Hippo

Lord Hippo

- Posts

- 55,898

Updated 13 August 2017.

Please can you vote in my poll >>> What Freelander have you got poll

This write-up shows the steps I took to change the Viscous Coupling Unit (VCU) support bearings on my 2001 Freelander 1 v6. The front bearing failed. The solution was to remove the viscous coupling and both propeller (prop) shafts as a one-piece unit, then replace the bearings and refit. You can remove just the VCU and bearings on its own, but it's easier to remove the whole lot in one go. Especially if it's not been removed for a long time. The choice is yours. I've done it both ways and found removing the whole lot in one piece is easier. This guide will show you the simple steps to follow to replace your VCU's bearings.

Note: I have no financial gain from writing this guide or being a member of the forum. I don't sell parts or own a business. I own a Freelander and have done for many years which is why I'm a member of this forum.

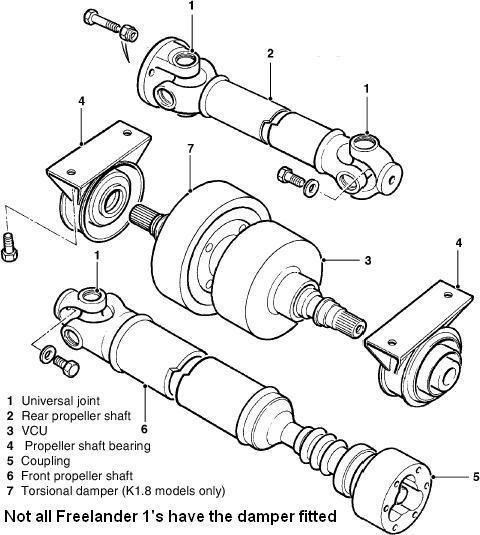

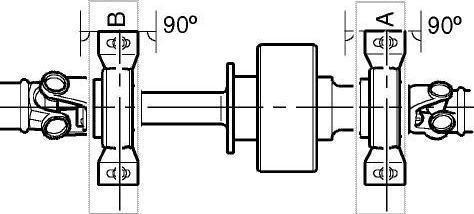

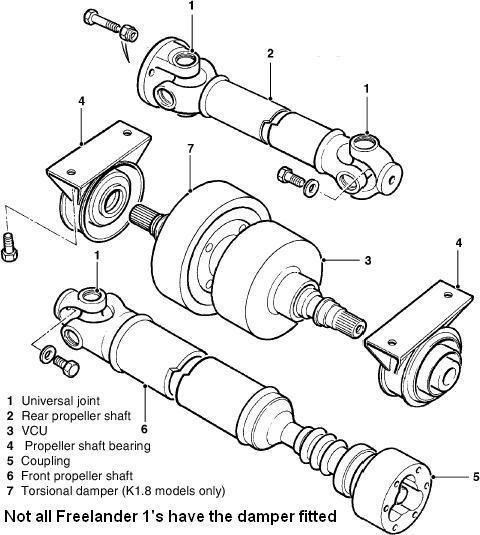

Photo of the complete VCU and prop shaft assembly below. Not all Freelander 1's have the damper (item 7) fitted. My v6 doesn't. The smoother running engine's don't have the damper fitted. The damper can fall off and spin round the VCU's shaft as you drive. You can buy the damper as a replacement on it's own. Also buy the bolts separate. It's full name is a torsional damper. It's fitted to dampen (reduce or remove) vibrations and harmonic's which travel down the prop shafts. They're created by the engine/gearbox/ird (travels through the casing) and not the vcu or the props. The rubber which sits around the vcu bearings also helps to reduce transfer into the cabin. As said not all Freelanders have the damper fitted when first built. Most replace the damper when it falls off if fitted. Some leave it off and it seems ok without. Some suddenly notice a slight drone or hum at certain higher speeds from the rear of the vehicle when the dampers removed. Resonant frequencies are difficult to locate directionally but the theory of damping them on the vcu reduces their strength so reduces the chance of them entering the cabin space.

vcusetup uZ3Qtat

There are 2x VCU's available. One for the v6 and another for all other Freelander 1's. The original VCU's fitted by LR were made by GKN and stamped GKN. Despite popular belief you can still buy brand new GKN VCU's online. They have come down significantly in price. There are also suppliers which recondition VCU's by replacing the viscous based silicon inside. Not all re-conditioners do a good job. Some purposely reduce the ability of the VCU to pass power through itself (by reducing the amount of viscous based silicon and metal disks inside the VCU) which means you may struggle to gain rear wheel drive through your VCU. They do this to reduce stress in the transmission. You end up with little or no drive to the rear wheels when you need it, if you're unfortunate to own one of these crap VCU's.

Its believed that the content (fluid and plates) inside both options of vcu are the same. The only difference being the Td4, L series diesel and 1.8 petrol versions sometimes had dampers fitted. Some of them didn't have dampers fitted.

VCU options:

TOR000010 = 1.8k series rover petrol, 2L rover diesel and Td4 BMW diesel

TOR000040 = v6 (rover kv6) petrol

There's 2 types of bearing support brackets TOQ000040 and TOW000060. They come with the bearings fitted. Try to get a good make of bearing or you'll need to change them again earlier than expected. The front bearing seems to always go first. It's worth changing them both while it's all removed. If you fit poor quality bearings they won't last long and you will have to replace them again soon. If you fit good quality bearings they will last much longer but only if you fit them on the vcu carefully/correctly.

