BigUnZ

New Member

- Posts

- 24

- Location

- Keflavik, Iceland

if the icelandic goverment keep their "superb" job ongoing, can I then move into your garage with my landy? It's a bit rusty so I'm pretty sure I can fold it up in a suitcase.

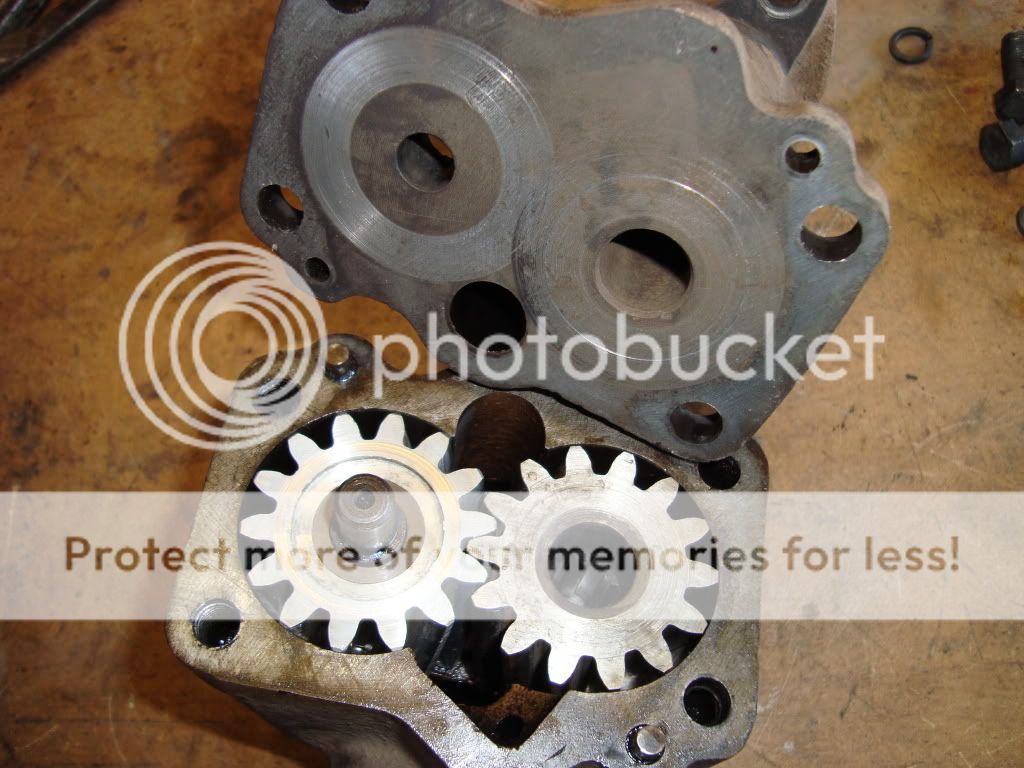

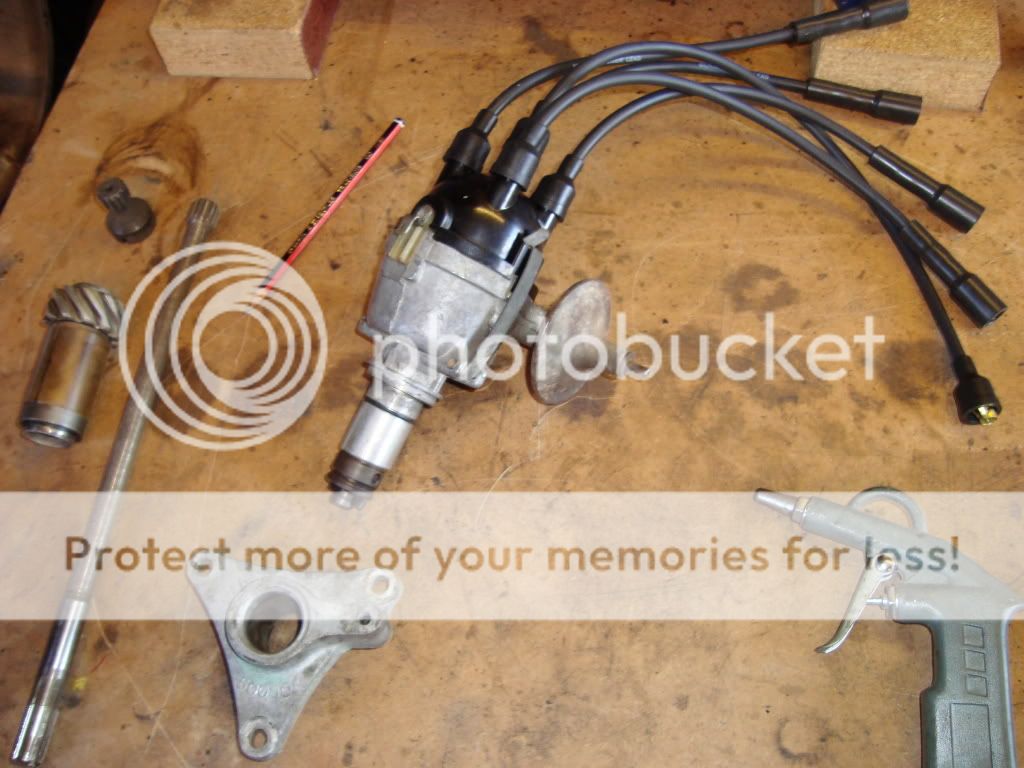

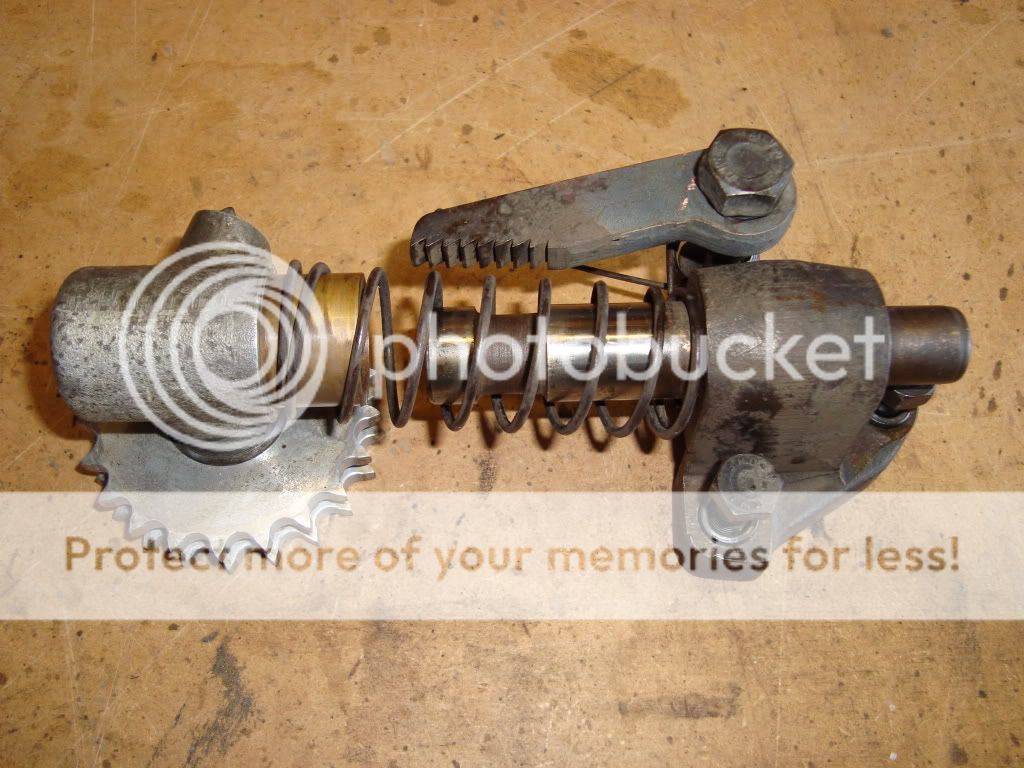

Great photos, very detailed and informing for enthusiastic learners

Great photos, very detailed and informing for enthusiastic learners