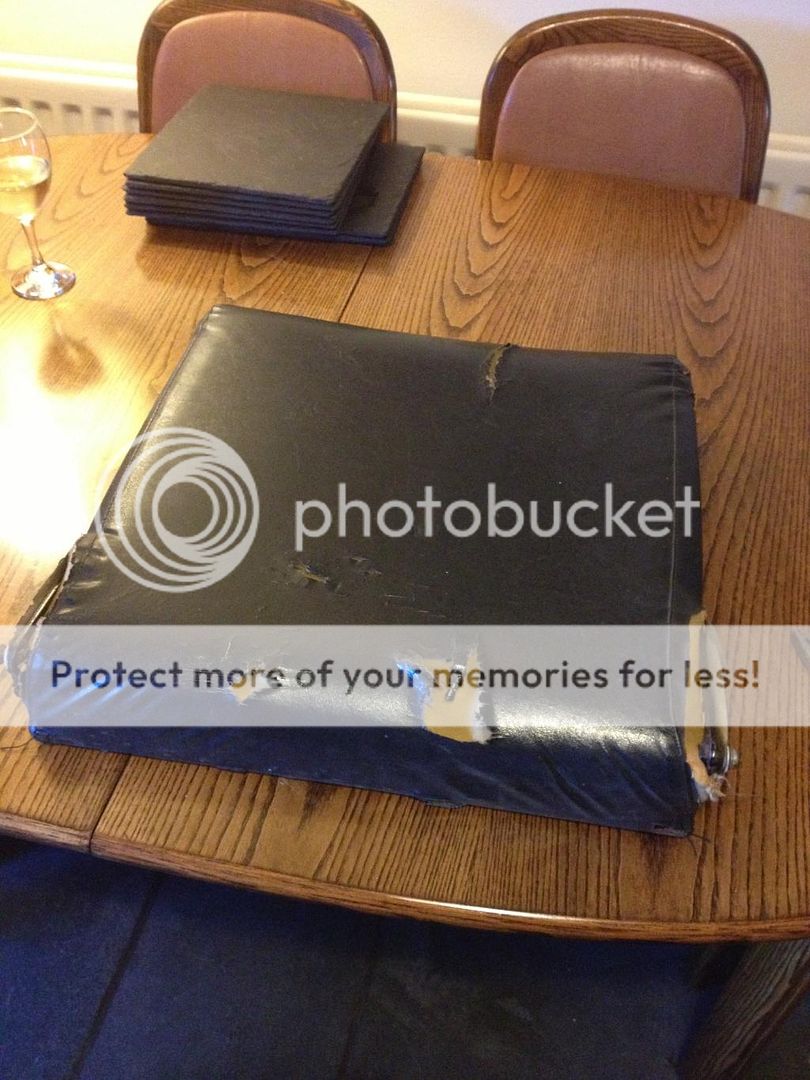

Spent most of yesterday and a few hours today at the workshop, here's a photo of the sill in it's finished state with the overlapping plates and the lip back in place.