TOQ000040

Freelander 1 - 1.8 rover k series petrol 1997 - 2006

Freelander 1 - 2L rover diesel 1997 - 2000

Freelander 1 - 2.5 v6 rover petrol 2001 - 2001

Freelander 1 - 2.5 v6 rover petrol 2002 - 2002 VIN (upto) > 2A357439

Freelander 1 - Td4 2L BMW diesel 2001 - 2006

TOQ000060 - (this type lowers the bearing by about 25mm and look slightly different to the pic below)

Freelander 1 - 2.5 v6 rover petrol 2002 - 2002 VIN 2A357440 > (onwards)

Freelander 1 - 2.5 v6 rover petrol 2003 - 2006

P2211807 ZcUw3Lw

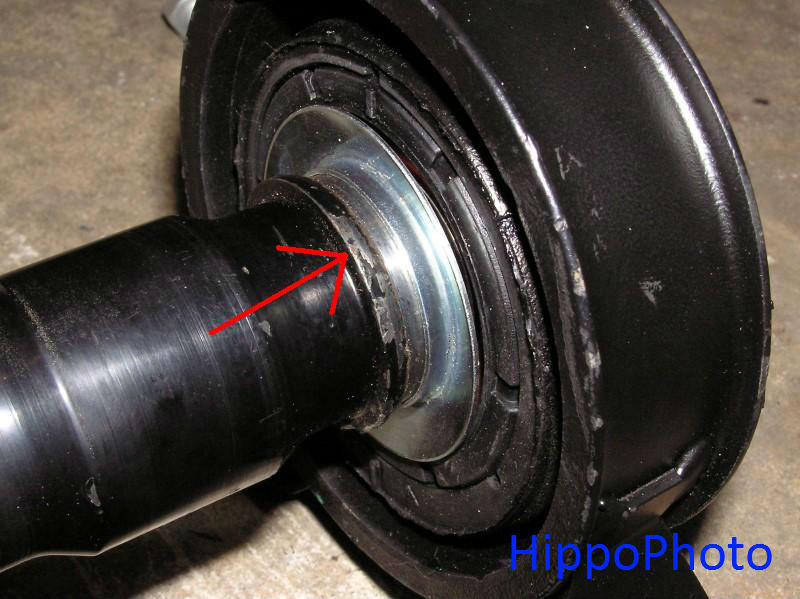

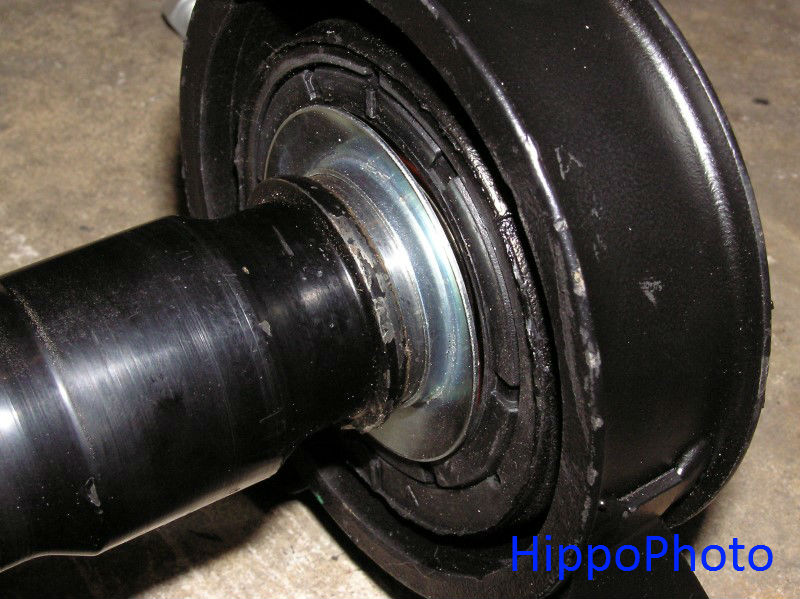

Close up of a genuine LR VCU support bearing - fitted with fag bearings - they're a good manufacturer:

P2281803a zPB3fEj

To access the underside of my Freelander I use 4 wooden HippoRamps, which I can drive up. This lifts the car 6 inches in the air for better access underneath. Also keeps it stable and level to work under.

HippoRamp build instructions over ere: http://www.landyzone.co.uk/land-rover/hipporamps-how-to-guide.257760.html

Warning: You need to chock the front wheels to stop your Freelander rolling. Don't rely on the handbrake on its own.

hipporamps EGR3kqR

Remove the rear prop shaft to rear diff connection. E12 torx bolts and 17mm nuts x4. If you can't reach the nut at the top, rolling the car forwards or backwards 10 inches will rotate the prop shaft 90 degrees. I appreciate this is difficult when your Freelander is on ramps. My HippoRamps are 24 inches long so it's possible.

P2271801 QllJ1VB

Separate the prop shaft from the rear diff and support. I used an axle stand to support my rear prop shaft. The rear prop shaft weighs 7kg. If it's allowed to drop you risk damaging the universal joint at the other end.

rearprop QG4NFDX

This is a good time to check your rear diff centre mount. This is located in the photo below, to the left of the diff flange. These mounts are known to fail on Freelanders. You hear a bang from the rear end when pulling away or changing gear. The video below shows the movement of a failed mount. If yours is ok, it won't move as much as my failed unit in the video.

Land Rover Freelander 1 2001 v6 Centre Diff Mount Fail - YouTube

Use this link to find out how to re[place the rear diff mounts:

http://www.landyzone.co.uk/land-rover/rear-diff-mount-replacement-how-to-guide.101774.html

reardiff i6x8NPF

There's also a further 2 rear diff mounts. These don't fail as often as the centre mount. Now is a good time to check them. View of both the LHS and RHS rear diff mounts from underneath:

P3061820 xdmolvD

Back to the VCU replacement:

Remove the front prop shaft to IRD connection. E10 or E11 torx bolts and 13mm nuts x6. It's a bit fiddly to reach all the nuts. With the use of an extension bar and elbow it's easily done. If you can't reach the nut at the top, roll the car forwards or backwards 10 inches which rotates the prop shaft 90 degrees.

Separate the prop shaft from the IRD by pulling back the metal collar. This can be done with the bolts and 3 plates left in place. My collar doesn't have the gaiter as it ripped off.

P2271842 dUOsyci

Since these photos were taken I've fitted a new gaiter and included a pic so you can see it. This type has a thicker rubber collar when compared to the original LR fitted concertina gaiters. It's stronger and won't rip off so easily like the originals do. This thread will help you change your gaiter:

http://www.landyzone.co.uk/land-rover/prop-sorted.162093-2.html

DSCN2189 z3TQrUk

The front prop shaft weights 9kg. I supported mine on an axle stands. If you allow it to drop you risk damaging the universal joint at the other end.

