Got a couple more hours work done tonight, first job was removing the driver's side vent flap and seal and seeing what horrors lay beneath...I was pleasantly suprised for once, there's a small bit of rot behind the bonnet hinge but that nothing that's not easily fixed!

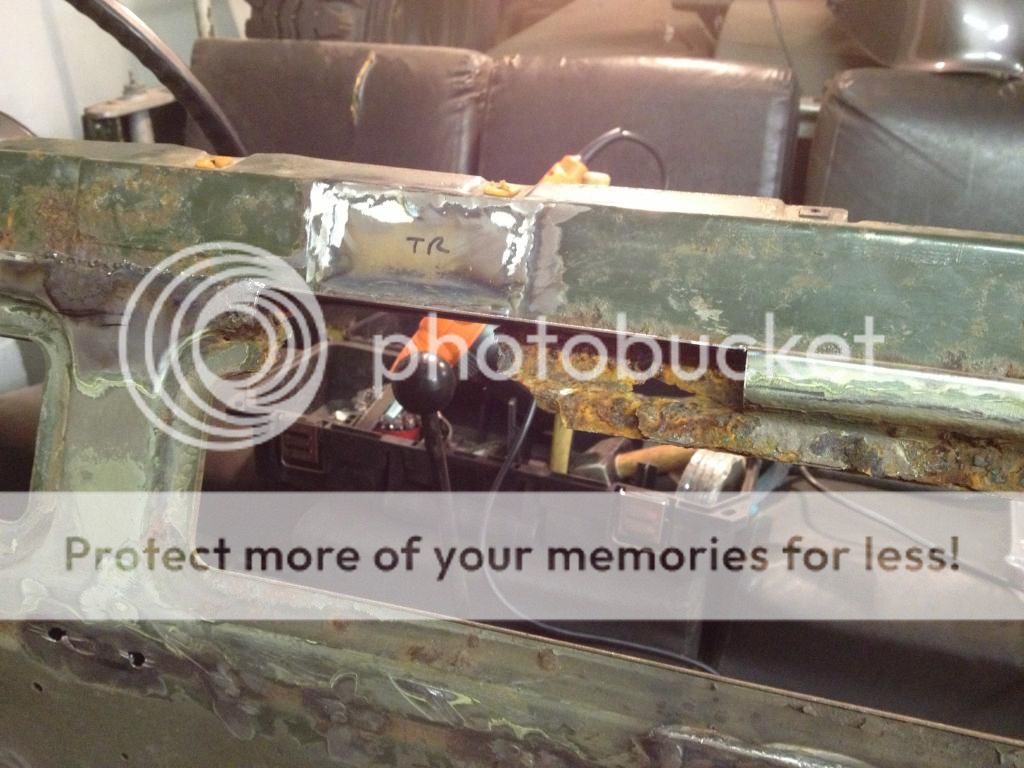

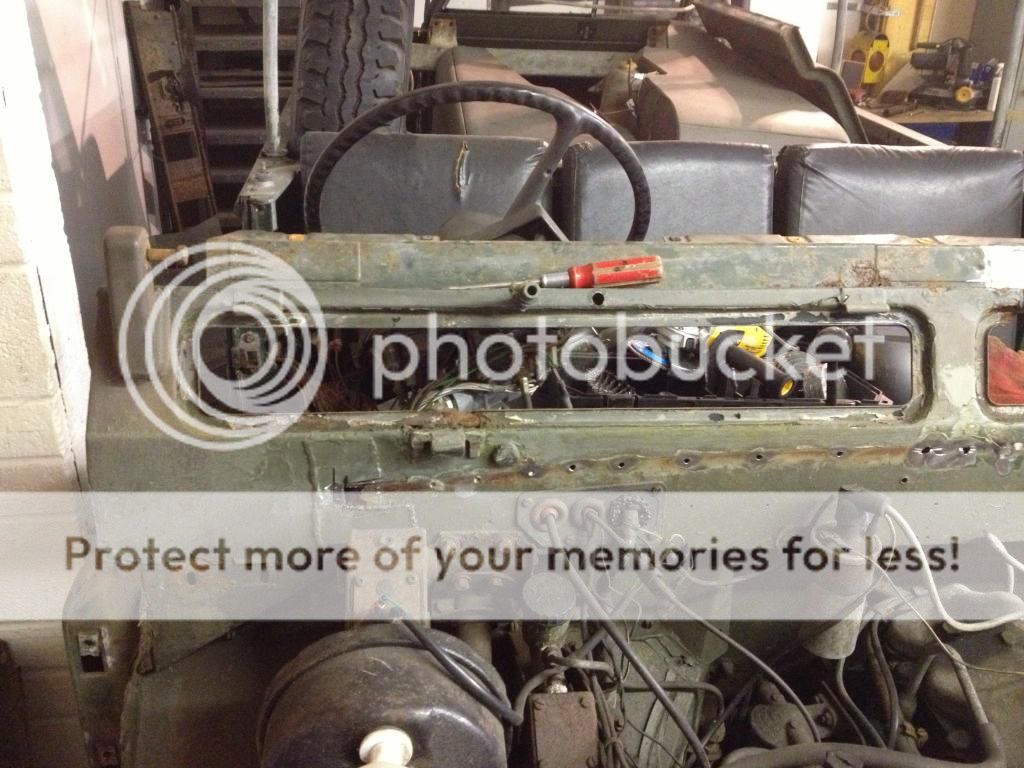

The main job I wanted to get done tonight was addressing this:

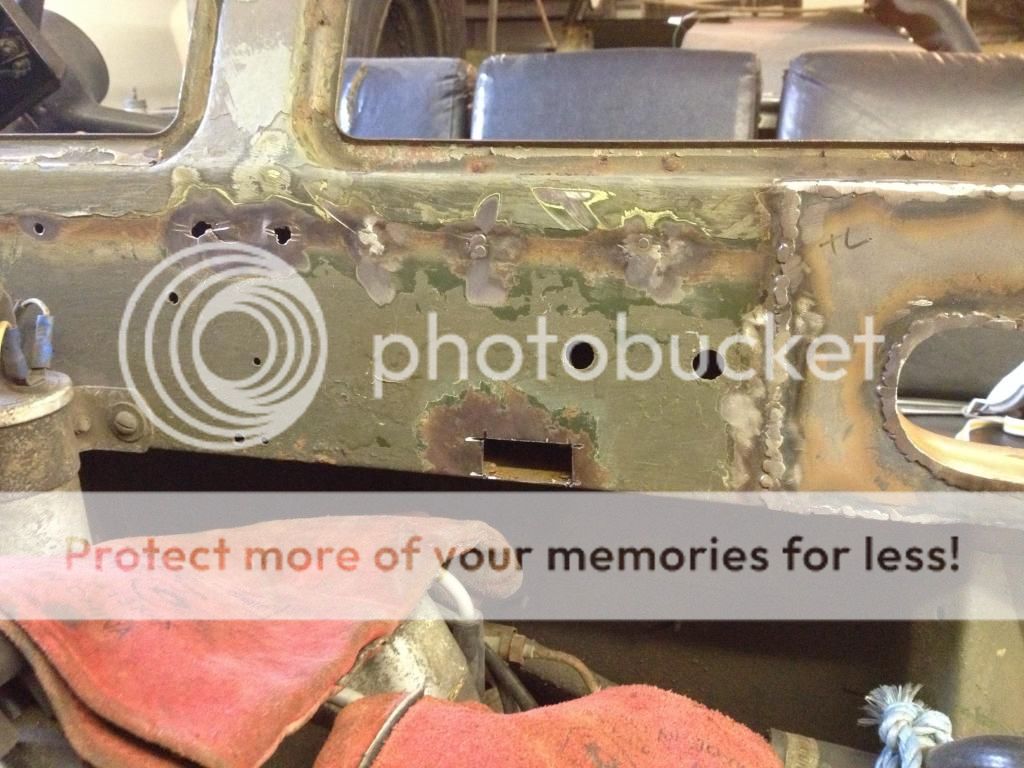

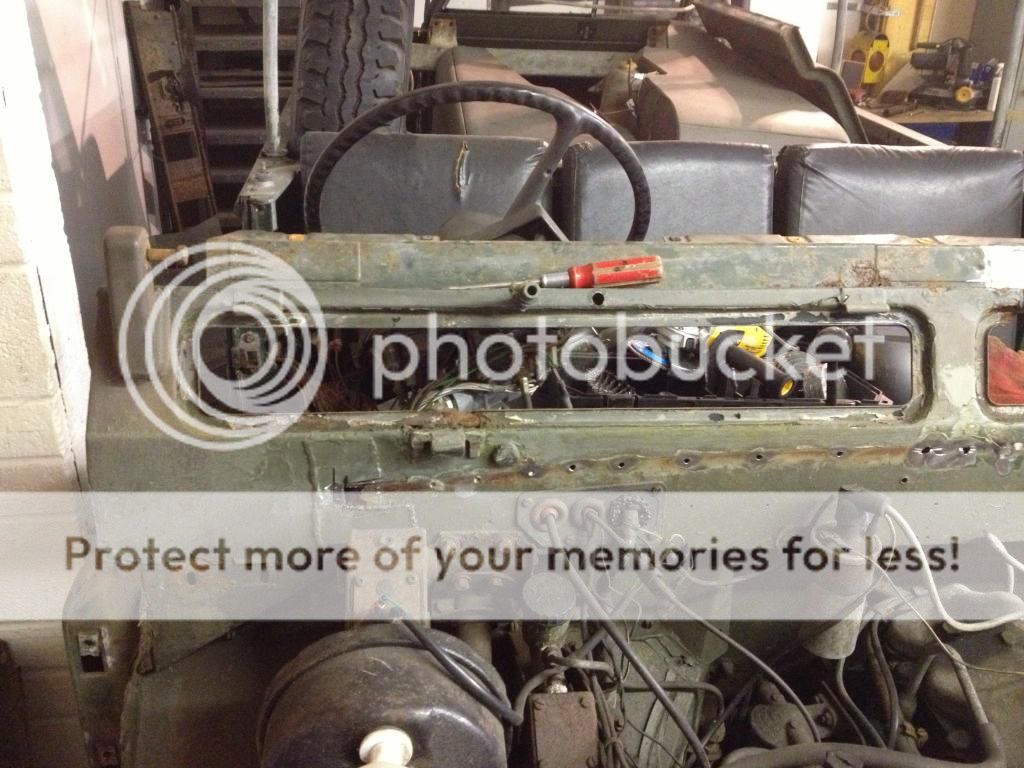

It's not pretty so out came the drill and the grinder and it quickly became this:

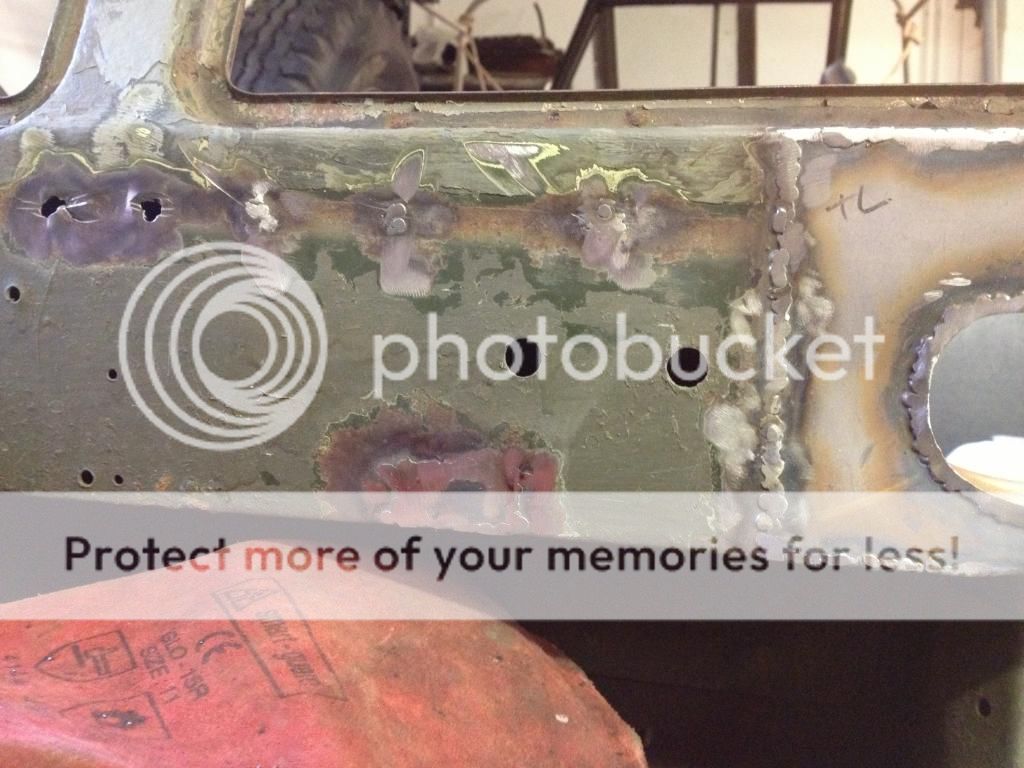

I welded a small flange on the new bit of metal that I put in last time to replace the missing bit (no pictures of that) and then cut and started welding in a new piece of steel to fill the hole.

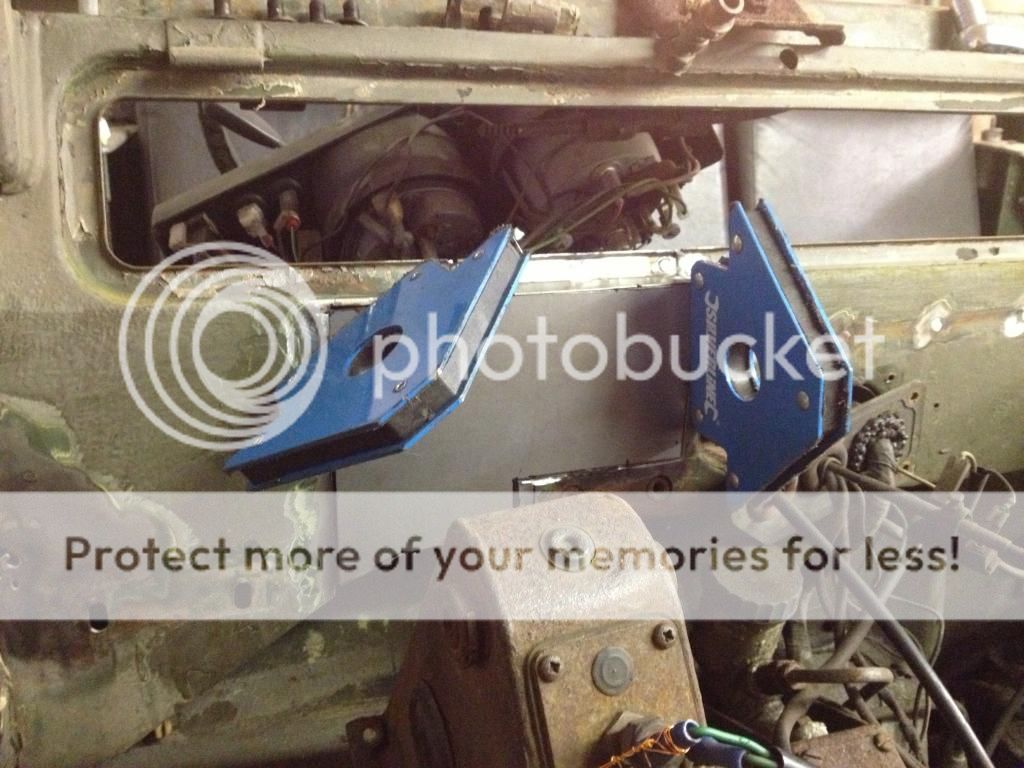

I need to chop out some of the vent seal channel on the passenger side and a little of the front face between the two vents but that's a job for next time. That's all for now folks.

The main job I wanted to get done tonight was addressing this:

It's not pretty so out came the drill and the grinder and it quickly became this:

I welded a small flange on the new bit of metal that I put in last time to replace the missing bit (no pictures of that) and then cut and started welding in a new piece of steel to fill the hole.

I need to chop out some of the vent seal channel on the passenger side and a little of the front face between the two vents but that's a job for next time. That's all for now folks.