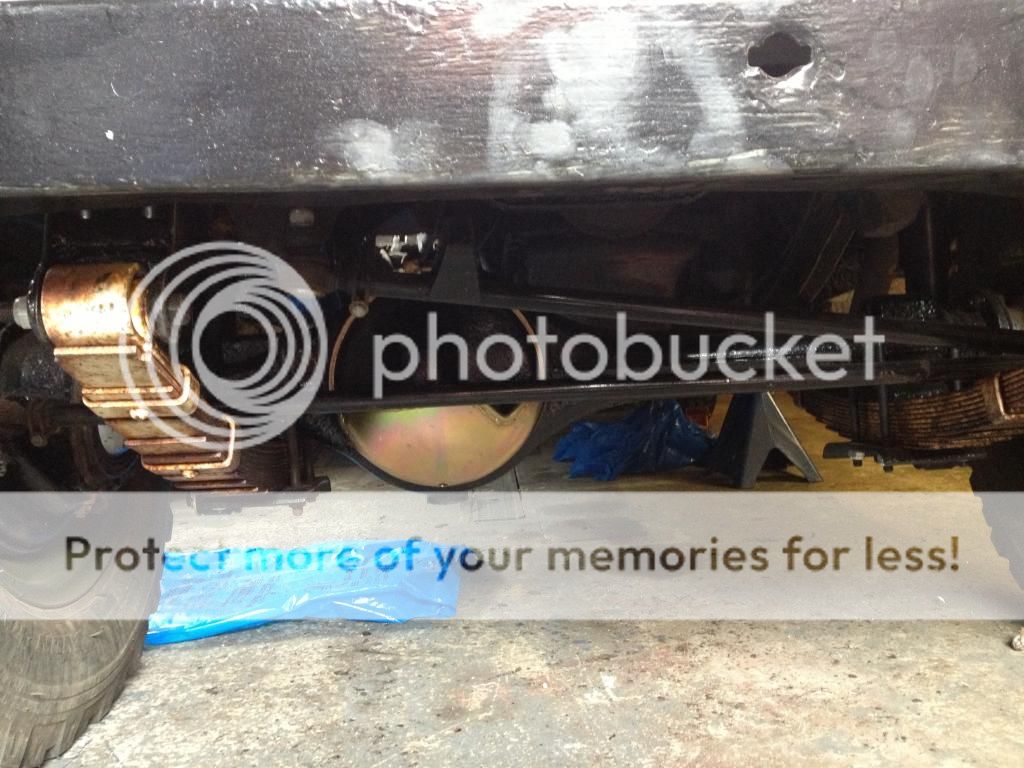

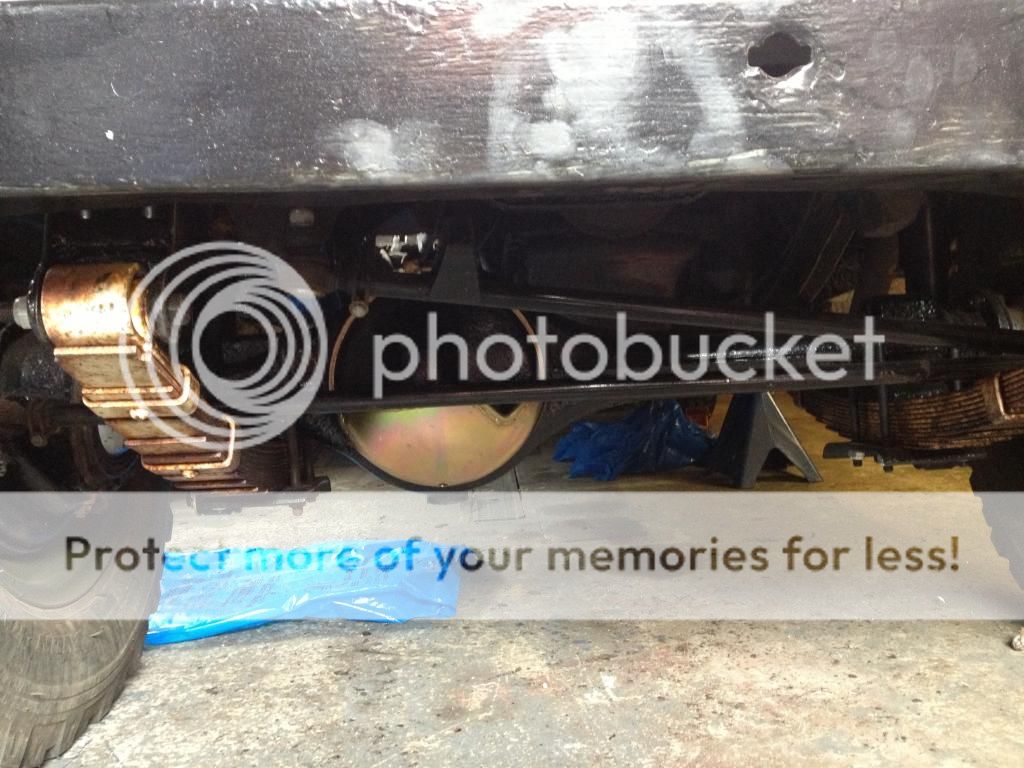

Got the door seals back onto the bulkhead on both sides and the diff guard fitted, had to remove the track rod to get it on and was expecting the ball joint to be a pain in the backside as they normally are but it came apart and went back together beautifully, job jobbed in 10 minutes.