P2271843 ZD5T0X5

Now start to undo the bolts holding the VCU support bearings. 10mm x4. I placed axle stands under my VCU to support the weight. The VCU and bearings weigh 9kg. Try to get the supports as high as possible so you don't have to take the weight of the VCU after undoing the bolts. I used blocks of wood under the axle stands to help lift them up.

P2271848 dpyYhdk

Fully remove the support bearing bolts and support the VCU on axle stands.

P2271853 Bl7McWL

You should now have the whole prop shaft and VCU assembly disconnected and supported under your Freelander. Gradually lower the whole assembly as one unit to the ground. In total it weighs 25kg. Try not to bend the prop shaft universal joints more than 10 degrees or allow them to drop or you risk damaging the universal joints. Your Freelander is now in "Mondo Mode" (what we call it) front wheel drive only. This is because you have disconnected and removed the VCU and prop shafts, which means you have removed engine drive to the rear wheels.

P2271855 ize6TNJ

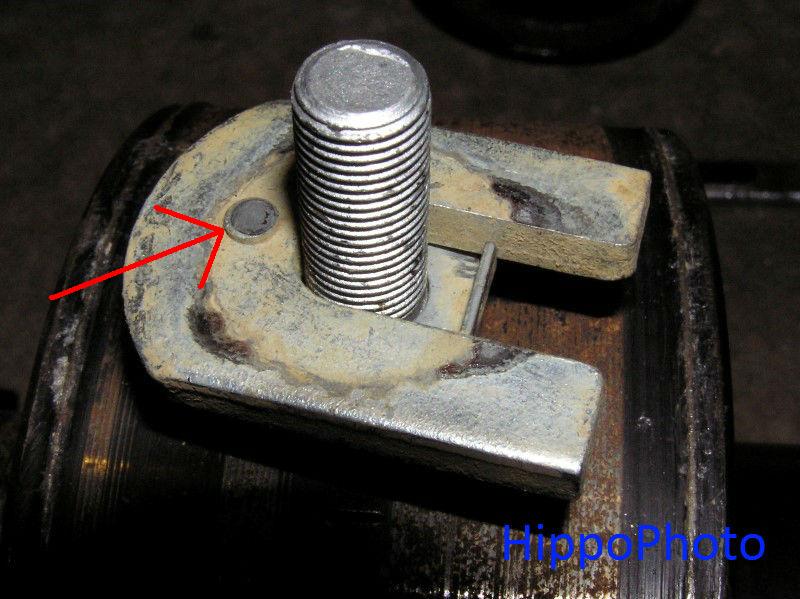

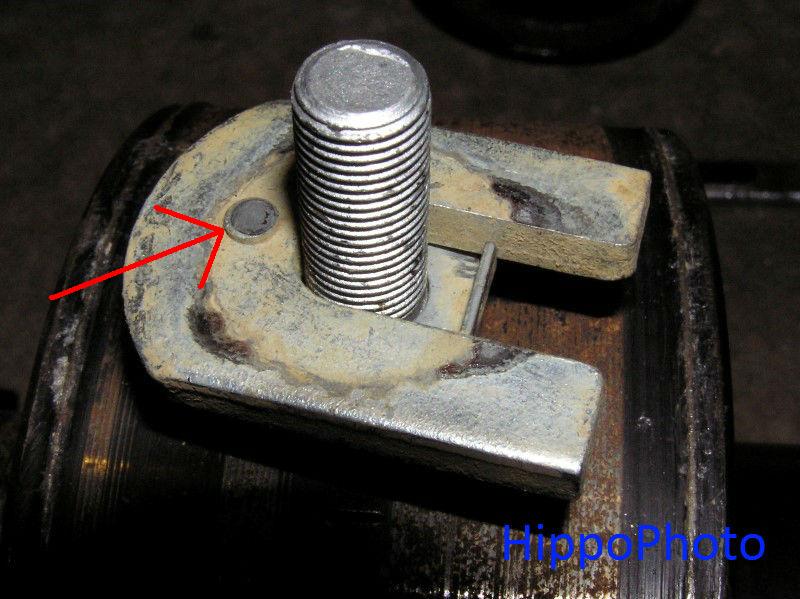

Place the whole assembly on a flat surface. Support the weight of the VCU using wood under the support bearings. Separate the prop shafts by undoing the 17mm x2 bolts. You'll need a 17mm ring spanner to do this due to lack of space. These bolts will have 65Nm of torque on them. Use a 17mm spanner and a long screw driver as a lever (red line in photo below). Put the screw driver through the universal joint next to the bolt your undoing. Be careful not to damage the universal joint when doing this.

