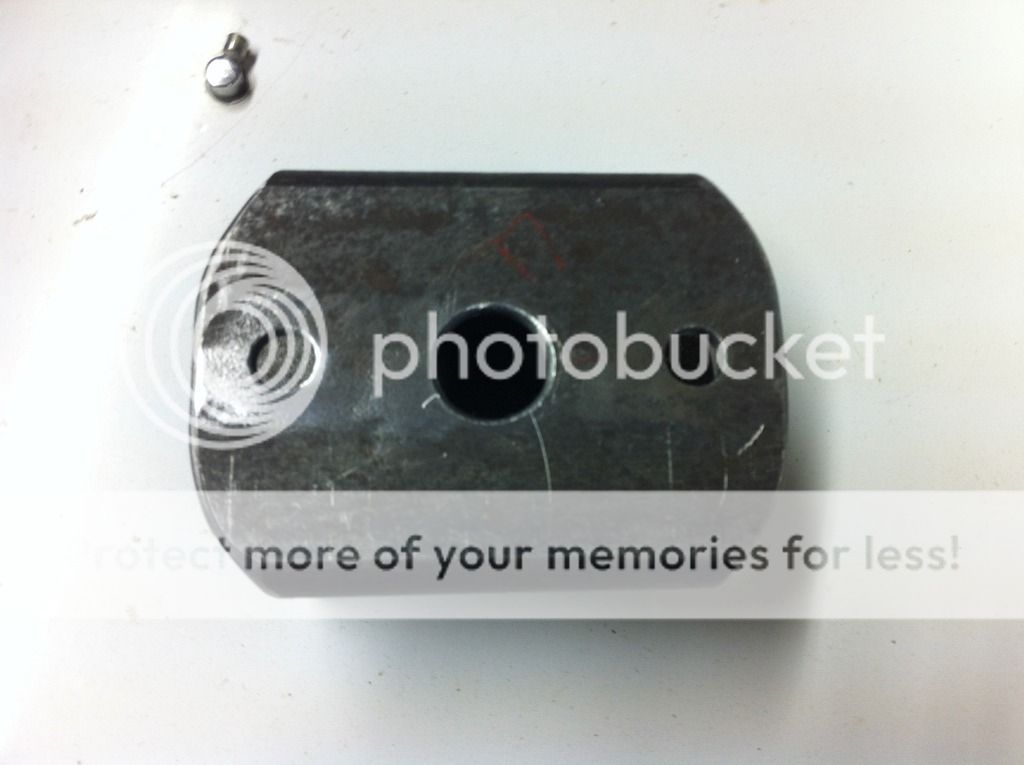

NB: The 2 inch receiver on the front isn't mine, it's Dad's

Hey guys, I'm new to this forum, but definitely not new to Landies.

I've been into off roading and Land Rovers since I was 2 years old, and now that I'm fourteen, I've got one. I bought this 1994 Honda Crossroad (essentially a Disco 1) last October. Since buying it I've put the 'Rego' on hold and parked it up, due to not having the time or funds to run it. So here it is....

Not bad for $2000 (£1000)!!!!

It has the 3.9 V8 and 183,000 kms on the clock. A previous owner (who I actually know) fitted most the mods to it so I know everythings been done right. The flares cost him around $1200 (they're the best you can buy Aussie built ones) which he fitted while doing the 'Camel Cut.' He used to run this truck on 32x11.50x15s but when he sold it on he took out the +2" springs and tyres, but left the +2" shocks and put on some 245/75/16 Bridgedstone Duelers on factory alloys. It has an Airflow snorkel fitted and has had diff breathers fitted. I regularly go on 4WD trips with my Dad in our Rangie, with our club and privately in the local river. This build will probably take time to get to the big $$$ stage with fabrication and all that good stuff as I'm only 14, and money doesn't grow on trees. It will be getting a +2" lift soon along with 32"s so it won't be all boring! Until I can drive it on the road (legally), I'll run it on an A-Frame so that Dad can tow me down to the river where I can muck around.

Cheers,

Trillo

NB: The 2 inch receiver on the front isn't mine, it's Dad's

Last edited: