southpoint

New Member

- Posts

- 7

Hi Folks,

My disco 96 300tdi has just failed MOT on sills and posts [ A & B ].

So I thought - get myself a couple of sill repair covers - A & B post base replacements from yrm - clean it up to good metal - tack it all in and get a decent welder to come along and seam weld it all in [ I am just not good enough for the seam welds ].

BUT - I am looking at what I have to do to get the sill repair plates on and I have a problem with what I can and can't do to got both the MOT passed and to get a good job done.

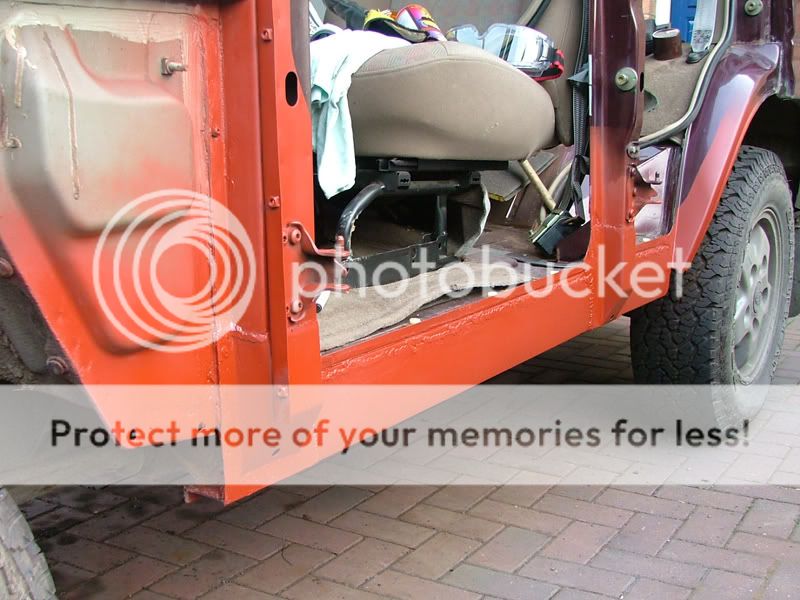

Here is a pic of the sill and a bit of floor - as it is now - not too bad plenty of clean steel at the top with only the lower sill shot.

Here is a pic of the sill repair offered up to the same side:

The BIG question here - well the 1st anyway - is that the replacement sill repair has a big flange that seems to have to go over the existing floor [ underneath the front door weather seal ] and it will fit.

Well the bolts for getting the seats out are corroded to hell so I cannot get the out without cutting the bolts so I am keen to leave the seats in place if I can - I will look at this later on.

SO - the big question - it's been bugging me big time : If I cut the flange off the replacement sill repair part [ the one that is suppose to go over the floor ] and get it seam welded on the outside of the existing sill just below the rail that holds the door seals - is that OK or is it a big structure/MOT problem???

To be honest I am a newbi at this type of stuff and any advice would be great - in fact I am in Shropshire so if anyone want to make a few quid on the seam welding or indeed advice - drop me a pm -well happy man I will be.

I am a p/t Gamekeeper and it's my daily wagon on the shoot so any help is welcomed big time

Cheers for now,

Russ

My disco 96 300tdi has just failed MOT on sills and posts [ A & B ].

So I thought - get myself a couple of sill repair covers - A & B post base replacements from yrm - clean it up to good metal - tack it all in and get a decent welder to come along and seam weld it all in [ I am just not good enough for the seam welds ].

BUT - I am looking at what I have to do to get the sill repair plates on and I have a problem with what I can and can't do to got both the MOT passed and to get a good job done.

Here is a pic of the sill and a bit of floor - as it is now - not too bad plenty of clean steel at the top with only the lower sill shot.

Here is a pic of the sill repair offered up to the same side:

The BIG question here - well the 1st anyway - is that the replacement sill repair has a big flange that seems to have to go over the existing floor [ underneath the front door weather seal ] and it will fit.

Well the bolts for getting the seats out are corroded to hell so I cannot get the out without cutting the bolts so I am keen to leave the seats in place if I can - I will look at this later on.

SO - the big question - it's been bugging me big time : If I cut the flange off the replacement sill repair part [ the one that is suppose to go over the floor ] and get it seam welded on the outside of the existing sill just below the rail that holds the door seals - is that OK or is it a big structure/MOT problem???

To be honest I am a newbi at this type of stuff and any advice would be great - in fact I am in Shropshire so if anyone want to make a few quid on the seam welding or indeed advice - drop me a pm -well happy man I will be.

I am a p/t Gamekeeper and it's my daily wagon on the shoot so any help is welcomed big time

Cheers for now,

Russ