P2271857b QOWorhr

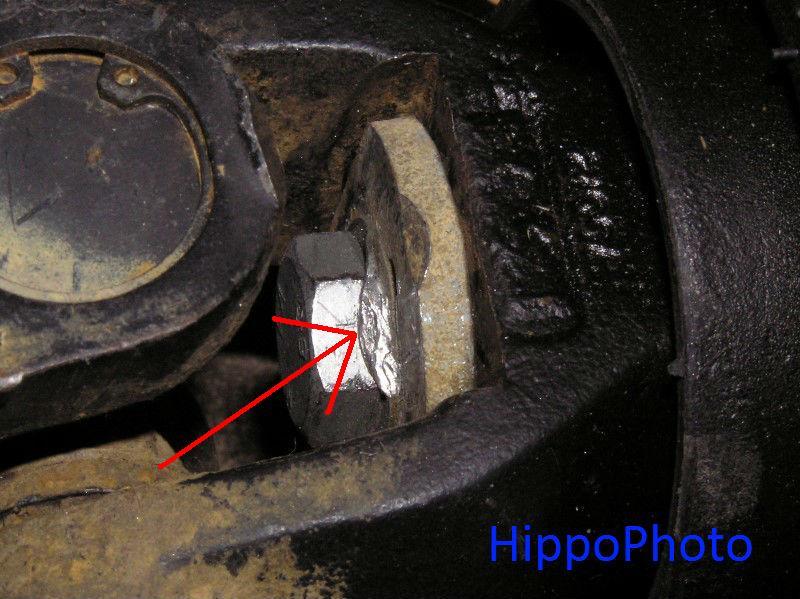

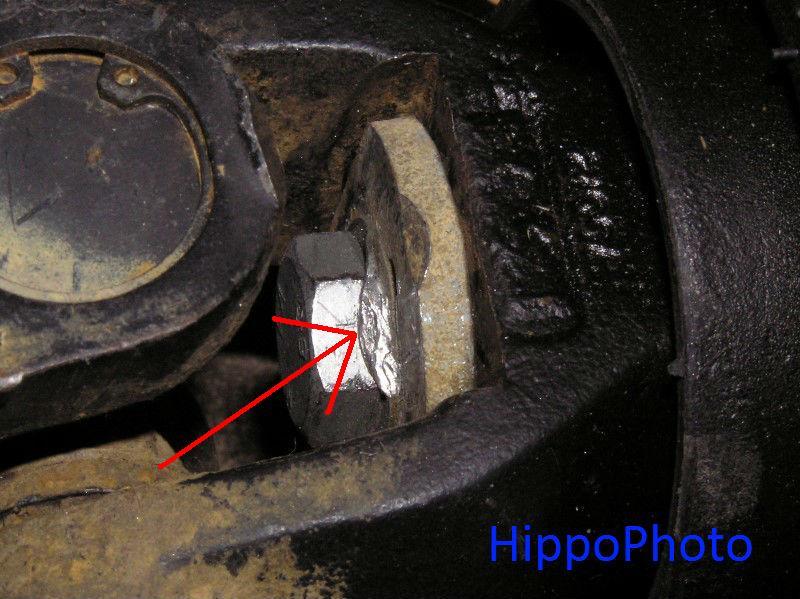

Repeat the same procedure to remove the bolt at the other end of the VCU. Again, put the screw driver (red line in photo below) through the universal joint next to the bolt your undoing. Be careful not to damage the universal joint when doing this.

P2271857a aCmjdQA

Unscrew the bolts at both ends just enough to remove the U shaped spacer. The bolt in the photo below has been unscrewed too far. If you do this you won't be able to use the bolt to force the prop off the VCU's spline.

P2271858 4ae6kjl

Support the prop shaft and universal joint with a block of wood. Use a tapered rod or cold chisel to separate the prop shaft from the VCU spines. Unscrew the bolt to allow perfect positioning of a chisel to just pass into the assembly. Carefully hammer the chisel through and the prop shaft will start to release from the VCU spines. You will probably need to repeat the exercise several times, each time unscrewing the bolt a few more turns, until the joint separates.

P2281806 FieqR7c

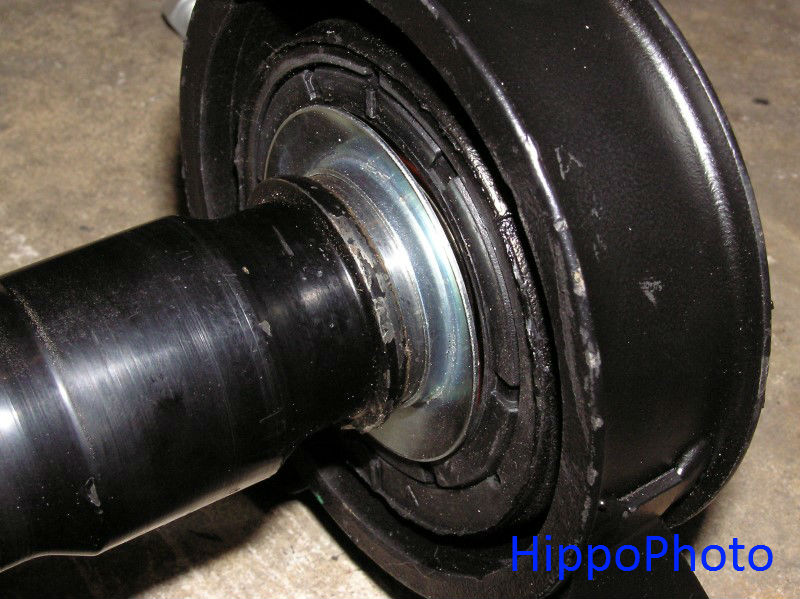

Picture below shows the VCU support bearing and spines, with the prop shaft removed. The bolt has been refitted afterwards. Repeat the exercise to remove the prop shaft at the other end of the VCU. Keep both small washers.

P2281805 JBjli6f

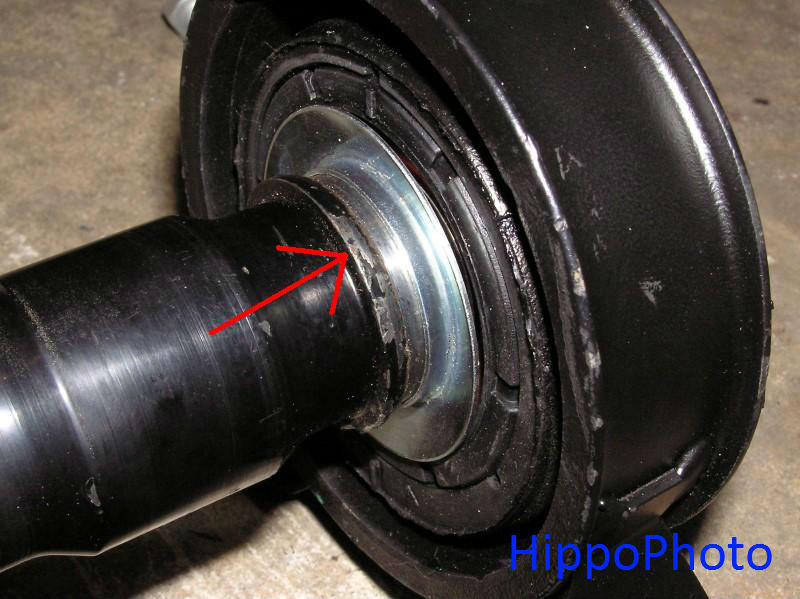

Now pull the bearing off the VCU. They push fit. Unfortunately mine wouldn't tap off with a hammer, so I had to cut through the rubber to remove the support bracket.

