Can anyone confirm my fears..

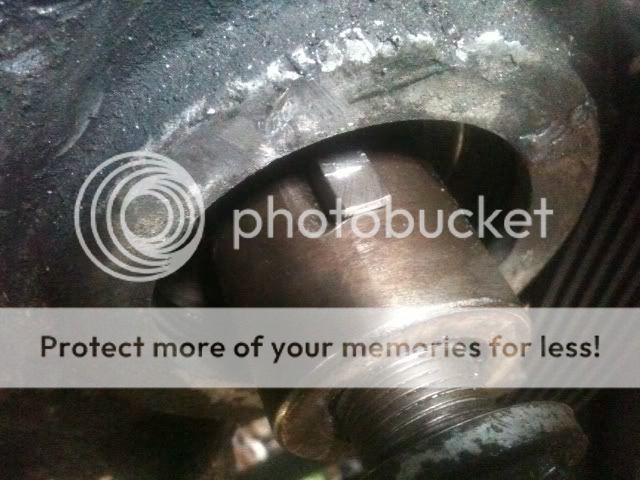

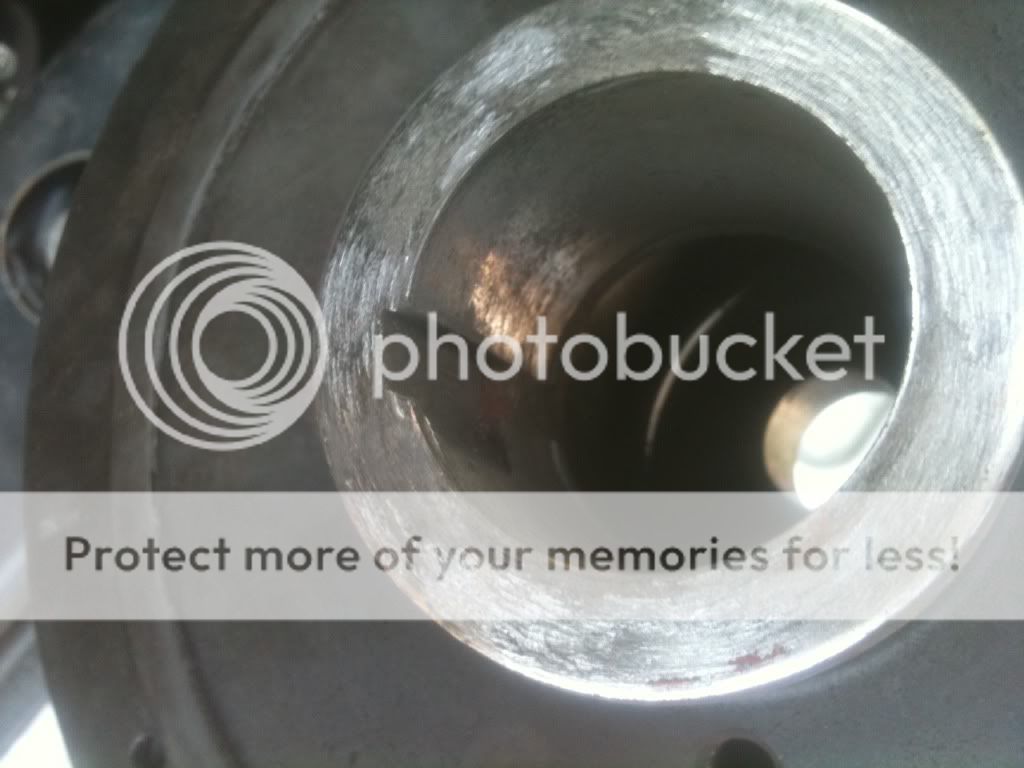

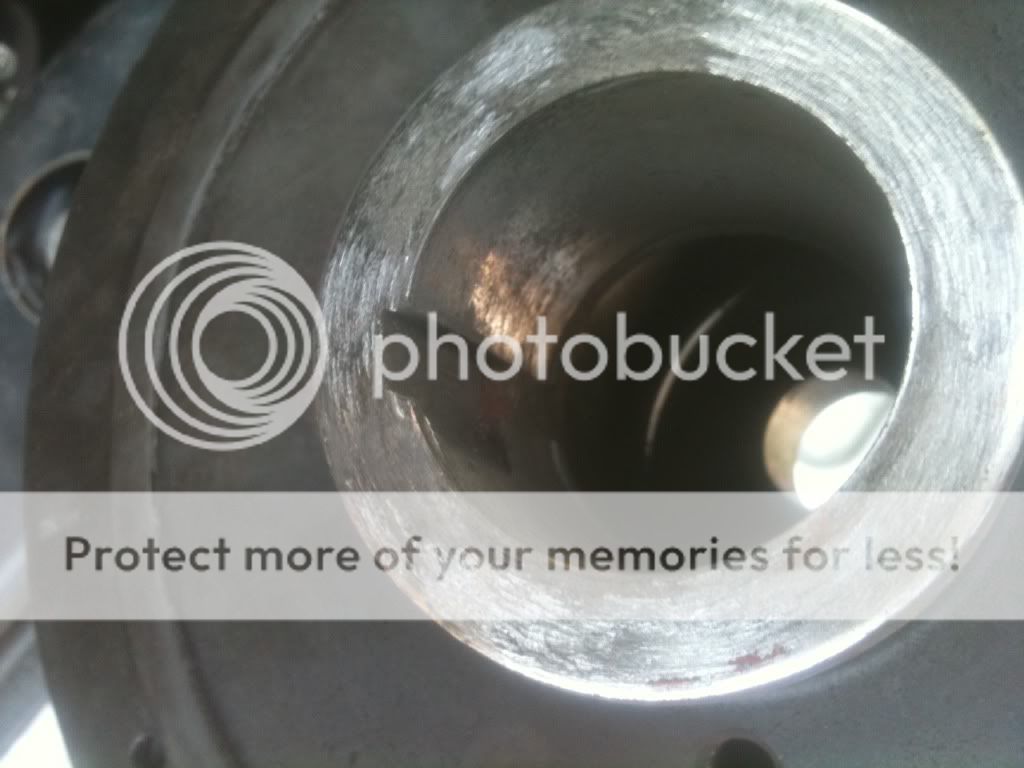

This has snapped off the crankshaft??

After splashing out for the locking tool from difflock I've managed to torque it all up okay, but theres a lot of wobble on the damper which I'm sure with time will wear out the aux belt and tensioner

This has snapped off the crankshaft??

After splashing out for the locking tool from difflock I've managed to torque it all up okay, but theres a lot of wobble on the damper which I'm sure with time will wear out the aux belt and tensioner