Got a bit more technical today, i stripped down the front N/S swivel and assessed the damage, and replaced the stub axle.

Its one of those jobs i've known needed doing all along, and i was really wishing i could open it all up and find it factory fresh, but it wasn't as the photos show.

Pulled the wheel and drum off

I'll replace all the brake parts

The stub axle on this side was bolloxed up by a faulty FWH

this was weirdly a really hard part to get hold of, I would have rather bought the whole assembly as one, as i hate doing UJs, but famous 4 wanted £175 for the whole axle. Craddocks managed to find me just the stub plus a UJ for under £30

you can see the difference

the swivel assembly was a bastard to get off, i had to grind the bolts between the axle case in the end, which isn't easy to fit a grinder into, and it started to go dark half way through that.

i could see pretty quickly that the state of things inside wasn't good.

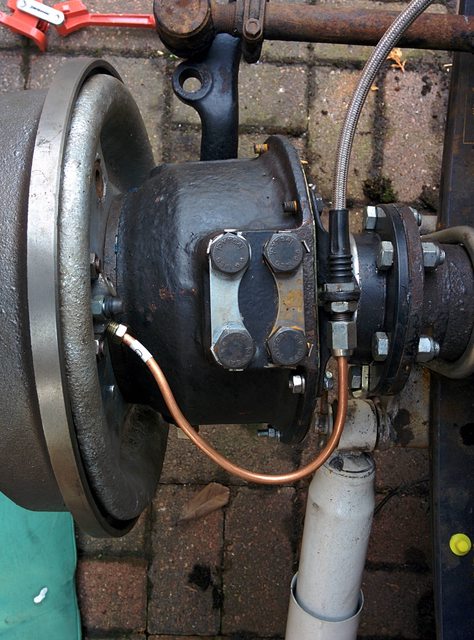

When i got that off, dismantling wasn't easy either, as someone had replaced each bolt with a variety different threads and sizes, that had all seized, holding the retaining plate in place.

the muck inside here was foul! oily, gritty and slimy, also found a few twigs

I'd love to be told that these balls are fine to keep using but i have a feeling they're maybe a little bit too pitted

That might be the heated windscreen budget blown for a while.

Anyway, got the casing and brake parts cleaned up, I scraped most of the muck off, then wirebrushed the rest before degreasing and priming in red oxide.

old meathooks are one of the most useful things i've found when painting

I also got the halfshaft separated and fitted a new joint and stub

No more pics of that, but it was relativly painless unlike when i did the propshaft ones, the cups went in nearly with just my fingers, and a little suggestion from a hammer and socket. No circlip pliers, so i improvised two used rivet shafts between a pair of normal pliers, and that worked ok.

The other job was fitting the catches for lock the catflap in place. They still need some work to line them up properly, but for now the cab is a relativity secure place to dump all my loose bits.

So does anyone know who sells the cheapest swivel ball sets?