P2281820 9PqE7Z5

Then I used a puller to pull the bearing off the VCU. Not the best solution, but one which worked ok for me. Other options are available.

P2281816 X6NN292

Below photo of bearing and washer removed from the spline.

P2281818 1DnT3Dd

To reassemble: Fit 1 inner washer on both ends of the VCU. They're push fit, but it's easier with a little tap with a hammer on opposing sides until it's nearly pushed home. Make sure you fit them the correct way round. Photo below shows the washer pushed home too much by about 4mm. I'll explain why later on. As my splines have started to rust, I've also used some sand paper to remove some of the rust to make refitting easier later on.

P2281800 UUCkDGs

I also used sand paper in the ends of the propeller shaft spilnes to remove some of the surface rust.

P2281802 GTYu5Xq

When fitting the new support bearings you need to use the flange arrowed in the photo below, to support the VCU whilst pushing the bearing into position. There's a flange at both ends of the VCU. If you don't support the flange then you risk damaging your VCU. Using the flange means you're not transferring the pressure through the VCU, which is what would happen if you allowed the force to pass through the VCU and out of the other end, against something like the floor.

P3041803a MKADNyL

Now fit the support bearing on the end of the VCU. You should really use a press to fit these. Garages or metal workshops will have them. They will happily fit/remove bearings for you for a small fee. As I haven't got a press, I pushed mine on with a deep socket and gentle hammer taps. If your careful and put the bearing on straight it's easy to do. The socket was matched to the size of the inner bearing race track, to ensure the pressure only went on the inner bearing race track. Do the same to the new support bearing at the other end. I used a very small amount of grease on the splines to help mine push home easier. Fitting the bearings like this is a bit of a risk. If it's not done properly it could damage the bearings. Some would say this method is a bodge, but it worked ok for me.

P2281804 BlsfThK

Socket used to push the inner bearing race track home. Be careful not to damage the bearing or VCU if you use this method. Socket should only push against the inner bearing race track. I used a 30mm socket. The correct size of socket is one big enough to fit over the splines (internal socket diameter), and small enough to push on the inner bearing race track only (max outer diameter of socket) and long enough to push the bearing onto the shaft.

P22818051 lh5SO6T

Fit the new washer to both prop shafts. This is push fit, but it's easier with a little tap with a hammer on opposing sides until it's nearly pushed home. Make sure you fit them the correct way round. They only need to be pushed on to sit flush with the end of the prop shaft. I greased the inner splines of the prop shafts to make them easier to reassemble.

P3041801 xjc7Psw

To reassemble: Place both prop shafts and VCU in a straight line on a flat surface. Slide the prop shafts onto the VCU spines by hand. Don't push them too far without reading the next instruction below, as this will make it easier to fit the bolts and U shaped spacer.

Fit the thin washer and U shaped spacer to the bolts as shown below. Note the position of the small tab on the U shaped washer arrowed. When fitted, this will be on the side closest to the VCU. The tab stops the U shaped spacer from falling off when fitted.

P3041804 MLUGknq

Screw the bolts into the end of the VCU as shown below.

P3041805 zb9Bora

Use a 17mm ring spanner to tighten the bolts. This process will pull the prop shaft fully home onto the VCU spines if it isn't already fully home. Torque should be 65Nm. You will need to use a long screw driver (red line in photos below) pushed through the universal joint next to the bolt your tightening, to use as a lever. Don't use a lever at the other end of the VCU or this will pass the bolt tightening force through the VCU. Hence you can't be sure the bolt has been tightened correctly. Correct bolt torque is 65Nm. Be careful not to damage the universal joint with the screw driver. Repeat this process for the bolt holding the other prop shaft, moving the screw driver to the other end's universal joint as a lever.

You won't be able to tighten up these bolts with a torque wrench due to poor access. I did mine as per this guide, with ring spanners. To get the correct torque on the nuts I practiced on a nut and bolt to see what 65Nm felt like with a torque wrench, then took care to apply the same amount of torque to the bolts. If you hold the torque wrench the same distance from the nut as you would a spanner, then this is a good guide. Not the ideal method, but the best one I have.

P3041806 9yHpX4x

P2271857b QOWorhr

P2271857a aCmjdQA

Once both bolts have been set to the correct torque, bend the thin washer over the flat side of the bolt head to help stop it from turning.

P3151814 0FcyAgx

Using a screwdriver, carefully push the inner washer towards the VCU bearing to reduce the gap to stop ingress of dirt. Repeat this at the other end of the VCU, on the inner washer. It doesn't give the bearing 100% protection but it does give some protection.

P3041803 Rdv4zss

Refitting is the reverse of removal. Care should be taken to make sure the whole assembly is supported correctly on axle stands, underneath the Freelander, without bending the prop shafts more than 10 degrees. If they're bent too far you risk damaging the universal joints. The complete assembly weighs 25kg in total.

P2271855 ize6TNJ

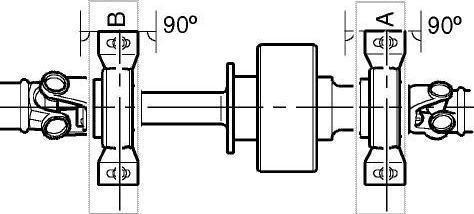

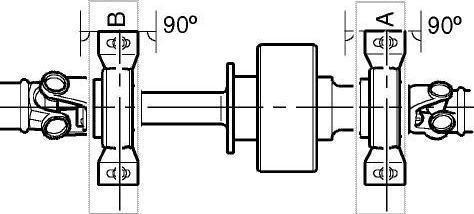

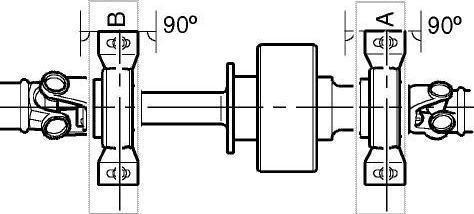

Raise the VCU towards the under body of the Freelander and fit the bearing support bracket bolts. Size 10mm. Screw in the bolts until just hand tight. Position the VCU support bracket bearings to align parallel with the struts under your Freelander. Visually aligning the brackets 90 degrees to the shaft going through the VCU is good enough. The pic below is from LR's rave disk. They want you to do as best you can to align the brackets. You will need to recheck the position before securing at the end so just align roughly for now.

