xDParis64

Member

- Posts

- 26

Hey all!

I have been working on my land rover today.

For context I have a Freelander 1 1.8 petrol along with a 2.0 TD4 that has rust out of the wazoo so it is a donor parts car (Unable to pass MOT or reasonably be repaired).

However I think I have had a huge issue now... I've had a shaky prop for a while now and the VCU test I did failed as it just spun with no resistance at all, I was going to take the VCU out and send it to Bell engineering to ensure the VCU was okay, however upon removal of the prop I have no drive... The car will not go forward... or back... which means I have been in rear wheel drive this whole time and is likely a massive factor to the lack of power and no resistance VCU test, the shakiness was from the bearings which are being replaced.

Just a question for everyone, as the previous owner 100% drove this with a broken VCU is it likely the IRD has gone kaput? if so;

What is a likely repair?

Should I just replace the whole IRD?

Can I take the IRD from the TD4 that is only FWD so I know it works in that aspect and fit it to my petrol one?

Can I check the IRD?

Are there any other reasons for this? (Unlikely to be the clutch as I moved its parked spot to be closer to parts car, only happened once prop removed.)

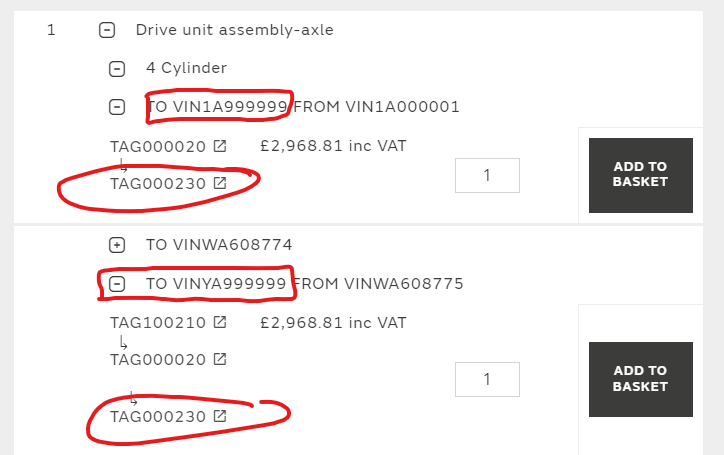

If the IRD needs replacing and cannot use the TD4 one (I did check the part numbers for both VIN's are the same) should I go with 2nd hand or recon, I don't really want to purchase one from bell for 600... before! VAT

Any help would be massively appreciated!

I have been working on my land rover today.

For context I have a Freelander 1 1.8 petrol along with a 2.0 TD4 that has rust out of the wazoo so it is a donor parts car (Unable to pass MOT or reasonably be repaired).

However I think I have had a huge issue now... I've had a shaky prop for a while now and the VCU test I did failed as it just spun with no resistance at all, I was going to take the VCU out and send it to Bell engineering to ensure the VCU was okay, however upon removal of the prop I have no drive... The car will not go forward... or back... which means I have been in rear wheel drive this whole time and is likely a massive factor to the lack of power and no resistance VCU test, the shakiness was from the bearings which are being replaced.

Just a question for everyone, as the previous owner 100% drove this with a broken VCU is it likely the IRD has gone kaput? if so;

What is a likely repair?

Should I just replace the whole IRD?

Can I take the IRD from the TD4 that is only FWD so I know it works in that aspect and fit it to my petrol one?

Can I check the IRD?

Are there any other reasons for this? (Unlikely to be the clutch as I moved its parked spot to be closer to parts car, only happened once prop removed.)

If the IRD needs replacing and cannot use the TD4 one (I did check the part numbers for both VIN's are the same) should I go with 2nd hand or recon, I don't really want to purchase one from bell for 600... before! VAT

Any help would be massively appreciated!