chrimcne

Active Member

- Posts

- 200

- Location

- Mid Suffolk

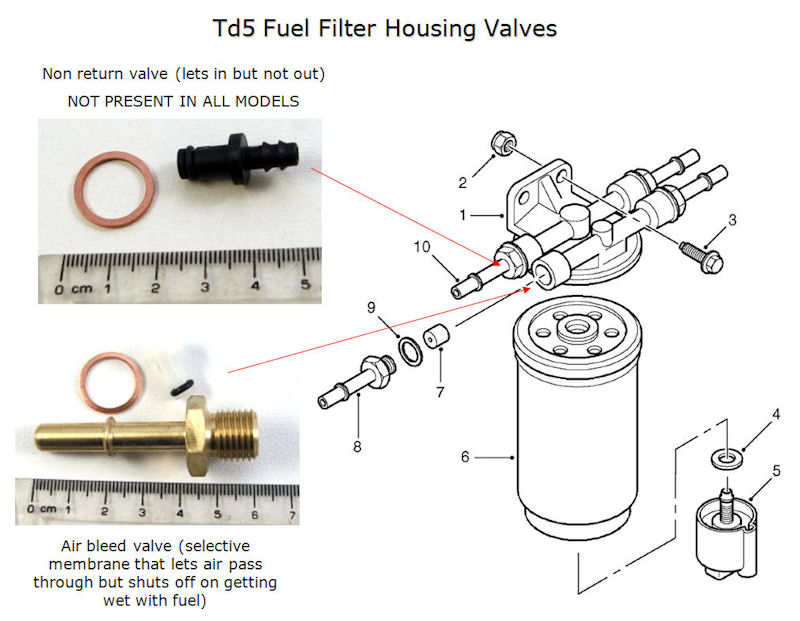

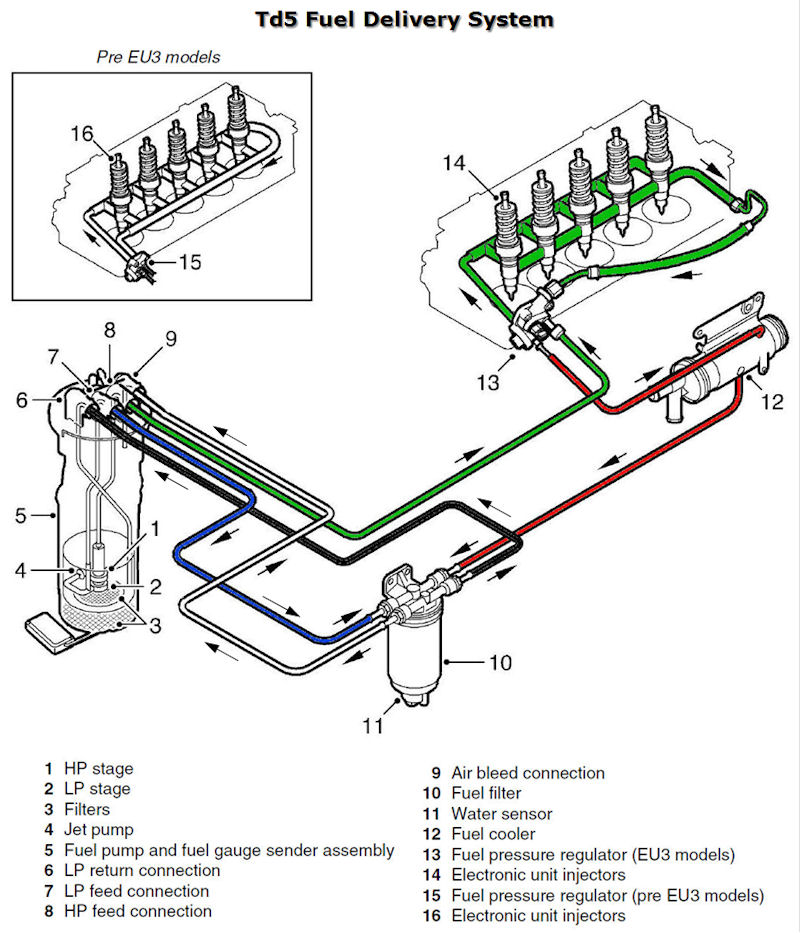

Hi - currently have to wait for the air to be purged from the fuel system every morning and if the car is left standing for any longer than about and hour. Have replaced the pump, filter (only one O ring in the middle) and the regulator. The car sits on a clean surface and there are no signs of a leak anywhere.

Anybody any ideas what is happening, car runs fine when started.

Thanks

Anybody any ideas what is happening, car runs fine when started.

Thanks