vcu90degrees D1NBTTZ

P2271848 dpyYhdk

Connect the front prop shaft to the IRD and slide the collar home forwards towards the IRD. Slide the 6 bolts through and secure. E10 or E11 torx bolts and 13mm nuts x6. Torque is 40Nm. It's a bit fiddly to reach all the nuts. With the use of an extension bar and elbow it's easily done. If you can't reach the nut at the top, roll the car forwards or backwards 10 inches which rotates the prop shaft 90 degrees.

P2271826 FgMouP6

Connect the rear propeller shaft to the rear diff. Use a small amount of grease on the mating faces. E12 torx bolts and 17mm nuts x4. Torque is 65Nm. If the holes are out of alignment put 2 large screw drivers through the universal joints either side of the VCU and turn the rear propeller shaft to aline the holes.

P2271801 QllJ1VB

Finally check the alignment of the VCU. You'll feel the VCU settle in to position. The support bearings should be 90 degrees to the shaft running through the VCU, and parallel to the under body struts, as shown below. Visual alignment is enough. Once correctly aligned, torque the 4x 10mm bolts to 28Nm.

vcu90degrees D1NBTTZ

It's important to note the VCU and support bearings are aligned parallel to the under body struts, even though both prop shafts run at slight diagonals. This is how the prop and VCU fits normally. The universal joints bend as they turn which allows it all to work ok like this. This is how LR designed it to be.

under1 XvnrIXn

Lower your Freelander to the ground and test-drive.

Please can you vote in my poll >>> What Freelander have you got poll

This write-up shows the steps I took to change the Viscous Coupling Unit (VCU) support bearings on my 2001 Freelander 1 v6. The front bearing failed. The solution was to remove the viscous coupling and both propeller (prop) shafts as a one-piece unit, then replace the bearings and refit. You can remove just the VCU and bearings on its own, but it's easier to remove the whole lot in one go. Especially if it's not been removed for a long time. The choice is yours. I've done it both ways and found removing the whole lot in one piece is easier. This guide will show you the simple steps to follow to replace your VCU's bearings.

Note: I have no financial gain from writing this guide or being a member of the forum. I don't sell parts or own a business. I own a Freelander and have done for many years which is why I'm a member of this forum.

Photo of the complete VCU and prop shaft assembly below. Not all Freelander 1's have the damper (item 7) fitted. My v6 doesn't. The smoother running engine's don't have the damper fitted. The damper can fall off and spin round the VCU's shaft as you drive. You can buy the damper as a replacement on it's own. Also buy the bolts separate. It's full name is a torsional damper. It's fitted to dampen (reduce or remove) vibrations and harmonic's which travel down the prop shafts. They're created by the engine/gearbox/ird (travels through the casing) and not the vcu or the props. The rubber which sits around the vcu bearings also helps to reduce transfer into the cabin. As said not all Freelanders have the damper fitted when first built. Most replace the damper when it falls off if fitted. Some leave it off and it seems ok without. Some suddenly notice a slight drone or hum at certain higher speeds from the rear of the vehicle when the dampers removed. Resonant frequencies are difficult to locate directionally but the theory of damping them on the vcu reduces their strength so reduces the chance of them entering the cabin space.

vcusetup uZ3Qtat

There are 2x VCU's available. One for the v6 and another for all other Freelander 1's. The original VCU's fitted by LR were made by GKN and stamped GKN. Despite popular belief you can still buy brand new GKN VCU's online. They have come down significantly in price. There are also suppliers which recondition VCU's by replacing the viscous based silicon inside. Not all re-conditioners do a good job. Some purposely reduce the ability of the VCU to pass power through itself (by reducing the amount of viscous based silicon and metal disks inside the VCU) which means you may struggle to gain rear wheel drive through your VCU. They do this to reduce stress in the transmission. You end up with little or no drive to the rear wheels when you need it, if you're unfortunate to own one of these crap VCU's.

Its believed that the content (fluid and plates) inside both options of vcu are the same. The only difference being the Td4, L series diesel and 1.8 petrol versions sometimes had dampers fitted. Some of them didn't have dampers fitted.

VCU options:

TOR000010 = 1.8k series rover petrol, 2L rover diesel and Td4 BMW diesel

TOR000040 = v6 (rover kv6) petrol

There's 2 types of bearing support brackets TOQ000040 and TOW000060. They come with the bearings fitted. Try to get a good make of bearing or you'll need to change them again earlier than expected. The front bearing seems to always go first. It's worth changing them both while it's all removed. If you fit poor quality bearings they won't last long and you will have to replace them again soon. If you fit good quality bearings they will last much longer but only if you fit them on the vcu carefully/correctly.

TOQ000040

Freelander 1 - 1.8 rover k series petrol 1997 - 2006

Freelander 1 - 2L rover diesel 1997 - 2000

Freelander 1 - 2.5 v6 rover petrol 2001 - 2001

Freelander 1 - 2.5 v6 rover petrol 2002 - 2002 VIN (upto) > 2A357439

Freelander 1 - Td4 2L BMW diesel 2001 - 2006

TOQ000060 - (this type lowers the bearing by about 25mm and look slightly different to the pic below)

Freelander 1 - 2.5 v6 rover petrol 2002 - 2002 VIN 2A357440 > (onwards)

Freelander 1 - 2.5 v6 rover petrol 2003 - 2006

P2211807 ZcUw3Lw

Close up of a genuine LR VCU support bearing - fitted with fag bearings - they're a good manufacturer:

P2281803a zPB3fEj

To access the underside of my Freelander I use 4 wooden HippoRamps, which I can drive up. This lifts the car 6 inches in the air for better access underneath. Also keeps it stable and level to work under.