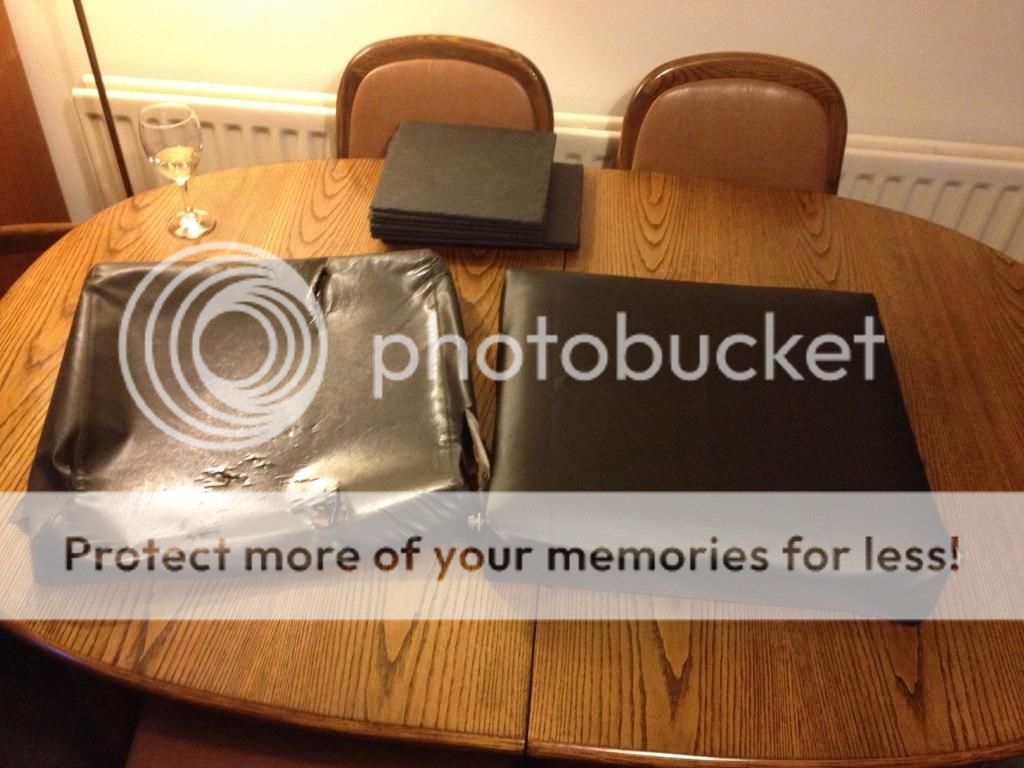

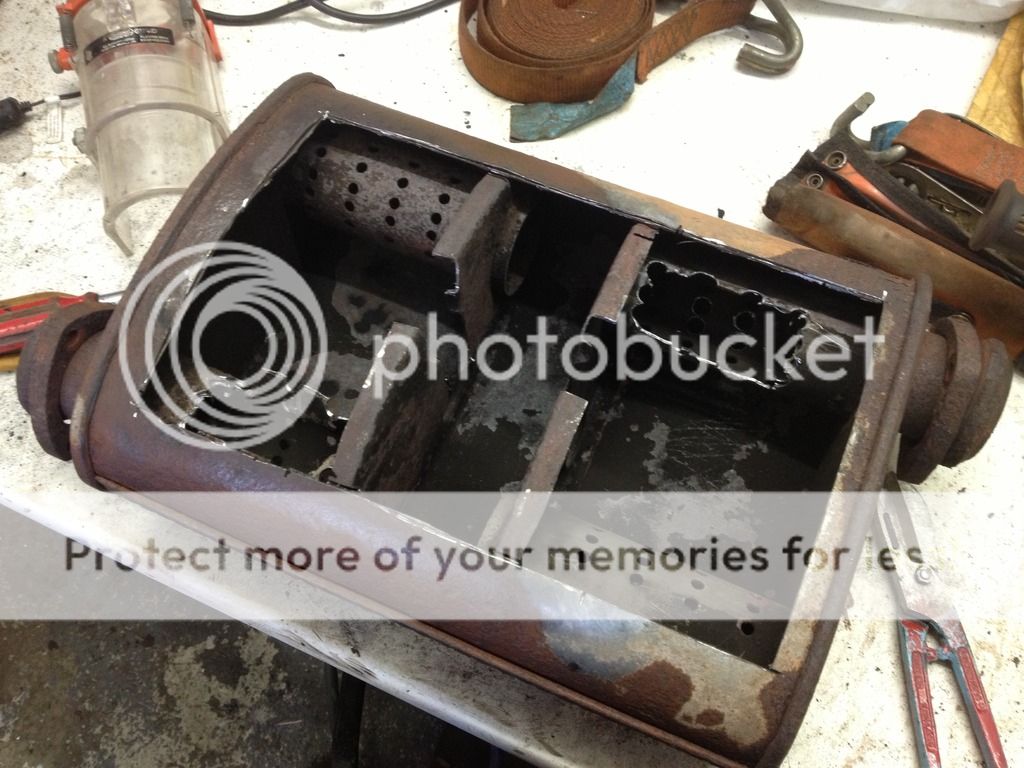

The main job for the weekend was sorting out this:

Which after a wire wheel looked like this

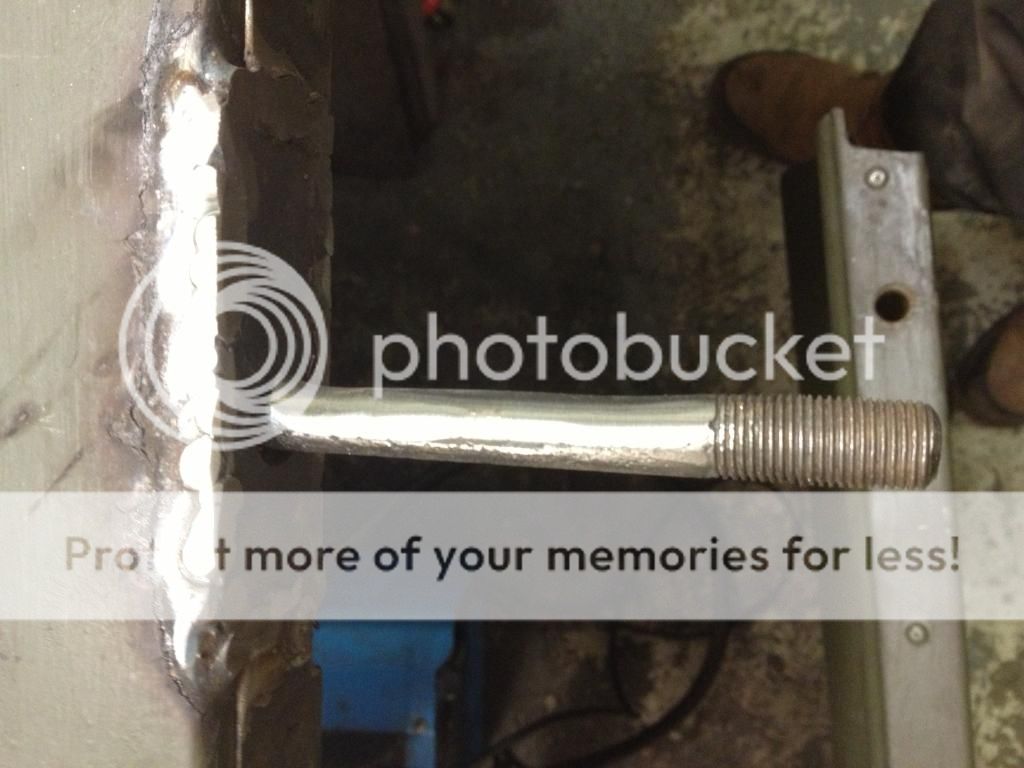

A plan was hatched and I went about bending a repair section to just plate over the top of what's there.

I stripped out the ribs and starting working on the other end which also got a plate over what's there.

