First, apologies for the delay in updating this thread - last update August 2014!

I ordered a new chassis from Richards, only 1 unfortunately

Galv prep prior to included mordant solution wash;

and etch priming,

followed by 2 coats of Chassis Black from Frosts.

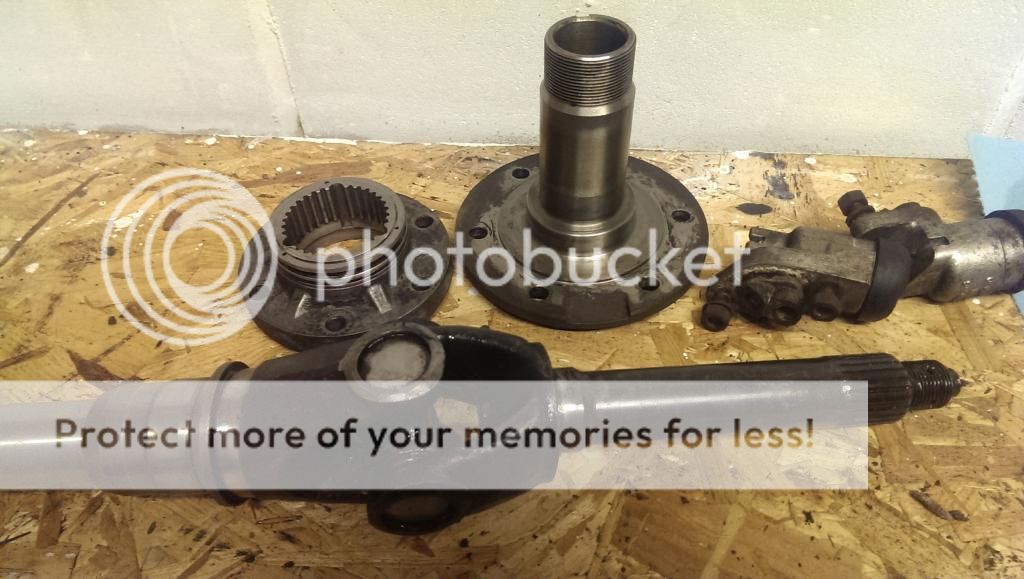

I have also got both front and back axles back together, although there is a bit more brake work to do, mostly getting the snail cams to work property, although this might wait until the rest of the system is back together.

I ordered a set of GB Springs parabolics as my standard springs were pretty shot. 2 leaf front, 3 leaf rear is what they advise, which seems to tally with the advice on here.

I got the springs on the axles and the assemblies back under the chassis

I have also fit a set of new Armstong standard dampers as they best suit my proposed use

I looked in to various brake line kit options and Automec kept coming up. I thought they might have been a spurious Chinese outfit but they are actually UK based. Here is some of the axles lines in, the rest will have to wait until the bulkhead is fitted.

So, on to the bulkhead... It s not in bad nick to be fair, but needs new footwells. I got some from that bloke on ebay (Les someone... I cant find him now). They're pretty good, ribbed toe plates and reinforcing plate in the drivers footwell.

So, the plan was to strip the bulkhead and get a local welder to get the new footwells in. Its looking like £400-£450 for this to happen, which I had resigned myself to. BUT, looking at this months Classic Land Rover mag they reference Classic Bulkheads

http://shop.classicbulkheads.com/index.php?route=product/product&path=61_75&product_id=98 who can do a fully repaired and galv'd one for £675 on an exchange basis by the look of it. I then found Mosside Land Rovers (find them on Facebook) who look like a good outfit. I'm waiting to hear back on prices. The basic welding is more than I though it would be and a fully galv'd one isnt much more, so I'm thinking lets just do it properly. It is more money than expected, but that seems to be par for the course

Can you lot have a look at me bulkhead and let me know what you think? I think the door posts, top corners and vents are ok, but the paint work is looking pretty shabby. Not bad for 34 years old.

New wiring loom required, and hopefully that will be the end of the big expenses. This thing is a bloody money pit