HippoRamp build instructions over ere: http://www.landyzone.co.uk/land-rover/hipporamps-how-to-guide.257760.html

Warning: You need to chock the front wheels to stop your Freelander rolling. Don't rely on the handbrake on its own.

hipporamps EGR3kqR

Remove the rear prop shaft to rear diff connection. E12 torx bolts and 17mm nuts x4. If you can't reach the nut at the top, rolling the car forwards or backwards 10 inches will rotate the prop shaft 90 degrees. I appreciate this is difficult when your Freelander is on ramps. My HippoRamps are 24 inches long so it's possible.

P2271801 QllJ1VB

Separate the prop shaft from the rear diff and support. I used an axle stand to support my rear prop shaft. The rear prop shaft weighs 7kg. If it's allowed to drop you risk damaging the universal joint at the other end.

rearprop QG4NFDX

This is a good time to check your rear diff centre mount. This is located in the photo below, to the left of the diff flange. These mounts are known to fail on Freelanders. You hear a bang from the rear end when pulling away or changing gear. The video below shows the movement of a failed mount. If yours is ok, it won't move as much as my failed unit in the video.

Land Rover Freelander 1 2001 v6 Centre Diff Mount Fail - YouTube

Use this link to find out how to re[place the rear diff mounts:

http://www.landyzone.co.uk/land-rover/rear-diff-mount-replacement-how-to-guide.101774.html

reardiff i6x8NPF

There's also a further 2 rear diff mounts. These don't fail as often as the centre mount. Now is a good time to check them. View of both the LHS and RHS rear diff mounts from underneath:

P3061820 xdmolvD

Back to the VCU replacement:

Remove the front prop shaft to IRD connection. E10 or E11 torx bolts and 13mm nuts x6. It's a bit fiddly to reach all the nuts. With the use of an extension bar and elbow it's easily done. If you can't reach the nut at the top, roll the car forwards or backwards 10 inches which rotates the prop shaft 90 degrees.

Separate the prop shaft from the IRD by pulling back the metal collar. This can be done with the bolts and 3 plates left in place. My collar doesn't have the gaiter as it ripped off.

P2271842 dUOsyci

Since these photos were taken I've fitted a new gaiter and included a pic so you can see it. This type has a thicker rubber collar when compared to the original LR fitted concertina gaiters. It's stronger and won't rip off so easily like the originals do. This thread will help you change your gaiter:

http://www.landyzone.co.uk/land-rover/prop-sorted.162093-2.html

DSCN2189 z3TQrUk

The front prop shaft weights 9kg. I supported mine on an axle stands. If you allow it to drop you risk damaging the universal joint at the other end.

P2271843 ZD5T0X5

Now start to undo the bolts holding the VCU support bearings. 10mm x4. I placed axle stands under my VCU to support the weight. The VCU and bearings weigh 9kg. Try to get the supports as high as possible so you don't have to take the weight of the VCU after undoing the bolts. I used blocks of wood under the axle stands to help lift them up.

P2271848 dpyYhdk

Fully remove the support bearing bolts and support the VCU on axle stands.

P2271853 Bl7McWL

You should now have the whole prop shaft and VCU assembly disconnected and supported under your Freelander. Gradually lower the whole assembly as one unit to the ground. In total it weighs 25kg. Try not to bend the prop shaft universal joints more than 10 degrees or allow them to drop or you risk damaging the universal joints. Your Freelander is now in "Mondo Mode" (what we call it) front wheel drive only. This is because you have disconnected and removed the VCU and prop shafts, which means you have removed engine drive to the rear wheels.

P2271855 ize6TNJ

Place the whole assembly on a flat surface. Support the weight of the VCU using wood under the support bearings. Separate the prop shafts by undoing the 17mm x2 bolts. You'll need a 17mm ring spanner to do this due to lack of space. These bolts will have 65Nm of torque on them. Use a 17mm spanner and a long screw driver as a lever (red line in photo below). Put the screw driver through the universal joint next to the bolt your undoing. Be careful not to damage the universal joint when doing this.

P2271857b QOWorhr

Repeat the same procedure to remove the bolt at the other end of the VCU. Again, put the screw driver (red line in photo below) through the universal joint next to the bolt your undoing. Be careful not to damage the universal joint when doing this.

P2271857a aCmjdQA

Unscrew the bolts at both ends just enough to remove the U shaped spacer. The bolt in the photo below has been unscrewed too far. If you do this you won't be able to use the bolt to force the prop off the VCU's spline.

P2271858 4ae6kjl

Support the prop shaft and universal joint with a block of wood. Use a tapered rod or cold chisel to separate the prop shaft from the VCU spines. Unscrew the bolt to allow perfect positioning of a chisel to just pass into the assembly. Carefully hammer the chisel through and the prop shaft will start to release from the VCU spines. You will probably need to repeat the exercise several times, each time unscrewing the bolt a few more turns, until the joint separates.

P2281806 FieqR7c

Picture below shows the VCU support bearing and spines, with the prop shaft removed. The bolt has been refitted afterwards. Repeat the exercise to remove the prop shaft at the other end of the VCU. Keep both small washers.

P2281805 JBjli6f

Now pull the bearing off the VCU. They push fit. Unfortunately mine wouldn't tap off with a hammer, so I had to cut through the rubber to remove the support bracket.

P2281820 9PqE7Z5

Then I used a puller to pull the bearing off the VCU. Not the best solution, but one which worked ok for me. Other options are available.

P2281816 X6NN292

Below photo of bearing and washer removed from the spline.

P2281818 1DnT3Dd

To reassemble: Fit 1 inner washer on both ends of the VCU. They're push fit, but it's easier with a little tap with a hammer on opposing sides until it's nearly pushed home. Make sure you fit them the correct way round. Photo below shows the washer pushed home too much by about 4mm. I'll explain why later on. As my splines have started to rust, I've also used some sand paper to remove some of the rust to make refitting easier later on.

P2281800 UUCkDGs

I also used sand paper in the ends of the propeller shaft spilnes to remove some of the surface rust.