Didn't have a huge selection of box section so I ended up using something which is a bit over engineered but at least I won't have to worry about it rotting out any time soon!

The solid aluminium rivets have been replaced with 6.4mm pop rivets to make sure everything stays put.

And after a lick of paint looks like this.

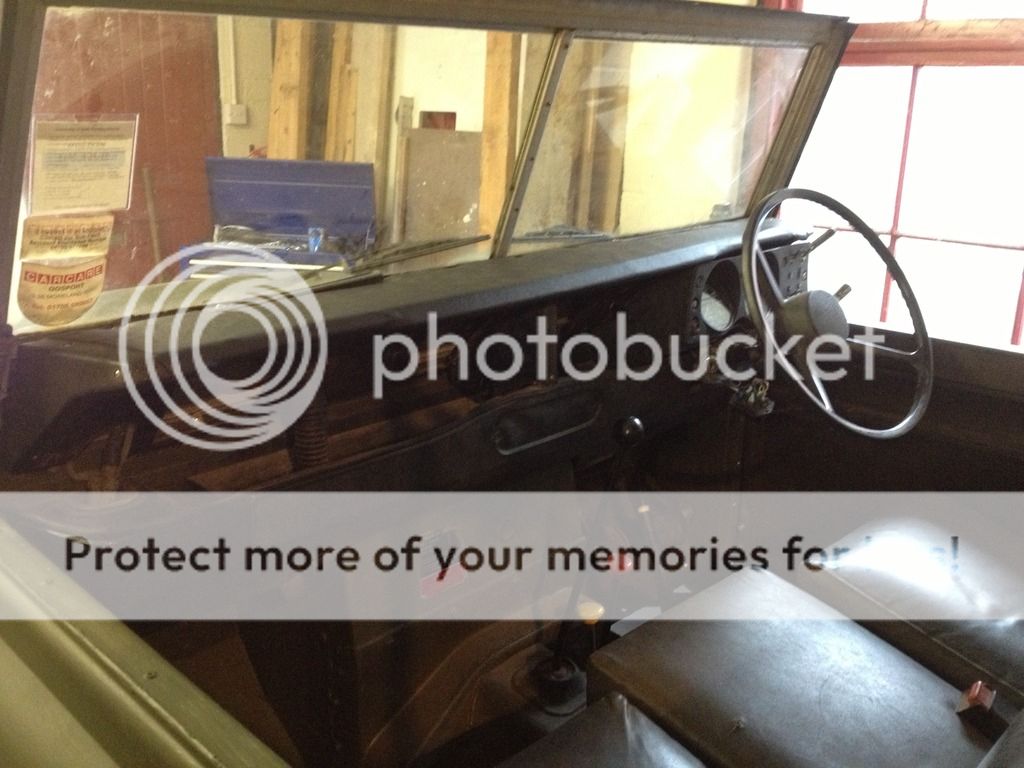

I also ended up helping a mate out on his landy and welding a couple of plates on his bulkhead for the MOT, was all going well untill the bonnet hinge failed and ripped out as we had the bonnet lent up against the wind screen so I could get access behind the brake pedal box. It turned out it was just held in with shed loads of filler....

Got the door seals back onto the bulkhead on both sides and the diff guard fitted, had to remove the track rod to get it on and was expecting the ball joint to be a pain in the backside as they normally are but it came apart and went back together beautifully, job jobbed in 10 minutes.

The main job for the weekend was sorting out this:

Which after a wire wheel looked like this

A plan was hatched and I went about bending a repair section to just plate over the top of what's there.

I stripped out the ribs and starting working on the other end which also got a plate over what's there.

Didn't have a huge selection of box section so I ended up using something which is a bit over engineered but at least I won't have to worry about it rotting out any time soon!

The solid aluminium rivets have been replaced with 6.4mm pop rivets to make sure everything stays put.

And after a lick of paint looks like this.

I also ended up helping a mate out on his landy and welding a couple of plates on his bulkhead for the MOT, was all going well untill the bonnet hinge failed and ripped out as we had the bonnet lent up against the wind screen so I could get access behind the brake pedal box. It turned out it was just held in with shed loads of filler....