Freetime101

Active Member

- Posts

- 358

- Location

- North East

Yay another rebuild thread

I initially started out fixing the handbrake ready for the MOT, but one thing lead to another and I've decided to jump in with both feet and take the old girl back to a bare chassis. I'm getting bored of fixing PO's bodges so have decided to strip it all and do it properly!

I expect this thread will be filled with questions from me, as well as photos. So for those that just want to keep up on progress I'll be documenting the progress on my blog www.meandmylandy.wordpress.com

As for the rest of you, brace yourself - stupid questions are coming!:rolly:

Now for the bit you're actually interested in:

I bought her back in November last year with the intention of just giving her a good clean and a lick of paint... but things were not that simple...

The first thing I did was fix the indicators, replace the speedo cable and remove the bullbar (now for sale if anybody wants it):

Next I needed a new tyre, the spare was also worn so I picked up a set of 5 Insa Turbo Rangers for the same price as 2 new tyres:

The only catch was the colour

Then with it being winter I decided to try and improve the heating, well, the airflow to be precise. There was plenty of heat coming into the passenger footwell but nothing making it's way over to the driver, or the windscreen. I discovered a gaping hole in the heater hose so most of the air was blowing into the engine bay, I fixed this with so good old fashioned duct tape:

Manky engine bay...

The air flow was still pretty poor so I removed the lower dash and fitted some drain pipes directing the hot air straight up to the windscreen. Sadly I never got around to taking a photo of this, but it was spectacular

I also needed to replace the drivers side windscreen washer as it was blocked, this was a right PITA and needed the top dash removing to get to the pipework.

And that was it until December, I had a few weeks of happy motoring and then disaster hit... I got water in the engine which led to a top end rebuild. I covered this in another thread so won't go into it again here. Everything was back together in January and I had another few months happy motoring.

With the arrival of the nice weather I took the opportunity to whip the roof: off

Paint the cappings:

And scrape the flaky paint off of the windscreen:

You'll notice the roof rack has also been removed, this was the missus' idea - I'm not so sure...

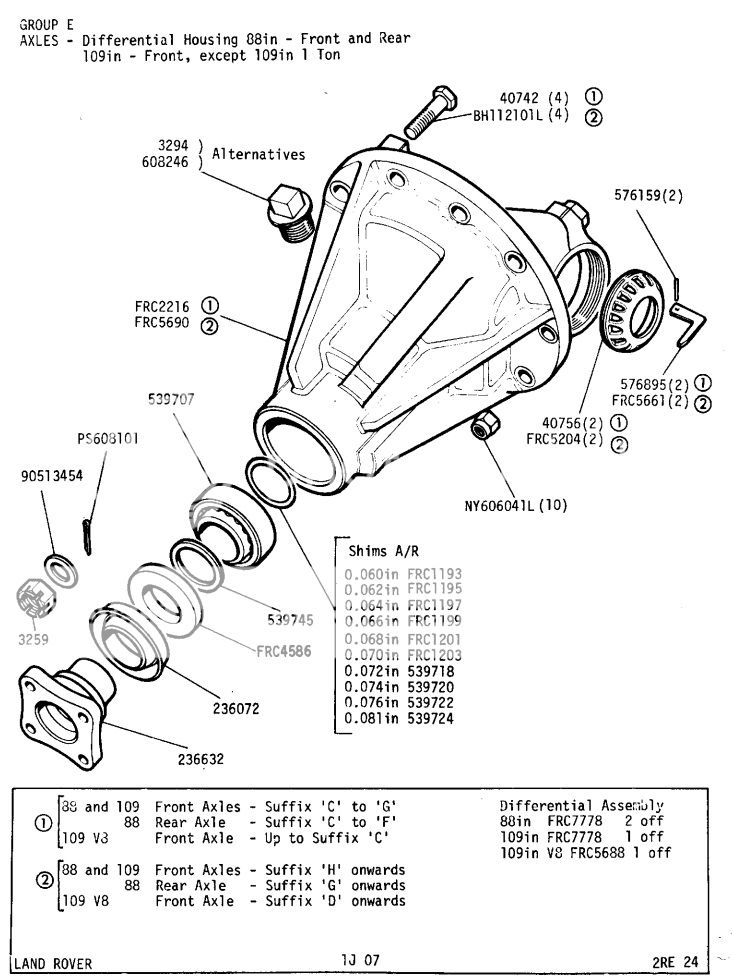

I even managed a trip out laning but unfortunately picked up quite a bad oil leak on the way home... The MOT was due that week and I had a long list of jobs to do, and so we ended up here

I initially started out fixing the handbrake ready for the MOT, but one thing lead to another and I've decided to jump in with both feet and take the old girl back to a bare chassis. I'm getting bored of fixing PO's bodges so have decided to strip it all and do it properly!

I expect this thread will be filled with questions from me, as well as photos. So for those that just want to keep up on progress I'll be documenting the progress on my blog www.meandmylandy.wordpress.com

As for the rest of you, brace yourself - stupid questions are coming!:rolly:

Now for the bit you're actually interested in:

I bought her back in November last year with the intention of just giving her a good clean and a lick of paint... but things were not that simple...

The first thing I did was fix the indicators, replace the speedo cable and remove the bullbar (now for sale if anybody wants it):

Next I needed a new tyre, the spare was also worn so I picked up a set of 5 Insa Turbo Rangers for the same price as 2 new tyres:

The only catch was the colour

Then with it being winter I decided to try and improve the heating, well, the airflow to be precise. There was plenty of heat coming into the passenger footwell but nothing making it's way over to the driver, or the windscreen. I discovered a gaping hole in the heater hose so most of the air was blowing into the engine bay, I fixed this with so good old fashioned duct tape:

Manky engine bay...

The air flow was still pretty poor so I removed the lower dash and fitted some drain pipes directing the hot air straight up to the windscreen. Sadly I never got around to taking a photo of this, but it was spectacular

I also needed to replace the drivers side windscreen washer as it was blocked, this was a right PITA and needed the top dash removing to get to the pipework.

And that was it until December, I had a few weeks of happy motoring and then disaster hit... I got water in the engine which led to a top end rebuild. I covered this in another thread so won't go into it again here. Everything was back together in January and I had another few months happy motoring.

With the arrival of the nice weather I took the opportunity to whip the roof: off

Paint the cappings:

And scrape the flaky paint off of the windscreen:

You'll notice the roof rack has also been removed, this was the missus' idea - I'm not so sure...

I even managed a trip out laning but unfortunately picked up quite a bad oil leak on the way home... The MOT was due that week and I had a long list of jobs to do, and so we ended up here