P2281802 GTYu5Xq

When fitting the new support bearings you need to use the flange arrowed in the photo below, to support the VCU whilst pushing the bearing into position. There's a flange at both ends of the VCU. If you don't support the flange then you risk damaging your VCU. Using the flange means you're not transferring the pressure through the VCU, which is what would happen if you allowed the force to pass through the VCU and out of the other end, against something like the floor.

P3041803a MKADNyL

Now fit the support bearing on the end of the VCU. You should really use a press to fit these. Garages or metal workshops will have them. They will happily fit/remove bearings for you for a small fee. As I haven't got a press, I pushed mine on with a deep socket and gentle hammer taps. If your careful and put the bearing on straight it's easy to do. The socket was matched to the size of the inner bearing race track, to ensure the pressure only went on the inner bearing race track. Do the same to the new support bearing at the other end. I used a very small amount of grease on the splines to help mine push home easier. Fitting the bearings like this is a bit of a risk. If it's not done properly it could damage the bearings. Some would say this method is a bodge, but it worked ok for me.

P2281804 BlsfThK

Socket used to push the inner bearing race track home. Be careful not to damage the bearing or VCU if you use this method. Socket should only push against the inner bearing race track. I used a 30mm socket. The correct size of socket is one big enough to fit over the splines (internal socket diameter), and small enough to push on the inner bearing race track only (max outer diameter of socket) and long enough to push the bearing onto the shaft.

P22818051 lh5SO6T

Fit the new washer to both prop shafts. This is push fit, but it's easier with a little tap with a hammer on opposing sides until it's nearly pushed home. Make sure you fit them the correct way round. They only need to be pushed on to sit flush with the end of the prop shaft. I greased the inner splines of the prop shafts to make them easier to reassemble.

P3041801 xjc7Psw

To reassemble: Place both prop shafts and VCU in a straight line on a flat surface. Slide the prop shafts onto the VCU spines by hand. Don't push them too far without reading the next instruction below, as this will make it easier to fit the bolts and U shaped spacer.

Fit the thin washer and U shaped spacer to the bolts as shown below. Note the position of the small tab on the U shaped washer arrowed. When fitted, this will be on the side closest to the VCU. The tab stops the U shaped spacer from falling off when fitted.

P3041804 MLUGknq

Screw the bolts into the end of the VCU as shown below.

P3041805 zb9Bora

Use a 17mm ring spanner to tighten the bolts. This process will pull the prop shaft fully home onto the VCU spines if it isn't already fully home. Torque should be 65Nm. You will need to use a long screw driver (red line in photos below) pushed through the universal joint next to the bolt your tightening, to use as a lever. Don't use a lever at the other end of the VCU or this will pass the bolt tightening force through the VCU. Hence you can't be sure the bolt has been tightened correctly. Correct bolt torque is 65Nm. Be careful not to damage the universal joint with the screw driver. Repeat this process for the bolt holding the other prop shaft, moving the screw driver to the other end's universal joint as a lever.

You won't be able to tighten up these bolts with a torque wrench due to poor access. I did mine as per this guide, with ring spanners. To get the correct torque on the nuts I practiced on a nut and bolt to see what 65Nm felt like with a torque wrench, then took care to apply the same amount of torque to the bolts. If you hold the torque wrench the same distance from the nut as you would a spanner, then this is a good guide. Not the ideal method, but the best one I have.

P3041806 9yHpX4x

P2271857b QOWorhr

P2271857a aCmjdQA

Once both bolts have been set to the correct torque, bend the thin washer over the flat side of the bolt head to help stop it from turning.

P3151814 0FcyAgx

Using a screwdriver, carefully push the inner washer towards the VCU bearing to reduce the gap to stop ingress of dirt. Repeat this at the other end of the VCU, on the inner washer. It doesn't give the bearing 100% protection but it does give some protection.

P3041803 Rdv4zss

Refitting is the reverse of removal. Care should be taken to make sure the whole assembly is supported correctly on axle stands, underneath the Freelander, without bending the prop shafts more than 10 degrees. If they're bent too far you risk damaging the universal joints. The complete assembly weighs 25kg in total.

P2271855 ize6TNJ

Raise the VCU towards the under body of the Freelander and fit the bearing support bracket bolts. Size 10mm. Screw in the bolts until just hand tight. Position the VCU support bracket bearings to align parallel with the struts under your Freelander. Visually aligning the brackets 90 degrees to the shaft going through the VCU is good enough. The pic below is from LR's rave disk. They want you to do as best you can to align the brackets. You will need to recheck the position before securing at the end so just align roughly for now.

vcu90degrees D1NBTTZ

P2271848 dpyYhdk

Connect the front prop shaft to the IRD and slide the collar home forwards towards the IRD. Slide the 6 bolts through and secure. E10 or E11 torx bolts and 13mm nuts x6. Torque is 40Nm. It's a bit fiddly to reach all the nuts. With the use of an extension bar and elbow it's easily done. If you can't reach the nut at the top, roll the car forwards or backwards 10 inches which rotates the prop shaft 90 degrees.

P2271826 FgMouP6

Connect the rear propeller shaft to the rear diff. Use a small amount of grease on the mating faces. E12 torx bolts and 17mm nuts x4. Torque is 65Nm. If the holes are out of alignment put 2 large screw drivers through the universal joints either side of the VCU and turn the rear propeller shaft to aline the holes.

P2271801 QllJ1VB

Finally check the alignment of the VCU. You'll feel the VCU settle in to position. The support bearings should be 90 degrees to the shaft running through the VCU, and parallel to the under body struts, as shown below. Visual alignment is enough. Once correctly aligned, torque the 4x 10mm bolts to 28Nm.

vcu90degrees D1NBTTZ

It's important to note the VCU and support bearings are aligned parallel to the under body struts, even though both prop shafts run at slight diagonals. This is how the prop and VCU fits normally. The universal joints bend as they turn which allows it all to work ok like this. This is how LR designed it to be.

under1 XvnrIXn

Lower your Freelander to the ground and test-drive.

Last edited: